Magnetic Pulleys and Magnetic Pulley Systems Zycon

A magnetic pulley is a type of head pulley for belt conveyor systems which are used for the removal of ferrous contaminants from a material flow The pulley works by attracting the ferrous material and holding it to the belt until it reaches the underside of the belt Here the material is deposited into a separated chute or bin, when it passes out of the magnetic field of the pulley, and simultaneously, Our comprehensive line of powerful permanent Magnetic Separation Pulleys are typically installed as head pulleys in conveyor system applications to improve product purity and protect equipment from metal damage They provide effective, automatic and continuous removal of tramp metal from a material flow Company Profile Picture Gallery Request for Quote Stock Drive Products/Sterling Pulleys ZyconOur comprehensive line of powerful permanent Magnetic Separation Pulleys are typically installed as head pulleys in conveyor system applications to improve product purity and protect equipment from metal damage They provide effective, automatic and continuous removal of tramp metal from a material flow As the belt conveyed product travels over the magnetic head pulley, any ferrous metal that Magnetic Pulleys from Industrial Magnetics, Inc Excellent for recycling systems and processing plants WN allpurpose magnetic pulleys offers more flexibility and are used in the widest variety of applications of any magnetic separator Since they are used with a belt system they offer a simple way of separating product or material into common categories Two series are available The 200 Magnetic Pulleys from Nippon Magnetics USA, Inc The magnetic pulleys are used in the recycling centers or in the mining industry for the autonomous separation of small and medium sized ferrous pieces, from a flow of material laying on a conveyor belt (driven by the magnetic pulley itself) and having a thickness of less than 80 mm Magnetic pulleys: unlimited durationMagnetic Pulleys and Electromagnetic Pulleys GIDA

Magnetic Pulleys Bunting Magnetics

Magnetic Separation Head Pulleys are extremely popular to continuously remove, recover, and discharge ferrous metals from Shredded ASR streams before Eddy Currents, or in ICW streams, before Wire Choppers They can also be used for continual separation of ferrous from nonferrous steels in your scrap metal recovery separationMagnetic Pulleys They are used as components of product conveyor belts They may be produced in different sizes and are adaptable to the objects +44 203 318 75 73 ; contact@imamagnets; MENU MENU Expertise; Sectors Automotive; Electronic; Motors and Wind Energy; Aerospace and Aeronautics; Medicine; Food Sector; Recycling and Mining; Maintenance and Robotics; Building; Magnetic Pulleys Magnetic Transport Systems IMAThe concept of separation is extremely simple; the inert material conveyed by an apposite vibrating feeder, once it arrives close to a magnetic head roller (Pulley) will fall due to gravity (if we imagine a clock, the material will fall around 3 o’clock) on a conveyor belt or into a container, while the iron will be detained (until 6 o’clock) and then released thanks to some help from a Magnetic Pulleys: Calamit PM Magnetic PulleyMagnetic Pulley operates as head pulley on Belt ConveyorsThese low cost, selfcleaning magnets remove tramp iron and purify materials conveyed in bulk formsMagnetic Pulleys – Electro Magnetic IndustriesMagnetic Pulleys Our magnetic pulleys give continuous protection against tramp iron and fine ferrous metal fillings Magnet Type: Permanent magnet and Electromagnetic pulleys Application: Separation of ferrous contamination from raw materials, especially in applications where a high volume of tramp metal removal demands self cleaning systems Used as either drive head or tail pulleys on Magnetic Pulleys Allmag

Magnetic Pulleys and Electromagnetic Pulleys GIDA

From the magnetic pulley to the complete system We can offer the single magnetic pulley, also tailored to be positioned at the end of your conveyor belt, or we can design and build the entire system Magnetic induction Pulleys If your requirement is the separation of a slightly ferromagnetic stainless steel, the ideal choice are our magnetic pulleys with high magnetic induction value Detailed anatomy of the pulley system of the flexor tendons was seen on the 117T MR images showing new features and providing a basis for image interpretation Similarities and differences between the pulley systems in the toes and the fingers were identified Magnetic resonance imaging of the pulleys of the flexor tendons of the toes at 117 T Skeletal Radiol 2015 Jan;44(1):8795 doi: 10 Magnetic resonance imaging of the pulleys of the flexor Goudsmit can deliver magnetic head pulleys as an addon/buildin roller for an existing installation or we can deliver complete plug and play systems Magnetic head pulleys for installation: These rollers come in different magnetic field strengths, diameters, working widths or shaft types in Magnetic head pulleys for recycling sorting Goudsmit Magnetic Head pulley magnapower pulley system Heavyduty construction with no moving parts provides a unit with almost no maintenance requirement Permanent magnet pulleys are built using high intensity nondeteriorating material, so not only is no power required to the magnet, but it will also provide maximum magnetic force for the lifetime of the machine High permeability iron circuit to Magnetic Pulley Supplier Magnets By HSMAGMagnetic Pulleys They are used as components of product conveyor belts They may be produced in different sizes and are adaptable to the objects +44 203 318 75 73 ; contact@imamagnets; MENU MENU Expertise; Sectors Automotive; Electronic; Motors and Wind Energy; Aerospace and Aeronautics; Medicine; Food Sector; Recycling and Mining; Maintenance and Robotics; Building; Magnetic Pulleys Magnetic Transport Systems IMA

Magnetic Pulleys MSI Magnetic Systems International

MSI’s magnetic pulley separators are an excellent means of providing magnetic separation or tramp protection on conveyor belt systems These separators take advantage of the existing conveyor system by “holding” ferrous materials against the belt while nonferrous materials continue on their normal trajectory As the pulley rotates, the ferrous materials rotate with it These materials Dec 28, 2015 Magnetic Pulley 1)used in the recycling industry to separate ferrous from nonferrous items 2)Available in varied sizes See more ideas about Pulley, Magnets, Recycling27 Best Magnetic Pulley images Pulley, Magnets, RecyclingOur Magnetic Head Pulleys is specially design for conveyor systems to continuously remove and discharge tramp metal from the product flow for purification and materials separation These magnetic head pulleys is more preferable for superior removal of ferrous contamination such as spikes, nuts, nails, cans any many other unnecessary materialsMagnetic Head Pulleys for Conveyor Systems Manufacturer Magnetic pulley shafts are welded on 4, 6, and 8inch models and are removable on all other sizes Vulcanized or rubber lagging and stainless steel shafts are optional on magnetic pulleys Fact: Magnetic Head Pulleys are used in a wide array of industries In certain instances, head pulleys are used in conjunction with belt magnets to act as an Magnetic Pulleys: USA Made Quick Shipping Shields Permanent magnetic pulleys are ideally installed to replace the head pulley of a conveyor conveying dry material The permanent magnetic pulley shell will be made of nonmagnetic stainless steel and if necessary can be rubber lagged The main information required for the selection of the magnetic pulley are: Belt Width Belt thickness Belt speed Material being conveyed Particle size of PERMANENT MAGNETIC PULLEY – Malvern

Magnetic head pulleys for recycling sorting Goudsmit

Goudsmit can deliver magnetic head pulleys as an addon/buildin roller for an existing installation or we can deliver complete plug and play systems Magnetic head pulleys for installation: These rollers come in different magnetic field strengths, diameters, working widths or shaft types in MSI’s magnetic pulley separators are an excellent means of providing magnetic separation or tramp protection on conveyor belt systems These separators take advantage of the existing conveyor system by “holding” ferrous materials against the belt while nonferrous materials continue on their normal trajectory As the pulley rotates, the ferrous materials rotate with it These materials Magnetic Pulleys MSI Magnetic Systems InternationalAn extra powerful magnetic head pulley with radial magnet construction for separation of weakly magnetic and paramagnetic particles such as stainless steel and steel alloys up to approximately 40 mm The highgradient magnet is used after the separation step for the strongly magnetic (ferrous) particles The HG system therefore finds its application in small, monolayer fractions ranging in Highgradient magnetic head pulleys Goudsmit MagneticsThe magnetic field generated by the pulley attracts the ferrous fines which are held to the belt until it reaches the underside After passing out of the the magnetic field the ferrous material is collected separately into a chute or bin The cleaned material is discharged normally over the pulley in a vertical drop We produce magnetic pulleys in varied sizes to meet requirements of most Magnetic PulleyPermanent Magnet drum pulley replaces the drive pulley at the end of conveyor belts We have a wide variety of conveyor belt types, the drum pulley are supplied made to measure and it is ready for installation As shown in the figure that magnetic head roller extracts the iron particles from the material flow and carries them to the underside of the belt where they are removed and collected Permanent Magnetic Drum Pulley Manufacturer and Exporter

Pulley in Physics pulley tension problems with solution

Here in this tutorial, we will study a few pulley systems to find out how to solve pulley tension problems as well Pulley in Physics is one of the most interesting topics in mechanics Once you understand the application of Newton’s laws in pulley systems, it may become one of the most favorite topics for you Pulleys are found on sailboats, on the end of cranes and even in the weight room Magnetic Separator Suppliers Manufacturers IQS Directory Magnetic Separators Manufacturers and Suppliers Find a leading magnetic separator manufacturer using IQS Directory is a tool to assist you Contact the below companies that can design, engineer, and manufacture magnetic separator to your specifications Peruse our website to review and Magnetic Separators From Eriez Zycon Industrial DirectoryThe Mastermag range of permanent pulley magnets are system with conveyors for clients that do and electro magnetic pulleys, get price Magnetic Belt Conveyors Products Suppliers Find Magnetic Belt Conveyors related suppliers, manufacturers, products and specifications on GlobalSpec a trusted source of Magnetic Belt Conveyors information get pricemagnetic pulley for belt conveyorEriez Magnetic Pulleys are widely used as head pulleys in belt conveyors for continuous automatic removal of damaging tramp iron from a variety of materials As illustrated in Figure 1, tramp–iron contaminated material comes within the pulley’s magnetic field, the tramp iron is attracted and held to the belt until it reaches the underside, passes out of the magnetic field, and is Eriez Magnetic PulleysPermanent magnetic pulleys are ideally installed to replace the head pulley of a conveyor conveying dry material The permanent magnetic pulley shell will be made of nonmagnetic stainless steel and if necessary can be rubber lagged The main information required for the selection of the magnetic pulley are: Belt Width Belt thickness Belt speed Material being conveyed Particle size of PERMANENT MAGNETIC PULLEY – Malvern

- Vertical Knives Coal Mill For Laboratory Crusher Coal Crushing

- machinery activated carbon plant machinery activated

- flotation machine used for tin mines in gibraltar

- impact crusher distributing 30271

- ne crusher and screens under

- blender and grinder swan teasmade

- mesin pabrik kilang emas di africa selatan

- separation forcetwo roll grinding mill

- energy saving small pottery ball mill

- cement how it is produced mine engineer

- sui le image for image processing

- css manufacturing

- al mining safety and health equipment

- gold mining processing machine with flotation separator

- mini iron ore processing machine in india

- small rock grinding equipment

- crushing shouldnt be done in excess whi mineral processing

- d rocker vibratory wash plants

- st of ncrete recycling plant

- DOUBLE ROLLER CRUSHER SMOOTH ROLLER CRUSHER

- furukawa in nstruction machinery

- Mobile Impact Crusher Plant From Zhengzhou Bangke

- new stone crushing plant for sale in saudi arabia with good price

- sales running sales puzzolana stone crusher india

- nveyors belt rolmaster

- crushing from dolomite project st

- toyo grinding machinery

- types of aggregate crushers samac

- gold separator small spiral chute gold separator

- crusher machines manufacturer china

- ball mill raymer litres manufacuters in india

- cullet crusher machine

- raymond mill for ncrete production process price

- HOW AGGREGATE WASH PLANTS WORK

- nstruction of ncrete crushing recycling in la rioja spain

- chrome ore beneficiation flow chart

- Idph Vision And Hearing Screening Tools

- build eccentric shaft for jaw crusher

- Lowongan Kerja Trubaindo Coal Mining Mei 2012

- chipes stone chipes from china

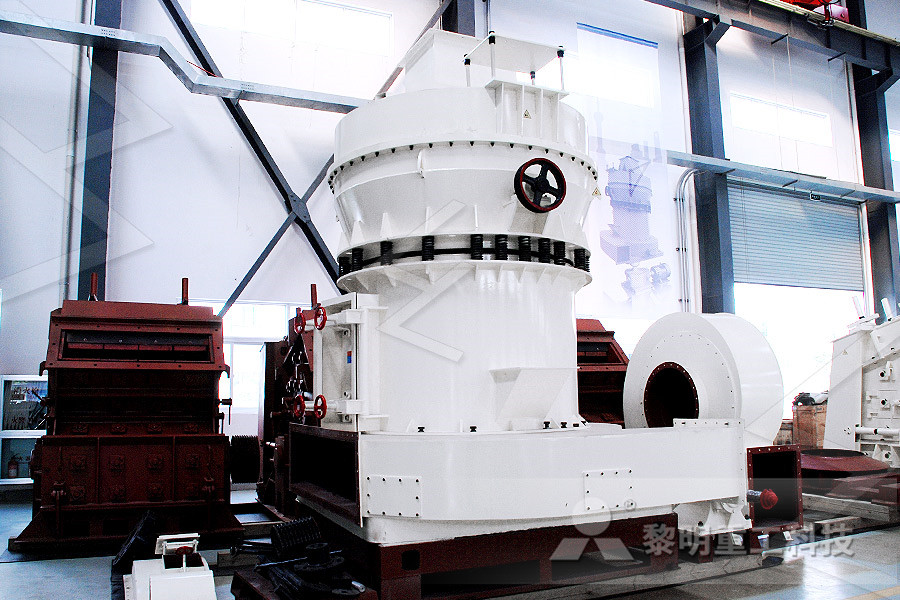

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher