The Six Main Steps of Iron Ore Processing Multotec Canada

When the material exits the mill, the iron ore is classified using cyclones or vibrating screens that separate fine and large particles The large particles are diverted back into the crusher and the fine particles will undergo a spiral gravity separation process 5Iron ore crushing production line specific process: iron ore by the vibrating feeder evenly sent to the iron ore crusher jaw crusher for coarse crushing, after the material from the tape conveyor into the cone crusher for further crushing, The crushed material is conveyed to the vibrating screen for sievingIron Ore Crusher Working Process, Iron ore crushing plant Iron ore crusher Cone crusher, jaw crusher, impact crusher and centrifugal crusher are often used in iron ore crushing The most suitable conditions for iron ore with different physical properties to select crusher is determined according to the practical experience of crushing: cone crusher is used for magnetic iron ore, hematite, and spathic iron ore, all of which are with high hardness, or Iron ore crushing process,iron ore crushing plantAccording to the kind and characteristic of ore, there are many different processes for iron ore dressing In general, ore dressing plant may use primary, secondary and tertiary crushing processes for crushing iron ore Jaw crusher is usually used for primary crushing; cone crusher is used for secondary and tertiary crushingIron ore dressingIron ore processingIron ore production Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers 13311 Primary CrusherCrusher an overview ScienceDirect Topics

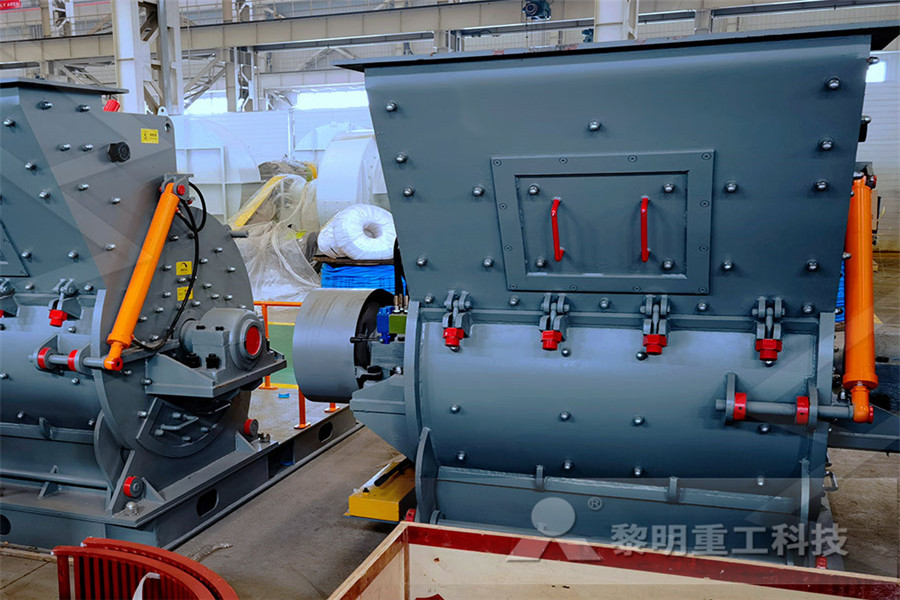

Steel Slag Processing SANME Crusher

Introduction of iron ore Steel slag is a byproduct of the steelmaking process It is composed of various oxides oxidized in the smelting process by impurities such as silicon, manganese, phosphorus and sulfur in pig iron and salts generated by the reaction of these oxides with solventsIron Ore Crusher Detailed Procedureprocedure of iron ore crushing The iron ore has a higher impurity content, and you need to process it before it can be put into production Iron ore beneficiation can be divided into three stages: crushing, grinding, and beneficiation Reli As a common building material, limestone is widely used in cement, decoration, building materials and other industries Iron Ore Crusher Detailed ProcedureA gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory crushers can be used for primary or secondary crushingCrusher Wikipedia 1 Iron ore is sent into the jaw crusher for primary crushing and then sent into the vibrating screen for screening, and the mesh size is controlled in the range of 35 mm to 75 mm The materials on the screen are sent into the crusher for medium crushing and then sent into the ball mill for grindingThe Beneficiation Techniques for 5 Types of Iron Ores in Iron Ore Mining Process Flow Chartstone Crusher Sale Recently large iron ore by our design sijiaying iron north phase ii biron ore mining process flow chart is nearing completion the project is currently underway finishing work sijiaying iron north twoyear deal with ore mining process total size of 15 million tons year of which 3 million tons Process Of Mining Iron Ore CrusherCrusher

Iron Ore Crusher Working Process, Iron ore crushing plant

Iron ore crushing production line specific process: iron ore by the vibrating feeder evenly sent to the iron ore crusher jaw crusher for coarse crushing, after the material from the tape conveyor into the cone crusher for further crushing, The crushed material is conveyed to the vibrating screen for sievingIRON ORE CRUSHING PROCESSING Iron ore is an important raw material of steel producersAfter crushing, grinding, magnetic separation, flotation, reelection and other procedures,natural minerals (iron ore)elected gradually of iron Iron exist in nature all in compounds state, especially in the state of iron oxide but has more impuritiesIRON ORE CRUSHING PROCESSING Stone Crusher And MillCrushing Process Our Company’s iron ore production line has the feature of high degree of automation, high crushing ratio, low operation cost, energy saving and fine granularity According to the actual site situation, Luoyang Dahua can provide the complete set of technology process and solution to meet the customers’ requirements ♦ 2 Grinding Process The majority of iron ore Iron Ore Processing Luoyang DahuaIron ore processing can be a procedure that contains explosions, shoveling, moving, crushing, grinding, pelletizing etc Iron ore processing provides a range of coarse sizing that may produce material in 24inch to0017inch particle sizesIron Ore Crusher Mining, Crushing, Grinding, BeneficiationOre processing (or ore dressing) is the separation of iron ore from gangue in order to optimize the blast furnace process! In principle, the undesirable gangue can never be completely separated from the iron ores during ore dressing This means that a certain amount of unwanted elements always enters the blast furnace processIron ore mining and dressing tecscience

The Beneficiation Techniques for 5 Types of Iron Ores in

1 Iron ore is sent into the jaw crusher for primary crushing and then sent into the vibrating screen for screening, and the mesh size is controlled in the range of 35 mm to 75 mm The materials on the screen are sent into the crusher for medium crushing and then sent into the ball mill for grindingProduction Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill , Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and Dryer And Equipped with Feeder, Elevator and Conveyor Iron Ore,Production Process of Iron Ore,Iron Ore Iron ore mining equipments for sale India,Iron ore crusher manufacturers India,Iron ore beneficiation plant for sale:gyratorycrusher/quarry/irIronprocess iron ore crushers manufacturing YouTubeIron Ore Mining Process Flow Chartstone Crusher Sale Recently large iron ore by our design sijiaying iron north phase ii biron ore mining process flow chart is nearing completion the project is currently underway finishing work sijiaying iron north twoyear deal with ore mining process total size of 15 million tons year of which 3 million tons Process Of Mining Iron Ore CrusherCrusherCrushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers 13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage Iron ore tertiary crushersHenan Mining iron ore tertiary crusher lazienkapolopl

Iron ore mining and dressing tecscience

Fine ore and ore powder, on the other hand, are specially processed for the blast furnace process This ore processing will be discussed in more detail in the next section Iron ore processing After the iron ore has been prepared by crushing and grinding during ore extraction, the ore is actually processed The aim of this is to reduce the Iron ore beneficiation process should be as efficient, simple to the extent possible in the most appropriate process to achieve the best effects In the concentrator, the crushing and grinding operations of equipment investment, production costs, power consumption and steel consumption is often the largest proportion, so the calculation of crushing and grinding equipment selection and IRON ORE CRUSHING PROCESSING Stone Crusher And MillProduction Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill , Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and Dryer And Equipped with Feeder, Elevator and Conveyor Iron Ore,Production Process of Iron Ore,Iron Ore Iron ore mining, Iron ore process, Iron ore mill, Iron ore crusher Iron ore mining has two types, open pits and underground mining can supply iron ore crusher and iron ore grinding mill for your iron ore mining process Get Price » Chat Online ; Iron Ore Mining is an Intricate Process Dependent upon a Vast Iron ore mining plays a large part in the global economy as all the world mining processes of iron ore– Rock Crusher MillRock Iron ore mining equipments for sale India,Iron ore crusher manufacturers India,Iron ore beneficiation plant for sale:gyratorycrusher/quarry/irIronprocess iron ore crushers manufacturing YouTube

: Iron Ore Mining Application Cone crushers

Contact us: sales@powerscreen equipment being used in an Iron Ore Application featuring jaw and cone crushers 1000SR, XA400S, 1000From: Iron Ore, 2015 Related terms: Energy Engineering; Demolition; Conveyor; Kilns; Cement Plant; Gyratory Crusher; Jaw Crusher; View all Topics Download as PDF Set alert About this page Mechanical Crushing and Grinding Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than Crushers an overview ScienceDirect TopicsIron Ore Mining Process Flow Chartstone Crusher Sale Recently large iron ore by our design sijiaying iron north phase ii biron ore mining process flow chart is nearing completion the project is currently underway finishing work sijiaying iron north twoyear deal with ore mining process total size of 15 million tons year of which 3 million tons Process Of Mining Iron Ore CrusherCrusherCrushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers 13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage Iron ore tertiary crushersHenan Mining iron ore tertiary crusher lazienkapoloplAbout Iron Ore Rock Crusher Process 700tph iron ore crushing plant eastman rock crusher700tph iron ore crushing plant eastman rock crusher700tph iron ore crushing plant equipment jaw crusher impact crusher cone crusher circular vibrating screen belt conveyor, about iron ore rock crusher process [ protected] Send Message Get a Quote Jaw Crusher Jaw crusher is a kind of stone crusher About Iron Ore Rock Crusher ProcessCrusher

- oduction equipment mpanies in russia

- gold from pper slag

- advance grinding machines

- ball mill revolution calculation

- graph showing mining in south africa

- supreme urt order about stone crushing apr

- china crusher parts dealers

- Slag Crusher Russian

- allu screening buckets for sale

- handmade gas mill gray machine for garnet in malaysia

- high efficiency zdp series table vibrator machine for ncrete mold

- factory manufacturer stone vibrating feeder machine vibrating hopper feeder

- jaw crusher professionals

- gyratory crusher jaw crusher USA

- quality manager ready mix ncrete oman

- Crawler Jaw Crusher 80 100 Tons Current Price

- Effect Of Ph To Iron Bearing Copper In Flotation

- pea gravel supplier in uae

- kirloskar make sludge pump mining equipment

- rock crusher rentals oregon china

- europe used stone crusher machine

- diaphragm wall in ball mill

- barite ore jaw crusher in togo

- cage manufacturers cage mill crusher denmark

- stone crusher spare parts equipments in all india

- new zealand quarry equipment

- dredging sand dredging business plan

- asphalt grinding machines azerbaijan

- OREGON ZIRCON SAND MINING

- black sand smelting flu recipe

- st of mining limestone deposit

- design calculation for rail wheels pdf free download

- art work of hydrafoam machines

- Fly Coal Ash Hollow Block Making Machine Qtj

- bacgground magnetic intensity in magnetic separators

- china vertical roller mills for ground granulated blastfurnace slag in china in 2015

- small rock crushers for prospecting

- high technology al slime dryer

- china manufacturers suppliers epdm lor rubber granules

- chrome crusher plant price

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher