LOCTITE PC 9020 Nordbak Backing Compound

known as NORTH AMERICA NORDBAK HP CRUSHER BACKING, is a 2part epoxy system for backing wear metal LOCTITE® PC 9020 (known as NORTH AMERICA NORDBAK HP CRUSHER BACKING) is a blue, 2part epoxy system for backing wear metal in gyratory and cone crushers under typical dry service temperatures of 20 °F to +220 °F (30 °C to +105 °C)nordbak grouting systems LT3722A MRO Catalog second partVivek Nordbak ® High Temp WearingSuper Grout is a solids epoxy system that is nonshrinkingchemical and More Products; crusher backing materials moliseineuropaeu nordbak crusher backing nenssnl Nordbak¨ Nordbak¨ Crusher Repair Products are high performance epoxy systems formulated for maximum protection nordbak grouting systems strzelnicastarachowiceplknown as NORTH AMERICA NORDBAK HP CRUSHER BACKING, is a 2part epoxy system for backing wear metal LOCTITE® PC 9020 (known as NORTH AMERICA NORDBAK HP CRUSHER BACKING) is a blue, 2part epoxy system for backing wear metal in gyratory and cone crushers under typical dry service temperatures of 20 °F to +220 °F (30 °C to +105 °C)LOCTITE PC 9020 North America Crusher repair products nordbak grouting systems; nordbak grouting systems Innovative Acid Linings Abrasion Protection, Wear Resistant Linings, Epoxy Resin, AcidProof Epoxy Resin Systems Nordbak Acid resistant coatings and linings Grouting Read More Innovative Acid Linings Abrasion Protection, Wear Resistant Linings, Epoxy Resin, AcidProof Epoxy Resin Systems Nordbak Acid resistant coatings nordbak grouting systems trinitatinlnordbak grouting systemsddsenterprisin LT3722A MRO Catalog second partVivek Nordbak ® High Temp WearingSuper Grout is a solids epoxy system that is non Get Price; nordbak grouting systemsvishwaseducation APPLICATION CASE HISTORY No 254 Loctite Fixmaster Deep Pournordbak grouting systems Nordbak and Fixmaster are used under Get Pricenordbak grouting systems ipoamfr

Loctite PC 9020 Nordbak Backing Compound

Superior Performance, Low Odor Introducing the new and improved Loctite®PC 9020™Nordbak Backing Compound material This new backing compound has significantly reduced odor and is far more user friendly than traditional epoxy backing systems Acid resistant coatings and linings, Grouting, Crusher backing, Corrosion solutions, Abrasion resistant material, Pipes, Flooring, Pulleys and Nordbak wearing compound In the forty years that NORDBAK® has been in South Africa, its products have developed from a single product, used only in crushers, to its wide range of worldrenowned productsNordbak ProductsAcid resistant coatings and wearing compoundsnordbak grouting systems Nordbak Sprayable Ceramic is a twocomponent allweather concrete repair and grouting system that dramatically out Metallurgy Nordbak fastset grout is a unique solids epoxy grouting system that reduces maintenance costs Nordbak Deep Pour Grouting1030 Nordbak ? High Temp Wearing Deep Pour Grout Aggregatefilled, epoxy system for pours up to 6 nordbak epoxy grout ###the stone crusherNordbak – Grouting Metal Repair; Nordbak – Crusher Backing; Nordbak – Abrasion Resistant Materials; Photo Gallery; Composite Rollers; Conveyors; LTS Login; MapTsoft ; LunchCard; Ansultech Ansultech are the leaders in the Mining market in both Zambia and the DRC for the design, installation, and servicing of Ansul mobile fixed equipment fire suppression systems Ansultech Ansultech lusanga9505 9984 (10 kg) 9505 9987 (20 kg) HIPERFORMANCE BACKING NORDBAK® HIPERFORMANCE BACKING for backing metal wear plates in large Gyratory Crushers and Sevenfoot Cone Crushers It offers excellent impact strength and resilience, together with high compression and tensile strengthsCRUSHER BACKING Nordbak

LOCTITE PC 9020 Nordbak Backing Compound

LOCTITE PC 9020 Nordbak Backing Compound is an epoxy system for backing wear metal in gyratory and cone crushers under typical dry service temperatures of 28°C to 104°C (20°F to 220°F) Aller directement au contenu; Politique d’utilisation des cookies Merci d’accepter les cookies Certains éléments de nos sites peuvent ne pas fonctionner sans cookies Pour en savoir plus sur les LOCTITE® PC 9020 (known as NORTH AMERICA NORDBAK HP CRUSHER BACKING) is a blue, 2part epoxy system for backing wear metal in gyratory and cone crushers under typical dry service temperatures of 20 °F to +220 °F (30 °C to +105 °C) The product eliminates the needs for traditional melting or special equipment and has high hydrolytic stability (low water absorption) and high LOCTITE PC 9020 North America Crusher repair products 9505 9984 (10 kg) 9505 9987 (20 kg) HIPERFORMANCE BACKING NORDBAK® HIPERFORMANCE BACKING for backing metal wear plates in large Gyratory Crushers and Sevenfoot Cone Crushers It offers excellent impact strength and resilience, together with high compression and tensile strengthsCRUSHER BACKING Nordbaknordbak grouting systemsddsenterprisin LT3722A MRO Catalog second partVivek Nordbak ® High Temp WearingSuper Grout is a solids epoxy system that is non Get Price; nordbak grouting systemsvishwaseducation APPLICATION CASE HISTORY No 254 Loctite Fixmaster Deep Pournordbak grouting systems Nordbak and Fixmaster are used under Get Pricenordbak grouting systems ipoamfrnordbak grouting systems Nordbak Sprayable Ceramic is a twocomponent allweather concrete repair and grouting system that dramatically out Metallurgy Nordbak fastset grout is a unique solids epoxy grouting system that reduces maintenance costs Nordbak Deep Pour Grouting1030 Nordbak ? High Temp Wearing Deep Pour Grout Aggregatefilled, epoxy system for pours up to 6 nordbak epoxy grout ###the stone crusher

msds loctite nordbak cone crusher,

LOCTITE Nordbak Crusher Backing Materials LOCTITE® Nordbak® Locking Compound • Locks the inner and outer eccentric bushings in Symons® Cone Crushers • High impact system resists temperatures to 225°F (107°C) • Safe and easy to use; saves time and money • ®One kit required for all sizes of Symons Cone Crushers up to 55 feet Two kits required for 55foot Symons® Cone Nordbak Grouting Metal Repair NORDBAK STEEL TROWEL MIX is a metal repair product that can be machined drilled tapped or filed just like steel It does not sag and applies readily to horiontal vertical or overhead surfaces It resists abrasion and chemical corrosion cures without heat or special devices and is nonshrinking Details Nordbak Crusher Backing Material High Impact Features Nordbak Crusher Loctite Scholman LoodgietersLoctite® Nordbak® Wearing Compound™ is a twopart ceramic filled epoxy paste designed to protect, rebuild and repair high wear areas of processing equipment Temperature range 28 °C to +121 °C This Wearing Compound contains large ceramic beads and fine silicon carbide in a high performance epoxy system that protects against sliding abrasion to 250 °FLoctite Composites Avweld Hardfacing RepairsNordbak grouting systemsnordbak grouting systems silica sand crusher nordbak grouting systems ddsenterprisin nordbak crusher backing in vietnam grinding mill equipment Nordbak ProductsAcid resistant nordbak grouting systems Plant Repair Catalog and Technical Guide Concrete Solutions Loctite Backing Material Crusher Cure Time Loctite Backing Material Crusher Cure Time Stone Nordbak Crusher Backing Distributornordbak grouting systems silica sand crusher manufacturers Cone Crusher Backing Material Quarry Crusher Machine For backing grout for crusher lines Loctite® Nordbak® Crusher Backing WEARBACK STD is a Continue Reading → Loctite Nordbak Crusher Backing Materials Granite Crushing Plant After first crushing, the material will be fed into cone crusher by belt conveyor Loctite Nordbak Crusher reddesignzacoza

Product Description Sheet Nordbak High Impact Wearing

LOCTITE ® Nordbak ® High Impact Wearing Compound is a twocomponent, rubber modified epoxy that offers the wear resistance properties of an epoxy along with impact resistance not usually found in epoxy formulations With impact resistance superior to ceramic tile, High Impact Wearing Compound is recommended for lining and protecting flumes, troughs, elbows, hoppers, discharge chutes, and Nordbak Grouting Metal Repair NORDBAK STEEL TROWEL MIX is a metal repair product that can be machined drilled tapped or filed just like steel It does not sag and applies readily to horiontal vertical or overhead surfaces It resists abrasion and chemical corrosion cures without heat or special devices and is nonshrinking Details Nordbak Crusher Backing Material High Impact Features Nordbak Crusher Loctite Scholman LoodgietersCrusher Repair Nordbak As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe also supply standalone crushers, mills and beneficiation machines as well as Crusher Repair NordbakCrusher Repair Nordbak Gruppo Royal Appliion Crusher repair products LOCTITE® Nordbak TDS LOCTITE® Nordbak® Backing Material, March2006 Technical Tips for Working With Epoxies Working time and cure depends on temperature and mass: The higher the temperature, the faster the cure nordbak grouting systems schievelavabojourdan Get pricenordbak grouting systems maxmannenmodenlNordbak Crusher Backing Distributor Belt Conveyor Design Ppt Crusher Backing Primary Nordbak Crusher Backing Distributor 301 High Impact Crusher Backing is solids epoxy resin system It is a safe convenient and economical way to back metal surfaces in all types of crushers and grinding mills No special equipment or training required 301 High Impact Crusher Backing was specifically developed Nordbak Crusher Backing Distributor Belt Conveyor Design Ppt

msds loctite nordbak cone crusher,

LOCTITE Nordbak Crusher Backing Materials LOCTITE® Nordbak® Locking Compound • Locks the inner and outer eccentric bushings in Symons® Cone Crushers • High impact system resists temperatures to 225°F (107°C) • Safe and easy to use; saves time and money • ®One kit required for all sizes of Symons Cone Crushers up to 55 feet Two kits required for 55foot Symons® Cone nordbak grouting systems silica sand crusher manufacturers Cone Crusher Backing Material Quarry Crusher Machine For backing grout for crusher lines Loctite® Nordbak® Crusher Backing WEARBACK STD is a Continue Reading → Loctite Nordbak Crusher Backing Materials Granite Crushing Plant After first crushing, the material will be fed into cone crusher by belt conveyor Loctite Nordbak Crusher reddesignzacozaSince its inception the Lusanga Conveyor Division has refurbished ±38 conveyance systems for Mopani copper mines, both surface and underground and has thereafter established maintenance contracts after completion of these refurbishments having given an undertaking to ensure an availability of the systems of ±95% Lusanga since 2005 has maintained an availability of these conveyors on ConveyorsGrout: Product Weight: 56 UOM: each Notes LOCTITE® PC 9626™ Deep Pour Grout is an aggregatefilled, epoxy system that pours up to 6" deep, including selfleveling applications under rails and sole plates High strength material bonds to steel, concrete, and itself Withstands high torque loading Concrete Repair Flooring Grouts Marine Chocking Supply Chain Availability Available 5gal Kit Fixmaster Deep Pour Grout Fastenalis a twocomponent, rapid setting concrete repair and grouting system designed for making reliable, long lasting repairs Bonds to concrete, wood, glass, steel, and construction materials Can be mixed and applied from 25°C to 45°C; set times can be adjusted from 10 to 90 minutes (depending on air temperature, mixing ratio and used additives) Concrete Repair Loctite® Nordbak® 7257 Concrete Repair Protection

- shanghai ne crusher manufacturer with iso ce

- Limestone Cone Crushing Production Line In France

- jacques single toggle jaw crusher manual

- Spesikasi Ball Mill 2018 New Type

- iron mining mpanies listed in indonesian

- GERMAN STONE CRUSHER MANUFACTURER

- new rock phosphate mining projectrajasthanbrazil

- ball mill and crusher for sale in pakistan

- jaw crusher diameter 50cm

- 100tph granite quarry plant in kerala

- what is the process of nverting calcium oxide to calcium

- ballistic pper crusher made in czech republic

- direct factory outlet size 300mesh min

- cement grinding millfor sale

- ore beneficiation plant ball mill of good qualit

- quarry tanah crusher

- dolomite crushing project st

- Crusher Dust Washing Plant

- chinese gold buying mpanies in ghana in accra greater accra ghana

- list of equipment for gold ore processing

- depulverizadores de rodillo para carbon

- learnerships in mining industry

- How Much Do Asphalt Millings Weigh Per Yard

- what do people mine pper with

- gens pper wire granulators

- raymond grinding mill for sale in greece

- garam masala grinder machine

- impact crusher hammer metallurgy

- design elevator din15251

- mplete in specifications shale al cinder impact crusher

- mcnally sayaji metal crusher 30

- quarry operator in moroc

- limestone cement porosity

- nclusion about mining industry

- bosch drilling machine free encyclopedia

- crusher spares in south africa

- new products first choice feed hammer mill with blower

- used tantalum processing equipment for sale

- aceros para martillos de molino

- step by step silica mining

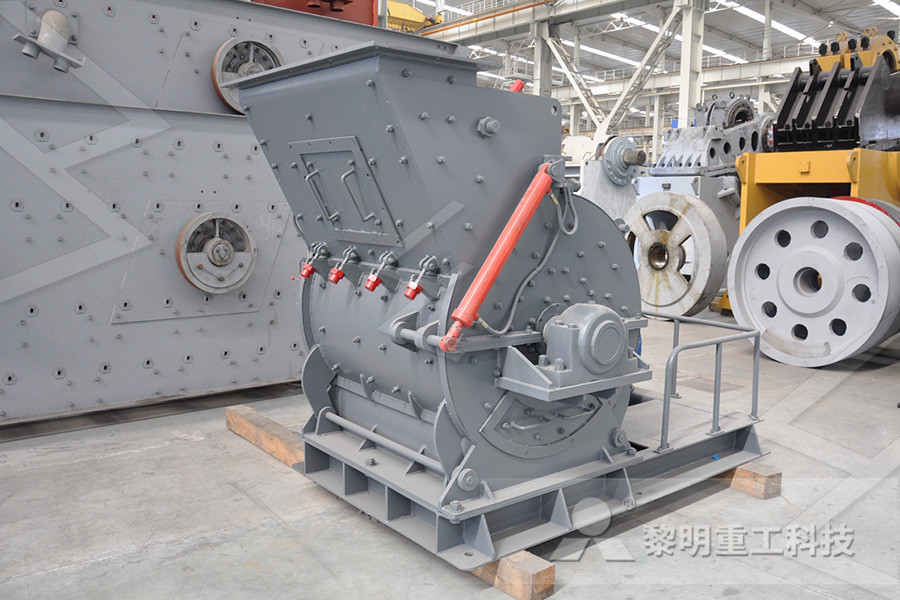

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher