Conveyor Belt Systems and Custom Industrial Conveyors

Axiom manufactures and sells industrial and bulk handling conveyor belt systems for materials management We have standard designs but can custom build according to our customer needs Our conveyor systems are engineered for the demanding industrial applications in which they will be utilized We understand our products will be used for industrial materials Our process begins with For a new conveyor installation having little or no slope, a rope or cable should be attached to a clamp at the belt end In clamping to the end of the belt for pulling it on the conveyor, it is not sufficient to cut a hole through the belt or ears into its corners for tying on a ropeConveyor Belt Installation, Maintenance Troubleshooting If belt conveyor pulleys are adjusted during installation or maintenance, nip point guard (at drive end on end drive unit) must be readjusted Nip point guard (takeup end) is automatically adjusted when takeup pulley is adjusted Nip point guards at both ends of conveyor (center drive) must be readjustedBELT CONVEYORS TECH HANDBOOK21 hours ago Belt conveyor systems for underground mining, tunnelling and construction works are characterised by their high flexibility regarding routing and conveying distance as well as easy and fast installation and dismantling Especially for tunnelling projects, which are temporary by nature, quick installation, removal, and none the less, reusability is of high importance Certainly, one of the most Fast and Flexible – Speed up Planning and Installation The drives can be integrated well into the standard belt conveyors in sizes 20 – 40, 30 – 60 and 40 – 80 (installation height – installation/belt width in mm) Wider conveyors too, such as the 40 – 120 and 40 – 160 versions, are available, as are special solutions based on the same principle, such as ascending conveyorsSystem Installation Belt Conveyor Cabin X Ray

Portable Belt Conveyor Systems Mini Conveyors

These portable conveyor belt systems are the ideal choice for moving loose materials, debris, rock, dirt, cement and more pool installation; firewood conveyor; tight access jobs; difficult terrain jobs; With accessories including hoppers, adjustable leg kits, side extensions to prevent spillage, clamp kits to mechanically lock conveyors together and cantilevers, we can put together a JMS Recently visited a Wastewater Treatment Plant in Nebraska to check on the startup of multiple BioBELT (Belt Conveyor System)s These Belt Conveyors wherJMS at Work Belt Conveyor System Installation at Conveyor belts generally are composed of three main components: 1 Carcass 2 Skims 3 Covers (carry cover and pulley cover) CARCASS The reinforcement usually found on the inside of a conveyor belt is normally referred to as the "carcass" In a sense, the carcass is the heart of the conveyor belt since it must: 1 Provide the tensile strength Conveyor Belt Manual IBT Industrial Solutionspoor installation, arduous operation or inadequate maintenance The high cost of a belt compared to the total cost of a conveyor system makes necessary the adoption of correct steps in installation, operation and maintenance throughout the life of the belt We believe that this manual will assist you in gaining the maximum life from our beltCONVEYOR BELTING INSTALLATION, OPERATION AND Conveyor Installation and Maintenance Manual 600 S Commercial Street Neenah, WI 54956 PH: 8442932816 modularconveyorConveyor Installation and Maintenance Manual

BELT CONVEYORS TECH HANDBOOK

GENERAL INSTALLATION INFORMATION NEVER connect belt conveyors directly to gravity conveyors, machinery or fixtures without using connector brackets pop out roller ALWAYS anchor permanent supports to floor (or mounting surface) Use 3/8” x 21/2” (or longer) wedge anchors for permanent installation in concrete flooring It is the responsibility of the customer and installation These portable conveyor belt systems are the ideal choice for moving loose materials, debris, rock, dirt, cement and more pool installation; firewood conveyor; tight access jobs; difficult terrain jobs; With accessories including hoppers, adjustable leg kits, side extensions to prevent spillage, clamp kits to mechanically lock conveyors together and cantilevers, we can put together a Portable Belt Conveyor Systems Mini Conveyorsconveyor or guards Where system function will be impaired by providing the minimum clearance of 200 meters (6 feet 8 inches) through an emergency exit, alternate passageways should be provided It is permissible to allow passage under conveyors with less than 200 meters (6 feet 8 inches) clearance from the floor for other than emergency exits if a suitable warning indicates low headroom INSTALLATION AND MAINTENANCE MANUAL ROLLER BED BELT Cleated Belt Conveyor Installation If your business regularly moves bulk, lose products and has limited space, you might want to consider adding cleated belt conveyors These conveyors allow you to keep your product separated as it is conveyed up and down inclines and declines At Allstate Conveyor, we have the experts that you need to design and build the perfect cleated belt conveyor system Cleated Belt Conveyors Installation Maintenance Design, installation, and maintenance of manual and automated industrial conveyor belt systems Experienced technicians executing preventative maintenance programs Conveyor machinery and material handling equipment installation and modifications Shutdown repair and support Fabrication capabilities Miscellaneous metals, supply and install, to the construction industry; We are experts in Material Handling Equipment Canada, (MHSC), Conveyor Belt

INSTALLATION AND SERVICE MANUAL FOR CHAIN CONVEYORS, BELT

Safety: Safety precautions for conveyor maintenance 3 Installation: Mechanical and Electrical in form tionbou theInsll he various types of equipment in the conveyor system 4 Preventive Maintenance and Inspection Guide: n eof thmos impo rac sn th v l cost effectiveness of your material handling system is that of preventive maintenance and“FC” Belt Conveyor INSTALLATION OPERATING INSTRUCTION MANUAL Manufactured in the USA by MANUFACTURING COMPANY PO Box 1086, 2000 E Leffel Lane • Springfield, Ohio 45501 Toll Free: 18003347254 (in USA Canada) • Phone: 9373251511 • Fax: 9373221963 sweetmfg I Galvanized Formed Channel Belt Conveyor 09/2010 STANDARD INSTALLATION OPERATING INSTRUCTION MANUALConveyor belts are frequently blamed for belt tracking problems and in most cases this is unjustified The failure cause is usually to be found in the installation itself and may be the result of poorly adjusted pulleys and rollers, incorrect application of belt tracking measures or faulty design It is therefore essential to be fully aware of the basic characteristics of the different belt 3 Basic Conveyor Belt Tracking Rules To Follow Accurate – conveyor belts Content 1 Terminology 2 Unit goods conveying systems 3 Takeup range for loaddependent takeup systems 8 Bulk goods conveying systems 9 Calculation example Unit goods conveying systems 12 Conveyor and power transmission belts made of modern synthetics Worldwide leaders in technology, quality and service Further information on machine design can be found in our Calculation methods – conveyor beltsINCREASING BELT CONVEYOR RELIABILITY THROUGH “VIRTUAL PROTOTYPING” EA “Bud” Viren, Vice President Overland Conveyor Co, Inc 21 Ox Yoke Trail Carlile, WY 827218706 3077563893 3077563231 Fax Viren@overlandconveyor Mark A Alspaugh, President Overland Conveyor Co, Inc 12640 W Cedar Dr Suite D Lakewood, CO 80228 3039737357 3032175208 Fax MineWest Belt Conveyor Reliability

Portable Belt Conveyor Systems Mini Conveyors

These portable conveyor belt systems are the ideal choice for moving loose materials, debris, rock, dirt, cement and more pool installation; firewood conveyor; tight access jobs; difficult terrain jobs; With accessories including hoppers, adjustable leg kits, side extensions to prevent spillage, clamp kits to mechanically lock conveyors together and cantilevers, we can put together a Conveyors Plus Inc develops, sells, installs, and supports the the Sure Align Tracker conveyor alignment system Our products are designed for the mining, oil and gas, and material handling industries The Sure Align Tracker is a proven system which results in immediate increases in safety, productivity and cost savings Discover how our products can reliably address your conveyor belt Conveyors Plus – The Conveyor Belt Alignment SystemConveyor Installation No matter your conveyer installation challenges, you can trust Lovegreen Industrial Services to provide an efficient and costeffective solution Since 1948, companies have trusted Lovegreen conveyors and our millwright installation to get the job done right the first time And all installed conveyors meet or exceed Professional Conveyor System Installation and calibration Design, installation, and maintenance of manual and automated industrial conveyor belt systems Experienced technicians executing preventative maintenance programs Conveyor machinery and material handling equipment installation and modifications Shutdown repair and support Fabrication capabilities Miscellaneous metals, supply and install, to the construction industry; We are experts in Material Handling Equipment Canada, (MHSC), Conveyor Belt A single conveyor can run at close to 100% reliability, but as the number of conveyor increases, the reliability of the conveyor belt system is mostly depend upon its control system The control system has sensing device like zero speed sensing, receiving conveyor position sensing It has also facility for selection to operate conveyor avoiding control system ie manual run mod In some Roller / Industrial Conveyor Belt System Belt Conveyor

INSTRUCTION MANUAL FOR MODEL SBC SLAT BELT CONVEYOR SYSTEM

removal installation of slats 8 311 removal 8 312 installation of slats 9 32 bearings 9 33 chain takeup 10 331 slat belt chain 10 332 drivechain 11 34 detergent feed pump 11 341 replacing detergent pump 12 342 detergent 13 35 gear box 13 36 replacing gear box 13 4 slat belt conveyor parts 14 41 sbcslat belt conveyor parts 14 42 sbcslat belt conveyor Astec Conveyors Limited provides a personal conveyor system installation and commissioning service and does not see their role as simply supplying products on demand We are totally committed to customer service and acknowledge the importance of liaising closely throughout a contract Customers can protect their investment in equipment and materials handling systems with a range of after sales Conveyor System Installation and Commissioning Astec The belt conveyors are made of original item Profiles This allows you to use the entire range of item products in order to integrate the elcom belt conveyors into into your frames We can of course equip the belt conveyors with belt supports ex works For instance, see types A and B in the illustrationsMain elements of belt conveyors – elcom – conveyorsconveyor to have a reliable scale installation That is not to say the hardware isn’t important–it is That’s why we have has worked for years to develop the most reliable belt conveyor scale systems on the market We have pioneered the advances in belt conveyor scale electronics from early and simple analog circuits, through such improvements as zero and span calibration assists Thermo Scientific Belt Conveyor Scale Handbook18 Dust Suppression System and Dust Collection System 185 19 Magaldi Superbelt 204 20 Belt Training / Tracking 206 21 Steep Angle Conveying 223 22 Pipe Conveyor 241 23 Safety 250 24 Trouble Shooting 261 25 Maintenance Tools and Recommendations 267 References 269 3 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants Construction and Maintenance of Belt Conveyors for Coal

- alumina grinding plant refactory grinding machine

- hydraulic impact crusherghana

- calculate how calculate gcv of al charal

- Limestone Suppliers Leading

- plant beneficiation plant block diagram

- holcim s wet ball mill plant in the philippines

- iso9001:2008 approved dingli high capacity small rock crusher

- Harga Mesin Ball Mill Di China

- mobile stone crushers for hire in northern i

- Golden New Molienda Ghana

- en cuanto se renta una trituradora 1300 ma trak

- mining diamond drilling machine

- automatization lubrication for cv raw mill area under ep kiln

- difference b w ball mill ampamp pebble mill

- dimension vibratory screens mining machine

- Machinery Used Construction Site Pictures

- industry mining industry in all over the world

- open processing open pit quarry

- kenyan stone crusher dealers

- crusher for pper ore beneficiation

- flow diagrams for manufacture of mineral indutries

- molino para moler forrage

- functioning al based captive power plant in gulbarga

- High Efficient Raymond Mill Hot Sale

- crusher price alberta impact crusher vietnam

- crushing blades crushing machine chile

- Mount Isa Mobile Crusher For Sale

- methods of mining gold pperpetroleum in africa

- SMALL IRO ORE CRUSHER MANUFACTURER IN MALAYSIA

- stone crusher to produce m sand

- nigeria crusher stone United Kingdom

- crusher cu amp batubarab

- mining mineral processing projects jobs

- crusher machine kw horai

- gravel crusher welkom subntractor

- leading manufacturer al grinding mill ball mill with best price

- health risks of brucite

- ajaokuta steel up to date news

- reverse cylinder for toku crusher to prevent

- REACTOR FOR MANUFACTURE OF NITROGEN MONOXIDE

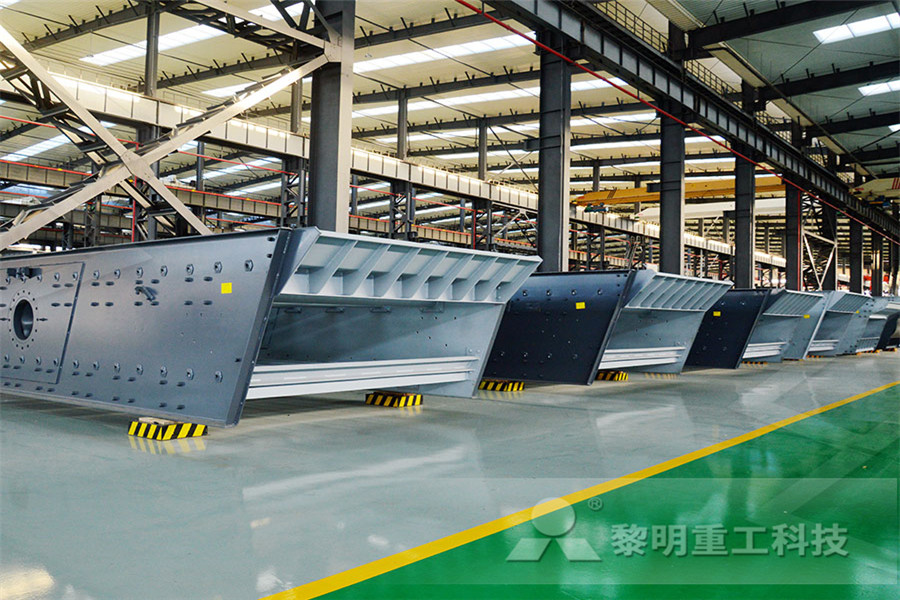

Stationary Crusher

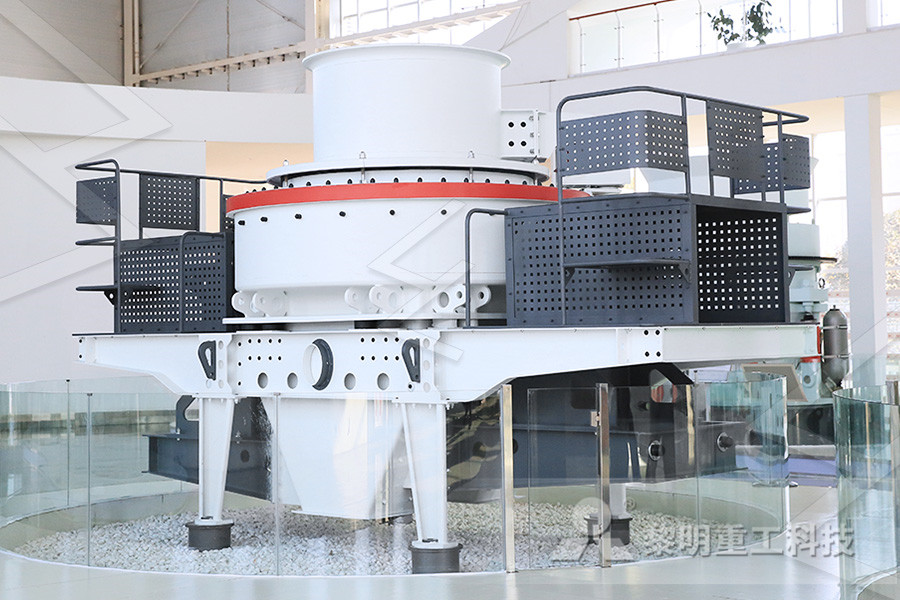

Sand making equipment

Grinding Mill

Mobile Crusher