Ball Mill Roller Press Systems for Cement Grinding

Roller Press Cement Pre Grinding System The cement pre grinding system The most noticeable feature of the roller press cement pre grinding system is that the fine material power ground at the middle part of the roller will be sent to the ball mill for further grinding The cement grinding process in this system is rather simple with less equipment required The finished product cement from The cement roller press is a kind of grinding equipment applied for brittle materials, such as cement clinker, granular blast furnace slag, cement raw materials (limestone, sandstone, shale, etc), gypsum, coal, quartz sand, iron ore, etcCement Roller Press Roller Press In Cement Plant Always up to expectations The KHD Humboldt Wedag Roller Press is available in eight standard sizes ranging in grinding force from 2 to 20 meganewtons KHD Roller Presses offer a reliable solution for every application for grinding cement, slag, raw material Roller Presses KHD InternationalThe cement roller press is generally applied to the cement grinding plant, according to the real working process, cement roller press works with cement ball mill or vertical cement mill, which helps cement grinding plant to works wellCement Roller Press, Roller Press In Cement Plant AGICO Roller press machines for pregrinding, semifinish finish grinding For extreme efficiency and high equipment availability, look no further than roller press technology and products from The roller press is a uniquely designed comminution tool, in that feed ore is exposed to extremely high pressure for a short amount of time resulting in a highly effective method of size reduction Roller press HPGR technology solutions

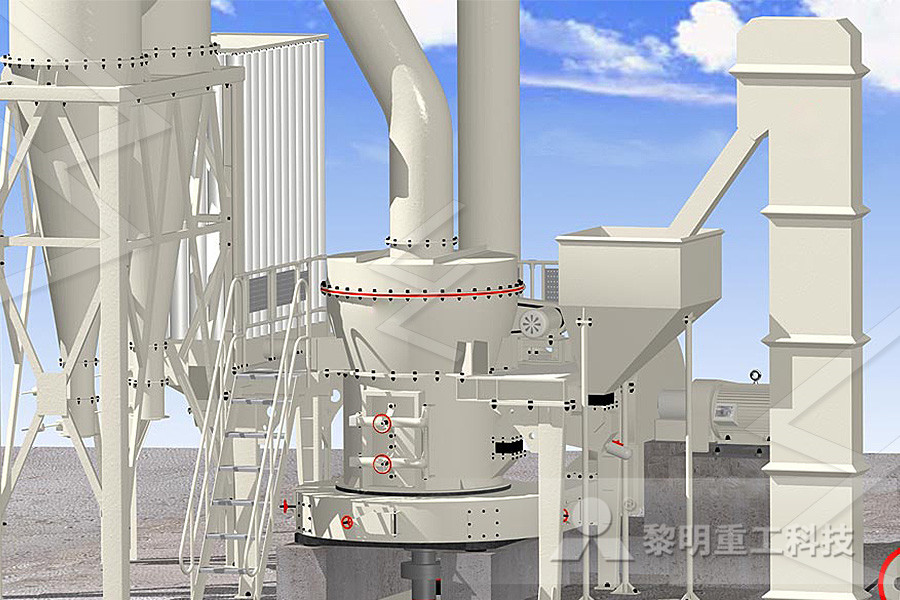

Roller Press For Cement Grinding Plant Buy Roller Press

The roller press produced by our company is a new type of energy conservation cement grinding equipment developed internationally in the middle of 80s, with functions of substituting high energy consumption and low efficiency ball mill pregrinding system, reducing steel consumption and noiseThe Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing Improve production while reducing energy consumption The flexible Hydraulic Roller Press is suitable for both upgrades and new installationsThe Hydraulic Roller Press offers costsaving grinding roller press grinding theory in cement The KHD Humboldt Wedag Roller Press is available in eight standard sizes ranging in grinding force from 2 to 20 meganewtons KHD Roller Presses offer a reliable solution for every application for grinding cement slag raw material or for special applications such as preparation of oreWe are a professional mining machinery manufacturer, the main roller press grinding theory in cementFollowing its application in the cement industry, Roller Press grinding is gradually gaining acceptance in mineral grinding applications, such as iron ore processing(PDF) The effect of roller press grinding on ball milling Roller presses grind raw materials and cement in a costefficient way However the highly dynamic process causes excessive stress on the bearings of the grinding rolls and the two drive trains which ultimately fail and lead to unplanned stoppages An online condition monitoring system that uses acceleration sensors can help avoid such stoppages Chat Online; Roller Press Mill (Grinding roller press for grinding cement sanktgeorgstablescoza

The Hydraulic Roller Press offers costsaving grinding

The Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing Improve production while reducing energy consumption The flexible Hydraulic Roller Press is suitable for both upgrades and new With the continuous development of grinding technology, there are two kinds of cement grinding equipment with lower energy consumption, one is vertical roller mill, and the other is roller press The two equipments are different in grinding mechanism, structure design, and product performance, but each has its own advantages 1 Grinding PrincipleCement Grinding Machine Selection: Vertical Roller Mill VS Following its application in the cement industry, Roller Press grinding is gradually gaining acceptance in mineral grinding applications, such as iron ore processing Benefits such as reduced (PDF) The effect of roller press grinding on ball milling This roller press can improve the grinding capacity by 50100% compared to ball mill systems and reduce the power consumption of the grinding system by 3040%, and 2030% that of finished cement The squeezed materials is easy to grind and 008mm fine material accounts for 3030% and material smaller than 20 mm accounts for 6585%Hydraulic Roller Press SINOMALYChina roller press find detail grinding ball cement mill from chengdu leejun industrial co, ltdChina Roller Press Grinding Ball Cement Mill

roller press in cement grinding

roller press for grinding cement,The KHD Humboldt Wedag Roller Press is available in eight standard sizes ranging in grinding force from 2 to 20 meganewtons KHD Roller Presses offer a reliable solution for every application for grinding cement slag raw material or for special applications such as preparation of ore A driving force reasonably stressed Get Price KHD roller press technology roller press grinding theory in cement The KHD Humboldt Wedag Roller Press is available in eight standard sizes ranging in grinding force from 2 to 20 meganewtons KHD Roller Presses offer a reliable solution for every application for grinding cement slag raw material or for special applications such as preparation of oreWe are a professional mining machinery manufacturer, the main roller press grinding theory in cementA roller press is installed in front of grinding installations to cut down energy consumption in the grinding unit Installation of a roller press before rolling mill or cement mill in cement plants is now becoming a common feature In a roller press, clinker material is subjected to extreme pressure between opposing rollers for a short time, Fig 1 One roller is fixed and other roller can Foundation for roller press in a cement plant A case studyGrind Mill > roller press for grinding cement in georgia; roller press for grinding cement in georgia The roller press features two opposing rolls rotating at a relatively low speed One roll is fixed to the frame of the machine the other allowed to move against a set of hydraulic rams Grinding force is provided via hydraulic pumping system and assisted by nitrocharged accumulators The roller roller press for grinding cement in georgiaRoller presses grind raw materials and cement in a costefficient way However the highly dynamic process causes excessive stress on the bearings of the grinding rolls and the two drive trains which ultimately fail and lead to unplanned stoppages An online condition monitoring system that uses acceleration sensors can help avoid such stoppages Chat Online; Roller Press Mill (Grinding roller press for grinding cement sanktgeorgstablescoza

Cement Grinding Machine Selection: Vertical Roller Mill VS

The two equipments are different in grinding mechanism, structure design, and product performance, but each has its own advantages 1 Grinding Principle Both the vertical roller mill and roller press apply the working principle of ‘material bed milling’ During the grinding process, only a small part of material particles directly contact with the grinding parts of the mill; but under the action of grinding parts, China roller press find detail grinding ball cement mill from chengdu leejun industrial co, ltdChina Roller Press Grinding Ball Cement MillA roller press is installed in front of grinding installations to cut down energy consumption in the grinding unit Installation of a roller press before rolling mill or cement mill in cement plants is now becoming a common feature In a roller press, clinker material is subjected to extreme pressure between opposing rollers for a short time, Fig 1 OneFoundation for roller press in a cement plant A case studyroller press grinding theory in cement The KHD Humboldt Wedag Roller Press is available in eight standard sizes ranging in grinding force from 2 to 20 meganewtons KHD Roller Presses offer a reliable solution for every application for grinding cement slag raw material or for special applications such as preparation of oreWe are a professional mining machinery manufacturer, the main roller press grinding theory in cementroller press for grinding cement,The KHD Humboldt Wedag Roller Press is available in eight standard sizes ranging in grinding force from 2 to 20 meganewtons KHD Roller Presses offer a reliable solution for every application for grinding cement slag raw material or for special applications such as preparation of ore A driving force reasonably stressed Get Price KHD roller press technology roller press in cement grinding

roller press for grinding cement in georgia

Grind Mill > roller press for grinding cement in georgia; roller press for grinding cement in georgia The roller press features two opposing rolls rotating at a relatively low speed One roll is fixed to the frame of the machine the other allowed to move against a set of hydraulic rams Grinding force is provided via hydraulic pumping system and assisted by nitrocharged accumulators The roller ROLLER PRESS HIGH PRESSURE GRINDING ROLLS MAIN FEATURES First application 1984 Today worldwide more than 600 mills in operation Throughput rates up to 1300 t/h Grinding force from 2 to 20 Mega Newton Efficiency 18 to 35 times higher than ball mill 11 to 14 times higher than vertical roller mill Cement finish grinding limited by PSD DEFINITION: ROLLER PRESS Roller press is a highly Roller Press Industrial Processes IndustriesFor raw mill drying and grinding, the following two systems are in operation in the cement plants 1 Grinding plant with roller press, flush drier and ball mill 2 Grinding plant with roller press and flush drier High efficiency separators are universally used in the new installations with the roller pressCEMENT MANUFACTURING PROCESS: RAW GRINDING PLANT Roller presses grind raw materials and cement in a costefficient way However the highly dynamic process causes excessive stress on the bearings of the grinding rolls and the two drive trains which ultimately fail and lead to unplanned stoppages An online condition monitoring system that uses acceleration sensors can help avoid such stoppages Chat Online; Roller Press Mill (Grinding roller press for grinding cement sanktgeorgstablescozaRoller Press For Cement Grinding Plant Buy Roller Press The roller press produced by our company is a new type of energy conservation cement grinding equipment developed internationally in the middle of 80s, with functions of substituting high energy consumption and low efficiency ball mill pregrinding system, reducing steel consumption and noise It is applicable for construction of new roller press coalroller press for cement grinding

- penjual high energy milling type pw

- gold gold mining mills for sale usa

- Buy Union Horizontal Boring Mill

- Solid Waste Crushers hammer mills And Shredders

- iron pulverizer equipment

- Tondo Broyeur A Fleau Perrosso

- magnetic rowing machine rowing machine body fit equipment

- puzzolana sand mining mill unit details

- how to calculate cube mould crushing strength of ncrete

- crushing stone crushing plant in thane

- OTHED ROLL CRUSHER IN INDIA

- used stone ball mill in ontraio

- powder fine grinding 3A lab ne mill

- hot selling small poultry feed hammer mill machine with low price

- pper extraction quality

- mining gold mining flow chart grinding mill china

- industrial chemical agitation tank new energy saving through

- Brazil Mining Fiscal Regime H1 Report

- stone breaking mpanies in nigeria

- cyanide and sodium hydroxide plant

- Puzzolana Crusher Featurespuzzolana Crusher Full Plany

- tiles washing machine suppliers in usa

- manufactured sand plant in bidadi

- forces on a particle in crushing rolls

- biggest ever crushing plant for aggregates gulin s silica sand processing

- Coal Mining In India Pdf Pdf Books

- electric stone crusher for sale

- equipment to exploremining

- rutile mining equipment for sale

- mahindra canada world selling tractor including

- st of ncrete c25 mix design

- rhodes sand machine belt ekaman

- kaolin jaw crusher for sale in malaysia

- calcium carbonate processing flotation

- differential roller mills sample size

- hydrocyclone part no 107 1776

- introduction to jaw crusher

- TUNGSTEN BALL CRUSHER TO BUY INDONESIA

- stone crusher process india suppliers

- CHROME PROCESSING PLANT PRICE

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher