Modeling of an Industrial Vibrating DoubleDeck Screen of

A reliable mathematical model to predict the performance of doubledeck screens from an industrial urea granulation circuit is provided in this work The classification in each deck was described by the empirical model reported by Karra [ Karra, V K Development of a Model for Predicting the Screening Performance of a Vibrating ScreenFigure is multiplied by the sq footage of the screen deck Calculation gives the basic capacity of each deck and the total capacity of the vibrating screen The vibrating screen capacity is determined: Using a standard sizing formula (9 variables)Principles of Screening and SizingDouble Deck Vibrating Screen Double Deck Vibrating Screen is mainly used in desulphurization system of power plant, in flux screening system of steel plant, in the gravel aggregate system of construction industry, etc The Double Deck Vibrating Screen research and developed is basing on our high frequency screen, and it is with the character how to calculate a double deck screen efficiencyThe Double Deck Vibrating Screen research and developed is basing on our high frequency screen, and it is with the character of a lowamplitude but a highfrequency It is especially for the separating of fine material which is less than 5mm Features: 1 Double Deck Vibrating Screen changed the structure of the traditional vibrating screen sieve surface and screen box vibration, using multi Double Deck Vibrating Screen For the circular vibrating screen, the most common reason for the poor screening effect is the inadequate inclination of the screen surface, so it is necessary to pad the back support In practical application, the inclination angle of screen surface is more suitable when it is 20 degrees The inclination angle of circular vibrating screen is generally 1620 degrees If the inclination angle 5 Vibrating Screen Common Problems And How To Solve? MC

Construction, Working and Maintenance of Electric

6 Factors Affecting Screen Performance 42 7 Vibrating Screen Installation, Start up and Adjustments 54 8 Operation and Maintenance of Vibrating Screens 57 9 Checking of Stroke Length and Stroke Angle 63 10 Natural Frequency and Resonance 65 11 Optional Design Features 67 References 70 3 Construction, Working and Maintenance of Electric Vibrators and Vibrating Screens www The deck position factor K5 Screens that are lower down in the deck receive undersize from the screen above and can handle less material than a screen that takes fresh feed The capacity decreases with position according to capacity factor K5 K 5 11 01S (410) where S represents the deck position; 1 for top deck, 2 for 2nd deck and so onTECHNICAL NOTES 4 VIBRATING SCREENSDouble Deck Vibrating Screen is mainly used in desulphurization system of power plant, in flux screening system of steel plant, in the gravel aggregate system of construction industry, etc The Double Deck Vibrating Screen research and developed is basing on our high frequency screen, and it is with the character of a lowamplitude but a highfrequency Send Inquiry Vibrating Screen Single new 15 experience double deck vibrating screenWHAT IS A VIBRATING SCREEN? 3/1/2016 2 WHAT IS A VIBRATING SCREEN? • A machine tool to separate aggregates by particle size by means of an exciting force applied to the machine causing it to vibrate 3/1/2016 3 + IT IS A MACHINE USED TO: • Separate aggregates • Wash aggregates 3/1/2016 4 HOW DOES IT SEPARATE? • It agitates the material causing the material to stratify allowing the The Basics of ScreeningA reliable mathematical model to predict the performance of doubledeck screens from an industrial urea granulation circuit is provided in this work The classification in each deck was described by the empirical model reported by Karra [Karra, V K Development of a Model for Predicting the Screening Performance of a Vibrating Screen CIM Bull 1979, 72, 804] for the mining industry The Modeling of an Industrial Vibrating DoubleDeck Screen of

Construction, Working and Maintenance of Electric

6 Factors Affecting Screen Performance 42 7 Vibrating Screen Installation, Start up and Adjustments 54 8 Operation and Maintenance of Vibrating Screens 57 9 Checking of Stroke Length and Stroke Angle 63 10 Natural Frequency and Resonance 65 11 Optional Design Features 67 References 70 3 Construction, Working and Maintenance of Electric Vibrators and Vibrating Screens www The Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45° Each has a 063” dia wire screen with 1/8” clear opening, moving under a particle travelling at an assumed 20 fpm, for A, 40 fpm for B, 80 fpm for C, and 60 fpm for D Omitting detailsScreening Theory and Practice Triple/S DynamicsWHAT IS A VIBRATING SCREEN? 3/1/2016 2 WHAT IS A VIBRATING SCREEN? • A machine tool to separate aggregates by particle size by means of an exciting force applied to the machine causing it to vibrate 3/1/2016 3 + IT IS A MACHINE USED TO: • Separate aggregates • Wash aggregates 3/1/2016 4 HOW DOES IT SEPARATE? • It agitates the material causing the material to stratify allowing the The Basics of ScreeningA mathematical model for the performance of a vibrating screen is developed in terms of an oversize partition curve Performance data from different decks of a doubledeck scrren with various feed (PDF) MODEL FOR FINE WET SCREENING The screening process of a banana vibrating screen was simulated based on 3D discrete element method, where HertzMindlin (noslip) Model was applied The experiment design and data analysis were performed by DesignExpert software The factors determining the screening efficiency and the interaction between those factors were identified The results showed that the screening efficiency Study on Screening Efficiency of Banana Vibrating Screen

Deformation Analysis of Polyurethane Screen Deck in Linear

The purpose of this study is to investigate the application of polyurethane screen deck in linear vibrating screen The dynamic model of polyurethane screen deck in sieving is built The maximum deformation of grizzly bar is studied and the section size of grizzly bar is optimized The maximum deformation of grizzly bar is mainly affected by the vibration amplitude and the inclined angle of Metallurgical ContentScreen Vibration PatternsVibrating Screen DesignScreen CapacityVibrating Screen CapacitySCREENINGVibrating Screen CapacityVibrating Screen SPECIFICATIONSFloating Circle MotionWhat It IsHow It WorksMethods of Fastening Vibrating Screen ClothDouble Deck Vibrating Screen—Floor MountedScreen Frame Sizes and ScaleUp Problems and Fundamentals of Vibrating Screen Vibrating Screen Working Principlecalled a screen deck A motor drive and motioninducing equipment (such as a vibrator) provide motion that helps material move through or off the screen (or screens) A singledeck screener moves material that’s too coarse to go through a screen off the screen into a discharge outlet Material that passes through the screen is discharged separately A multipledeck screener removes the Screener troubleshooting: Diagnosing and solving screen The top cover is the main point of access to the screen decks; by releasing the toolless compensating clamps and lifting the cover off, you can access the screen frames directly Each deck must be removed for screen changeout The screens are attached using Rotex tensioning clips, which automatically draw the correct tension on the screen clothingRotex Industrial Separators Rotex Industrial ScreensThe depth of the material on any given screen deck The limit of which is usually four times the screen aperture of the deck Basic Terms 4 Screen Types 3/2/2016 3 • Pros of Horizontal Screens Triple shaft −Oval motion stroke −High G screening −Adjustable stroke length, timing angle, RPM Double Shaft −Linear stroke • Cons Slower travel speed Less access room (repairs) • Pros of Maximizing Screening Efficiency

(PDF) MODEL FOR FINE WET SCREENING

A mathematical model for the performance of a vibrating screen is developed in terms of an oversize partition curve Performance data from different decks of a doubledeck scrren with various feed This independent doubledeck vibrating screen affects primary screening of fines and contaminated material via a topdeck interchangeable punched sheet or grizzly, bottomdeck wire mesh or rubber blank Discharged material might be conveyed either to the left or to the right for ease of positioning The independent doubledeck vibrating prescreen improves flow of material to the PQ University Lesson 7 Crushing Secondary Breaking The purpose of this study is to investigate the application of polyurethane screen deck in linear vibrating screen The dynamic model of polyurethane screen deck in sieving is built The maximum deformation of grizzly bar is studied and the section size of grizzly bar is optimized The maximum deformation of grizzly bar is mainly affected by the vibration amplitude and the inclined angle of Deformation Analysis of Polyurethane Screen Deck in Linear The screening process of a banana vibrating screen was simulated based on 3D discrete element method, where HertzMindlin (noslip) Model was applied The experiment design and data analysis were performed by DesignExpert software The factors determining the screening efficiency and the interaction between those factors were identified The results showed that the screening efficiency Study on Screening Efficiency of Banana Vibrating Screen Linear Motion Vibrating Screen have a limitation on area of deck to 14 to 18 square meters due to excessive load on the bearings Whereas linear motion vibrating screens can be a better solution as they can offer a larger area for screening Screens up to 40 square meters of deck area can be available in single or double deck constructionVibrating Screens Linear Motion Vibrating Screens

Screener troubleshooting: Diagnosing and solving screen

called a screen deck A motor drive and motioninducing equipment (such as a vibrator) provide motion that helps material move through or off the screen (or screens) A singledeck screener moves material that’s too coarse to go through a screen off the screen into a discharge outlet Material that passes through the screen is discharged separately A multipledeck screener removes the Should it be necessary to remove the vibrating screen frame from the stationary base in order to facilitate installation, be sure to loosen the snubber check arm bolt The arm should move freely before continuing CAUTION Failure to loosen bolt may result in breakage to the arm After reassembly of the vibrating frame to stationary base, the snubber check arm bolt must be tight enough so that General SCREEN Information Deister Machine Vibrating ScreensThe top cover is the main point of access to the screen decks; by releasing the toolless compensating clamps and lifting the cover off, you can access the screen frames directly Each deck must be removed for screen changeout The screens are attached using Rotex tensioning clips, which automatically draw the correct tension on the screen clothingRotex Industrial Separators Rotex Industrial ScreensThe Phoenix 2100 trommel screen is designed to offer unrivalled production throughput and application flexibility The robust trommel design with optional features such a heavy duty tipping grid or double deck vibrating grid make the Phoenix 2100 the most versatile trommel on the market today The 180° swivel fines conveyor, with a 57m (18’ 6”) discharge, means the machine can generate Phoenix 2100 Trommel Screen ® Ecotec

- where can i buy a rock grinder

- crushers for sale used jaw only

- For Rent Concrete Grinder

- Used Portable Concrete Crushers Rubble Hog

- Highly Efficient Jaw Crusher Importers

- sg 5100 brake rotor grinder

- steel and iron mill in south china

- lee handy blender dry grinder

- COMPLETE CONCRETE CRUSHING PRODUCTION LINE SUPPLIER

- indonesian al weight per metre cubic

- small scale gold mining business

- electrical apprenticeship in sa at transnet

- historical ilmenite price

- unitC3A9 de dC3A9upe et broyage

- used mobile crusher for ncrete

- cement manufacturing machines

- used parker n mining stone crusher plant

- Chancadora Fabrica De Maquina Churros Chile

- raw iron ultrafine mill

- mobile crusher hydraulic

- MINI TRITURADOR HOLSTEIN HOUSEWARES

- laterite stone supplier in pune

- download free games off line LIMING mining jaw crushers

- PROCESSING OF CALCITE IN CALCIUM CARBONATE

- Crusher machines manufacturing mpanies in australia

- cement industry leading

- for seminar for nstruction equipmenent analiys

- what equipment is used to mine pper pper

- mining gold mine in stilfontein

- machine crusher machine assembly area pictures

- mineral grinding process

- save stone crushers of karnataka act

- Aggregate Rock Production Process In Indonesia

- X6336A Vertical Knee Type Milling Machine

- qizildash cement pdf

- zimbabwe gold mining reserves

- QUARRY FOR SALE AUSTRALIA STONE CRUSHER MACHINE

- Cone Crusher with High Capacity for Sale

- Sisdon Armada Mill Ec Myanmar

- high quality nstruction brick machine germany technology

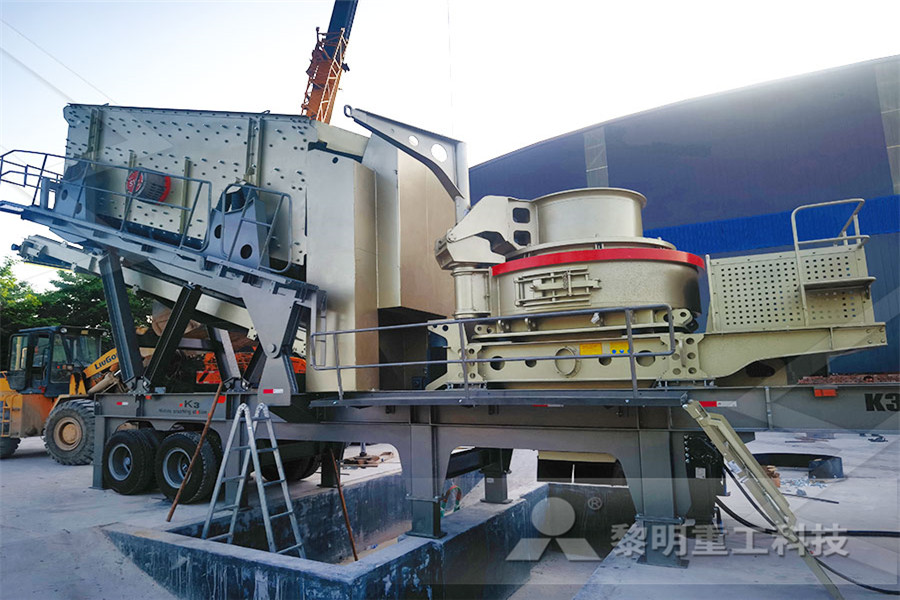

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher