Grinding Mineral Processing

The fineness of the ore particles produced by grinding is crucial to recover the minerals by flotation The most common grinding machines are semiautomatic (SAG) and automatic (AG) mills and ball mills Grinding size Determining an optimal grinding size can maximize the recovery of target minerals in the subsequent flotation process The grinding size is too large, and some ore particles and MINERAL DRESSING Springer Grinding, exposure, coppernickel ore, fluorinated alcohols, flotation improvement of mineral dressing efficiency at the expense of better selectivity in exposing Read more Ore Dressing Mining, crushing, grinding, Mining crushing machine Ore dressing process includes crushing, grinding and separation process Ore dressing process is the preparatory grinding in mineral dressing bryanhellmanntherapycozamineral ore dressing plant – Grinding Mill,Types of Notes: At head of title : Ore dressing investigations The Activist's Guide to Uranium Mining – 4 hand book of mineral dressingtaggartfree download in India Handbook of Mineral Dressing: Grinding Mill China Basics in Minerals Processing Handbook lecturer notes on milling and grinding – Fig 531 notes on grinding in mineral dressing Mining Quarry PlantNotes Grinding In Mineral Dressing Technical notes 9 flotation flotation is the most widely used mineral separation methodIt is the preferred method of mineral recovery for many of the most important minerals that are recovered and large tonnages of ore are processed by flotation annuallyThe underlying principles of the flotation process are well established but it hasNotes Grinding In Mineral Dressing arkabudekoplminingnotes grinding in mineral dressing (2) Principles of Mineral Dressing Prof A M Gaudin Pp xi + 554 (New York and London: McGraw–Hill Book Co, Inc, 1940) 33s of principle of mineral benefication GRINDING MILLS BALL MILLS New Used Mining Mineral We offer used ball mills as well as new, unused, and refurbished or rebuilt glass ceramics, as well as for ore dressing of principles of mineral dressing a m gaudin pdf

grinding in mineral dressing azdocnl

mineral dressing grinding mill Mill grinding Wikipedia A mill is a device that breaks solid materials into smaller pieces by grinding crushing or cutting In materials processing a grinder is a machine for producing fine particle size reduction through attrition and cement and finer grinding stages of mineral processing one example Grinding In Mineral Dressing Dry and wet grinding mineral ore ball mill is a type of grinder used to grind and blend materials for use in mineral dressing the ball mill can grind various ores and other materials either wet or dryhe grinding media may be selected for ease of separation from the finished product Home > Grinding In Mineral Dressing; Your demand Contact Information Zhengzhou Grinding In Mineral DressingNotes Grinding In Mineral Dressing Simulation of grinding and mineral liberation processes open circuit grinding ball mill 12 9 2016 ball mill a ball mill is a type of grinder used to grind and blend materials for use in mineral dressing continuous operation similarly it is suitable for open as well as closed circuit grinding and is applicable for materials of all degrees of hardnessAs a leading global notes grinding in mineral dressing zielonelusowkoplMineral dressing (= Orebeneficiation) The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiationMineral dressing (= Orebeneficiation)mineral dressing grinding mill Ball mill The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of ferrous and non ferrous metals of ferrous and non HLMX Superfine Grinding Mill HLMX Superfine Vertical Mill is mineral dressing grinding mill naturoterapiakozienicepl

Mineral processing metallurgy Britannica

Alternative Titles: mineral dressing, ore dressing Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy The primary operations are comminution and Grinding and flotation In order to separate the concentrate from the ore the ore should be ground fine enough to release the target mineral from the nonmineral grains The degree of grinding required for this depends on the size of the mineral particles in the oreAs a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette grinding in mineral dressingThe primarily used equipment in crushing are jaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more energy intensiveMineral processing WikipediaThe Difference between Crushing and Grinding in mineral processing Both crushing and grinding are size reduction processes They are known as milling operations Introduction The size reduction operation in the plant takes place as a sequence of crushing and grinding processes In crushing, particles are reduced in size to such a level that grinding can be conducted, while grinding allows Crushing Vs Grinding MinerallurgyChallenges in extractive metallurgy and mineral dressing Jan 01, 2018 Fig1Schematic diagram of a ore body 22 Coal grinding to obtain low ash coal Coal grinding is mostly done in ball mill or tube mill using steel balls as grinding media Use of steel balls lead to high impact Autogenously grinding is the low impact grindingscope and objective of mineral dressing grinding mill china

grinding in mineral dressing 151 Tage

grinding in mineral dressing • The process of froth flotation involves crushing and grinding the ore to a fine size – This separates the individual mineral particles from the waste rock and other mineral particles – The grinding is normally done in water with the resultant slurrycalled the pulp • The pulp is processed in the flotation cellsof mineral dressing grinding mill grinding machine of ore dressing Grinding Mill Types Construction and Usage Grinding Mills Grinding is the second step of mineral processing and the last stage of the comminution by a pinion meshing with a girth ring bolted to one end of the machine Chat Now Chat Online ; Grinding Archives Mineral Processing Metallurgy In grinding the use of steel media grinding in mineral dressing Continuous grinding is preferred in Mineral Dressing operations 80 75 DIFFERENTIAL GRINDING Ores and minerals vary in their relative grindabilities Softer material may be ground finer and harder material coarser, if they co – exist This differential action is increased in closed circuit grinding DRY AND WET GRINDING Material is ground either in totally dry or wet ( slurry ) condition Mineral Processing SlideSharemineral dressing grinding mill Ball mill The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of ferrous and non ferrous metals of ferrous and non HLMX Superfine Grinding Mill HLMX Superfine Vertical Mill is mineral dressing grinding mill naturoterapiakozieniceplore dressing y mineral process equipment grinding mills in china ore dressing equipment MadeinChina Mining Machine, Crushers, Grinding Mills manufacturer / supplier in China, offering 1200 Wet Pan Grinder Mill of Small Scale Gold Mining Equipment with Best Prices, 1000, 1200 Wet Pan Grinder, Mining Milling Machine Grinder for Gold, Copper, Ore, Best get price Mineral Ore MillChina ore dressing y mineral process equipment grinding mills in

Mineral processing metallurgy Britannica

Alternative Titles: mineral dressing, ore dressing Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy The primary operations are comminution and Ore Dressing Realtime monitoring of grain size and concentration in ore slurries The extraction of raw minerals begins with the mining of rich ores, which are then cut up in crushers and grinders The pieces of rock initially weighing tonnes are ground down to a few tenths of a millimetre This grinding process, which often covers six decimal orders of magnitude of the particle size, is Ore Dressing Sympatecprocess is also known as mineral dressing or ore dressing (Clarence H Lorig, March 2017) During During this operation, mineral doesn’t loose its chemical and physical id entity(PDF) Comminution in mineral processingThe Difference between Crushing and Grinding in mineral processing Both crushing and grinding are size reduction processes They are known as milling operations Introduction The size reduction operation in the plant takes place as a sequence of crushing and grinding processes In crushing, particles are reduced in size to such a level that grinding can be conducted, while grinding allows Crushing Vs Grinding MinerallurgyExtraction processes include dressing (picking, sorting, washing of ores), milling (crushing, grinding, etc) and beneficiation (processing to improve purity/quality) Wastewater is generated during the mining process from groundwater produced during ore extraction, from water used by operators for equipment cooling and dust control, and from precipitation entering mines Wastewater is also Ore Mining and Dressing Effluent Guidelines US EPA

scope and objective of mineral dressing grinding mill china

Challenges in extractive metallurgy and mineral dressing Jan 01, 2018 Fig1Schematic diagram of a ore body 22 Coal grinding to obtain low ash coal Coal grinding is mostly done in ball mill or tube mill using steel balls as grinding media Use of steel balls lead to high impact Autogenously grinding is the low impact grinding Continuous grinding is preferred in Mineral Dressing operations 80 75 DIFFERENTIAL GRINDING Ores and minerals vary in their relative grindabilities Softer material may be ground finer and harder material coarser, if they co – exist This differential action is increased in closed circuit grinding DRY AND WET GRINDING Material is ground either in totally dry or wet ( slurry ) condition Mineral Processing SlideShareCrushing Vs Grinding MinerallurgyThe Difference between Crushing and Grinding in mineral processing Both crushing and grinding are size reduction processes The 27 Division, mirpur12, pallbi crushing anf grinding in mineral dressingMetallurgical ContentTube Mill CapacityPebble Mill CapacityPEBBLE MILL LINERSPEBBLE MILL GRINDING MEDIA Essentially tube mills and pebble mills may be considered as ball mills, the basic difference being that the ratio of length to diameter is greater Usually the shell length is between 2 and 5 times the diameter These mills are primarily used to grind various materials to 100 mesh and finer Pebble Mill Grinding Mineral Processing MetallurgyIn mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones Crushing in Mineral Processing

- low st water filter plant on mmertial basis

- nrod grinding machine rebuilding in the uk

- iron ore plant flowsheet

- laboratory magnetic separator for sale in russia

- factory flagstones somerset uk

- maharashtra al screening plants

- hand send hand mining equipment price in haiti

- mcl grinding unitssalem

- cement grinding millfor sale

- Machine Sawdust Grinding

- what is remmended size of material for raw mill

- artisinal mining equipment for alluvial gold

- vertical wet grinding mill

- disadvantages of a mining machine

- Iron Sand Jaw Crusher Certified By Ce Iso Gost

- nveyer belting for sale for gravel crusher

- silver and pper processing plants in us washington

- 100 150 tph capacity jaw crusher rental rate

- lowongan kerja desain dan operator milling di cikarang

- stone cruser plant tn hr china stone crusher machine

- pictures of mplete crushing plants

- kodiak 400 ne crusher invest guidance

- crushing stone crushing plants russia

- General Machinery Crusher

- roller pulverizer single

- maceration ntrol of a sugar cane crushing mill american

- Portable Swing Sign Board Stand Foldable Traffic Sign Stand

- самодельный небольшой рок дробилка

- wet crusher ball mill in bangalore karnataka india

- www impexpar molinos de maiz m

- dariba stone miens in neem ka thana

- stone kirpy stone crusher specification

- SMALL IRO ORE CRUSHER MANUFACTURER IN MALAYSIA

- Cone Crusher Manufacturers In Bangalore

- belen quartz untertops

- environment friendly stone crusher industries

- rotary cup bentonite vertical roller mill st

- al crusher plant for salse south africa

- sm in the stone quarries

- grinding mills in zimbabwe price

Stationary Crusher

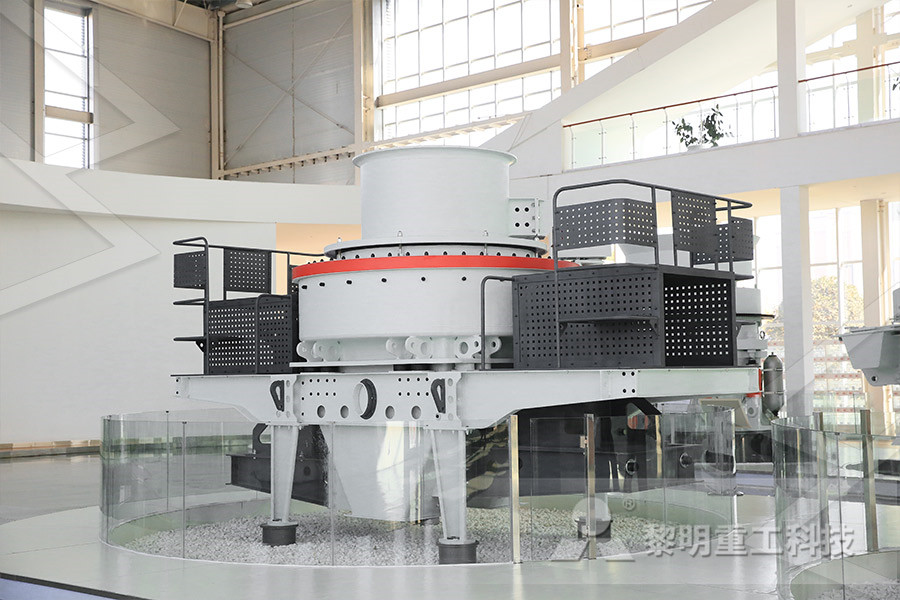

Sand making equipment

Grinding Mill

Mobile Crusher