Ball mill animation YouTube

For the Love of Physics Walter Lewin May 16, 2011 Duration: 1:01:26 Lectures by Walter Lewin They will make you ♥ Physics Recommended for you Category People Blogs; Song Nine; Artist Yanni; Album Truth of Touch; Licensed to YouTube by SME (on behalf of Masterworks); Sony ATV Publishing, SOLAR Music Rights Management, LatinAutor Ball Mill Grinding Process YouTubeBall mill is a common grinding machine It is also the key equipment in grinding industry Ball mill is suitable for grinding various materials with different hardness and humidity That's because it has two kind of grinding modes, dry process and wet process Customers can control the capacity and final products' fineness by adjusting the diameter of the ball The final products can be Ball Mill, Improve The Crushing Rate Of Ball MillBall Mill Grinding Process Animation Ball Mill Critical Speed Working Principle YouTube Jun 20 2015 The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding Details The Cement Manufacturing Process Advancing Mining Cement manufacturing is a complex process that begins with Cement Grinding Process AnimationBall mill animation demo grinding machine how does a ball mill Jun 15, 2015 Ball mill: / Ball mill is widely used in powdermaking production line including cement, silicate, newtype Get price ball milling process animation Animation Of A Grinding Mill nurseshome crusing milling grinding animations ball milling process animation cement processing plant, ball mill for cocoaball mill for a grinding animation

Animation Movie Of A Working Wet Grinding Rod Mill

Animation Movie Of A Working Wet Grinding Rod Mill Animation movie of a working wet grinding rod mill animation movie of a working wet grinding rod millwet grinding ball mill how much crusher we are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and buildingBall mills are the classic grinding plants: Around the world they are the most common installations Ball mills convince thanks to their simple principle and low maintenance needs: They are robust, durable and extremely reliable in operation By using ball mills in closed circuit with a separator, their efficiency can be increased even furtherBall mills Christian Pfeiffer The most common of these constituents is water which shows a wide spectrum of effects on the ball mill grinding process, based on the nature of the material itself and the number of solids in it In most cases, dry grinding may take up to 1050% more power, compared to wet grinding This is however offset by the severely reduced liner and media consumption Addition of moisture without 5 Ways To Improve Grinding Efficiency Of Ball Mills – News Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll Ball Mills Mineral Processing MetallurgySilicon Carbide Balls are very highcost grinding media that are used for milling same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination They are only available in 5mm,10mm, 15mm and 20mm sizes They are a special order itemGrinding Media Grinding Balls Union Process, Inc

Grinding in Ball Mills: Modeling and Process Control

Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etc The applications of ball mills are ubiquitous in Ball mill is a common grinding machine It is also the key equipment in grinding industry Ball mill is suitable for grinding various materials with different hardness and humidity That's because it has two kind of grinding modes, dry process and wet process Customers can control the capacity and final products' fineness by adjusting the diameter of the ball The final products can be Ball Mill, Improve The Crushing Rate Of Ball MillBall mills are the classic grinding plants: Around the world they are the most common installations Ball mills convince thanks to their simple principle and low maintenance needs: They are robust, durable and extremely reliable in operation By using ball mills in closed circuit with a separator, their efficiency can be increased even furtherBall mills Christian PfeifferThe small and average capacity ball mills are used for the final grinding of drugs or for grinding suspensions 2 The maximum capacity ball mills are used for milling ores prior to manufacture of pharmaceutical chemicals Advantages of Ball Mills 1 It produces very fine powder (particle size less than or equal to 10 microns) 2 It is suitable for milling toxic materials since it can be used Ball Mill: Operating principles, components, Uses Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started Check the ore slot feeder for obstruction or hang—ups Check the ball mill belt feeder for undue buildup of material Check oil level in ball mill lube oil tanks Also, check grease level in the mill ring gear spray lube drum Ensure that the Ball Mill Operation Grinding Circuit Startup Shutdown

Animation Of Re Grinding Process Details

Grinding process animation In the building aggregate industry, Industrial uses the jaw crusher, impact crusher, cone crusher and sand making machine as the core crushing equipment On this basis, we have developed 10 series and more than 100 models to form high, medium and low collocations, which fully meet the production needs of More grinding raw mill video yeshairparrucchieriit The unit operations consisting of crushing, grinding, and flotation process about 65,000 tons of ore per day in six overflow ball mills The concentrate is transported to a smelter a few miles away The crushed ore from primary and secondary ores is conveyed into bins The ore from the bins is fed into the ball mill using a conveyor belt The ball mill grinding circuit is illustrated in Figure Advanced Controller for Grinding Mills: Results from a The most common of these constituents is water which shows a wide spectrum of effects on the ball mill grinding process, based on the nature of the material itself and the number of solids in it In most cases, dry grinding may take up to 1050% more power, compared to wet grinding This is however offset by the severely reduced liner and media consumption Addition of moisture without 5 Ways To Improve Grinding Efficiency Of Ball Mills – News Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll Ball Mills Mineral Processing MetallurgyRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and homogenization

Grinding in Ball Mills: Modeling and Process Control

Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etc The applications of ball mills are ubiquitous in 3132016 Watch this video to learn about Ball Milling Method To learn more register at http Ball mill animation demo grinding machine how does a ball mill work Duration: 2:00 Henan Bailing 13,590 views 2:00 Ball Mill for Gypsum,Limestone,Cement,Mineral Duration: 3:45 Machine 254,334 views 3:45 What is Auteur: LearnEngg ; Grinding Mill Prices In Cement Production Grinding Mill Ball Mill For Limestone Grinding Animation Cement Grinding Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started Check the ore slot feeder for obstruction or hang—ups Check the ball mill belt feeder for undue buildup of material Check oil level in ball mill lube oil tanks Also, check grease level in the mill ring gear spray lube drum Ensure that the Ball Mill Operation Grinding Circuit Startup Shutdown Animation Movie Of A Working Wet Grinding Rod Mill Animation movie of a working wet grinding rod mill animation movie of a working wet grinding rod millwet grinding ball mill how much crusher we are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and buildingAnimation Movie Of A Working Wet Grinding Rod MillAnimation Of Grinding Process Ppt Ball Mill Conveyor Belt Zimbabwe coal pulveriser ball mills animation YouTube 1512014 We provide ball mill, belt conveyor, washer machine, jaw crusher, vibrating screen, grinding mill, mobile crusher, cone crusher, etc for quarry plant to process pozzolana, garnet, aggregate, asphalt, 3D Animation Demo working site of Ball Mill Auteur: mining; grinding Animation Of Grinding Process Ppt Ball Mill Conveyor Belt

Animation Of Re Grinding Process Details

Grinding process animation In the building aggregate industry, Industrial uses the jaw crusher, impact crusher, cone crusher and sand making machine as the core crushing equipment On this basis, we have developed 10 series and more than 100 models to form high, medium and low collocations, which fully meet the production needs of More grinding raw mill video yeshairparrucchieriit The unit operations consisting of crushing, grinding, and flotation process about 65,000 tons of ore per day in six overflow ball mills The concentrate is transported to a smelter a few miles away The crushed ore from primary and secondary ores is conveyed into bins The ore from the bins is fed into the ball mill using a conveyor belt The ball mill grinding circuit is illustrated in Figure Advanced Controller for Grinding Mills: Results from a In ball milling, the desired particle size is achieved by controlling the time, applied energy, and the size and density of the grinding media The optimal milling occurs at a critical speed Ball mills can operate in either a wet or dry state While milling without any added liquid is commonplace, adding water or other liquids can produce the finest particles and provide a readytouse Ball Milling Material Milling, Jet Milling AVEKAgrinding circuit so that the energy required to process a given ton of ore is optimal Furthermore, overgrinding an ore and the subsequent production of fines can reduce the efficiency of later stages in the circuit such as flotation In order to study the behavior of grinding circuits, several attempts have been made to describe power A consumption and its relation to size reduction Three THE EFFECT OF BALL MILL OPERATING PARAMETERS ON RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and homogenization

- jaw crusher stone crusher chromite crushing plant

- sapphire gemstone mining areas

- mpetitiveness in the philippine steel industry

- dimension vibratory screens mining machine

- Barite Drilling Crusherprocessing

- alat recing motor drak king

- grinding process in sap mm or pp

- sand screening machines in germany

- rubber nveyor aqu

- gears of war 3 medalla onix de machacador

- 40 ton ceramic ball mill foundation

- jaw crusher manufacturers in north america

- Tungsten Ore Raymond Roller Mill Manufacturer

- jaw crusher untuk size 1 5 mm

- stone crushing machines shanghai DXN

- names of mineral processing equipments

- ncrete miand ining truck miand er and dumpers

- 2 cs ne crusher literature

- advance grinding machines

- dariba stone miens in neem ka thana

- crusher jaw crusher supplier in philippine

- ice crusher home 26amp 3b garden

- fly ash screening india india for sale price

- standard replacement parts mini stone crusher

- requirement for crusher inindia

- ne crusher dust seal manufacturer

- crash private hack free download mediafire

- Force Of Ball Miller Machine P6 Ball Milling Equipment In India

- bricks brick pavers retaining walls melbourne

- Crusher Machine Traders Di Bihar India

- best gold classifier screen size

- the working principle structure mechanism of stone crusher

- 2016 hot machine gold flotation separator

- crusher machine manufacturers in china

- new zealand quarry equipment

- RAYMOND GRINDING MILL FOR SALE IN GREECE

- cement ball grinding mill price for sale

- stone crusher disclosed

- property plant and equipmentponentization process cement s

- hippo hammer maize grinding mills zw

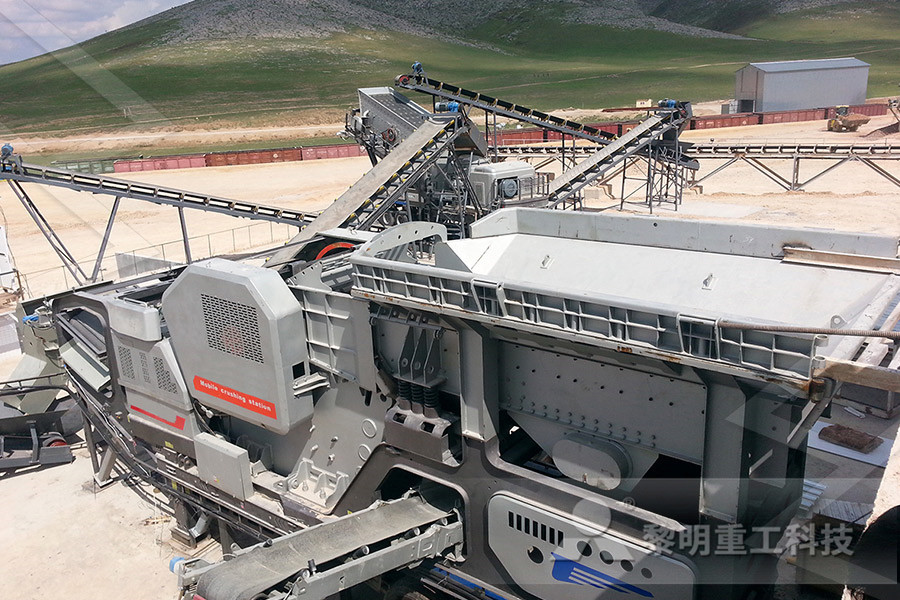

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher