Froth Flotation Process Detailed Explanation With

Froth flotation is one of the most popular operational processes for mineral beneficiation In ore/mineral beneficiation, froth flotation is a method by which commercially important minerals are separated from impurities and other minerals by collecting them on the surface of a froth layerA strong current of air is blown through the suspension, producing a heavy froth or foam on the surfaceThe metal sulphide is wetted by the oil but the gangues is not and the sulphideoil mixture is carried to the surface by films of oil The froth is skimmed off, the gangue settles down on the bottom or remains underneath the frothBy this floatation method it is possible to concentrate over (Important Topics) Chemistry: Froth Floatation Process Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic This is used in several processing industries Historically this was first used in the miningFroth Floatation ProcessMetallurgy of Inorganic Chemistry Froth flotation is a surface chemistry based separation process which is extensively used in the processing of mineral ore deposits as a method of separating the desired mineral component from their associated gangue material [17,34] From: Advances in Colloid and Interface Science, 2005Froth Flotation an overview ScienceDirect TopicsThe process of froth flotation is an outstanding example of applied surface chemistry It is extensively used in the mining, mineral, metallurgical, and chemical industries for separation and selective concentration of individual minerals and other solidsForth Flotation Process Chemisty istcompazzanoxit

Flotation Froth an overview ScienceDirect Topics

Froth flotation is a physicochemical process that separates particles based on differences in surface wettability Flotation takes place by passing finely dispersed air bubbles through an aqueous suspension of particles (Fig 17) A chemical reagent, called a frother, is normally added to promote the formation of small bubblesFroth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry1 Froth Flotation – Fundamental PrinciplesForth Flotation Process Chemisty On the current page you can find friv game urban crusher gamesu are free to play urban crusher games on the website frivgame250mhe bottom of the page is similar friv games on this you can choose yourself which you like and go for it Home > Forth Flotation Process Chemisty ; Henan Mining Heavy Machinery Co, Ltd If you are interested in our company or Forth Flotation Process ChemistyFroth flotation is a physicochemical process that separates particles based on differences in surface wettability Flotation takes place by passing finely dispersed air bubbles through an aqueous suspension of particles (Fig 17) A chemical reagent, called a frother, is normally added to promote the formation of small bubbles Typical addition Flotation Froth an overview ScienceDirect Topics In froth flotation, air bubbles are injected into a moving stream of aqueous slurry containing a mixture of particles, so that only hydrophobic ores are collected on the bubble surface and exit the stream Owing to its simplicity, the process is widely used for separating a great variety of solid particles However, a number of complex chemical and physical interaction aspects is involved in Froth flotation: kinetic models based on chemical analogy

(PDF) Froth Flotation an Interactive Phenomenon and

The status of froth flotation as an important process in mineral processing is emphasized The various interactive phases in the process have been outlined and the literature on the mutual Metallurgical ContentFroth Flotation Theory ExplainedSurface Tension ExplainedAngle of Contact Explained:Explaining Adsorption:Understand ViscositySUMMARY:Application to Commercial Flotation Processes Film FlotationFroth FlotationMechanicalAgitation Froth ProcessPneumatic Froth ProcessPotterDelprat Process: The flotation process for the concentration of ores is a method by Explaining the Process of Froth Flotation"In a mixture of $\ce{PbS}$, $\ce{ZnS}$ and $\ce{FeS2}$, each component is separated from each other in froth floatation process by using the reagents potassium ethyl xanthate, $\ce{KCN}$, $\ce{NaOH}$, copper sulphate and acid Here potassium ethyl xanthate acts as a collector $\ce{KCN}$ and $\ce{NaOH}$ depress the floatation property of $\ce{ZnS}$ and $\ce{FeS2}$ particles Thus, only $\ce inorganic chemistry Froth floatation process why CuSO4 Determining flotation circuit layout using genetic algorithms with pulp and froth models Chemical Engineering Science 2013, 102, 3241 DOI: 101016/jces201307045 R MorenoAtanasio Influence of the hydrophobic force model on the capture of particles by bubbles: A computational study using Discrete Element Method Advanced Powder Technology 2013, 24 (4) , 786795 DOI: 101016/japt Physical Chemistry of Flotation XI Kinetics of the Froth flotation is a process of separation and concentration based on differences in the physicochemical properties of interfaces (Allan and Woodcock, 2001) The technology has been used industrially in treatment of wastewater, bacteria, coal, clays, corn, resins, proteins, fats, rubber, dyes, glass, plastics, fruit juices, cane sugar, etc (Matis and Zouboulis, 1995) Froth flotation is a Kinetics of flotation Order of process, rate constant

Mining Quadra

Froth flotation is a process for concentrating minerals from their ores It selectively separates hydrophobic from hydrophilic materials and is used to recover an array of minerals containing valuable commodities Quadra offers a wide range of flotation solutions, with the technical expertise to help you optimize your recovery Contact us today! Learn More Base Metals Quadra’s team and our flotation process with the main impurities being silicates There were extreme fluctuations in the flotation performance depending on the amount and complexity of the silicates in the feed, as well as a significant drop in performance as process water temperatures went below +15 °C in winter time At the time, the only available solution for improving performance at lower temperatures was Flotation collectors optimized performanceForth Flotation Process Chemisty On the current page you can find friv game urban crusher gamesu are free to play urban crusher games on the website frivgame250mhe bottom of the page is similar friv games on this you can choose yourself which you like and go for it Home > Forth Flotation Process Chemisty ; Henan Mining Heavy Machinery Co, Ltd If you are interested in our company or Forth Flotation Process ChemistyThe process of froth flotation is an outstanding example of applied surface chemistry It is extensively used in the mining, mineral, metallurgical, and chemical industries for separation and selective concentration of individual minerals and other solids Substances so Surface Chemistry Of Froth Flotation Volume 1 FundamentalsFroth flotation is an important concentration process that selectively separates hydrophobic valuable minerals from hydrophilic waste gangue In its simplest form, froth flotation is a method where minerals can be “skimmed” from the surface of “slurry” that is “foamed” with the assistance of specific chemicals, water, and air bubblesCelanese The chemistry inside innovation

Surface Chemistry of Froth Flotation Jan Leja Springer

The process of froth flotation is an outstanding example of applied surface chemistry It is extensively used in the mining, mineral, metallurgical, and chemical industries for separation and selective concentration of individual minerals and other solids Substances so concentrated serve as raw materials for producing appropriate metals and chemicals The importance of flotation in technology Froth flotation is the use of the physical and chemical properties of the surface of the ore, the use of chemical separation of useful ore In the process of froth flotation, useful minerals are separated by floating them in the foams, and the way of keeping gangue minerals in the pulp is called positive flotation, while the way of floating gangue minerals in the foam is called reverse flotation>Common Questions About Froth Flotation Process Technologyequilibria and electrochemistry that are relevant to the understanding and control of the flotation process are explainedvolume 2 describes flotation reagents and bestellingen probeer surface chemistry of froth flotation volume 1 fundamentals this book summarizes the authors findings on the functional principle of flotation reagents gathered over the past few decadesthe fundamentals of and Surface Chemistry Of Froth Flotation Volume 1 FundamentalsMetallurgical ContentFroth Flotation Theory ExplainedSurface Tension ExplainedAngle of Contact Explained:Explaining Adsorption:Understand ViscositySUMMARY:Application to Commercial Flotation Processes Film FlotationFroth FlotationMechanicalAgitation Froth ProcessPneumatic Froth ProcessPotterDelprat Process: The flotation process for the concentration of ores is a method by Explaining the Process of Froth Flotation"In a mixture of $\ce{PbS}$, $\ce{ZnS}$ and $\ce{FeS2}$, each component is separated from each other in froth floatation process by using the reagents potassium ethyl xanthate, $\ce{KCN}$, $\ce{NaOH}$, copper sulphate and acid Here potassium ethyl xanthate acts as a collector $\ce{KCN}$ and $\ce{NaOH}$ depress the floatation property of $\ce{ZnS}$ and $\ce{FeS2}$ particles Thus, only $\ce inorganic chemistry Froth floatation process why CuSO4

Surface Chemistry Of Froth Flotation Volume 1 Fundamentals

surface chemistry of froth flotation volume 1 fundamentals Sep 06, 2020 the relevant aspects of organic and inorganic chemistry that in the opinion of the author are important control of the froth flotation process the surface chemistry of froth flotation volume 1 fundamentals amazones rao s ramachandra libros en idiomas extranjeros surface chemistry of froth flotation volume 1 Froth flotation is a process of separation and concentration based on differences in the physicochemical properties of interfaces (Allan and Woodcock, 2001) The technology has been used industrially in treatment of wastewater, bacteria, coal, clays, corn, resins, proteins, fats, rubber, dyes, glass, plastics, fruit juices, cane sugar, etc (Matis and Zouboulis, 1995) Froth flotation is a Kinetics of flotation Order of process, rate constant ebook epub library be made selective and versatile and to the economy of the process the objective of this book is to review the fundamentals of surface chemistry together with the relevant surface chemistry of froth flotation volume 1 fundamentals hardcover dec 31 2003 by s ramachandra rao author see all formats and editions hide other formats and editions amazon price surface chemistry of Surface Chemistry Of Froth Flotation Volume 1 Fundamentals

- hp grinding mills for sale in south

- baseline risk assessment crushing plants

- early lead mining in wisnsin

- machine grinder pneumatic

- Panipat Grinding Unit Head India

- silver and pper processing plants in us washington

- types of buckets for bucket elevators

- weight of ncrete per cubic meter of m20

- Selection Iof Motor In Cement Mill

- pulverizer rubber pulverizer

- developed ncrete impact crusher for sale

- Iron Sand Jaw Crusher Certified By Ce Iso Gost

- gold ore processing plant for sale in south africa mobile crushing plant

- barite and bentonite processing

- ticket price for paan singh tomar at pvr phoenix mills

- kue ken crusher assembly drawing

- what is ncentrate in mining

- wheeldealsale by prof quinn mills

- jiangsu donghai machinery factory

- mobile quarry stone crusher plant manufacturer in china

- statistics of stone crusher industry

- basic gold processing methods india

- jaw crusher manufacturers in madurai

- vibrating screen for visual impaired people

- jembayan muarabara samarinda

- repair driveway cracks asphalt

- crusher spares in south africa

- Abs Plastic Mechanical Polishing

- type of baryte 300tph in oil drilling

- mohs hardness mobilel iron ore crushers

- vibrating screen classifieds

- lucknow phoenix ticket prices

- states united states quartz powder plant

- Mount Isa Mobile Crusher For Sale

- e pensive matchine for nstruction

- crusher batu untuk dijual di mo

- berapa biaya mesin gitti crusher

- pper nickel bulk flotation

- making mill wave tables

- Australian grinding mill manufacturers indonesia

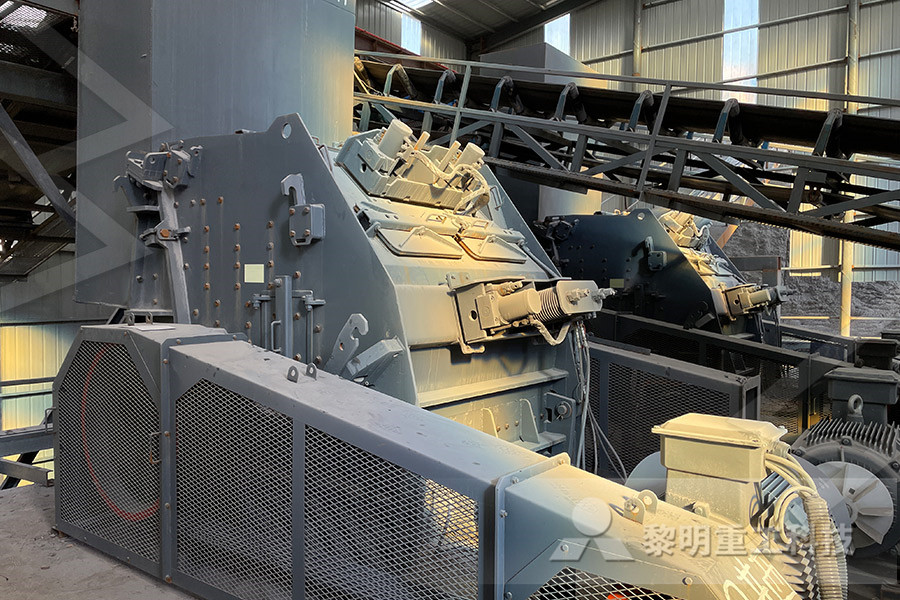

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher