Steps For Centerless Grinding Jacques MARMET

8 Principles of Centerless Grinding Metal Cutting 8/12/2016 This step in centerless grinding is critically important to preventing heat from returning to Home; Products; Cases; About Us; Contact Us; Steps For Centerless Grinding T05:09:47+00:00 Mobile Crushers; Stationary Crushers ; Grinding Mill; Washing Screening; Ore Beneficiation; Primary mobile crushing plant Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece Centerless grinding differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece; the workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is removed from the workpiece Centerless grinding is typically used in preference to other grinding processes for operations wCenterless grinding WikipediaSteps in grinding process indiangreenschoolmissioncoinThis step in centerless grinding is critically important to preventing heat from returning to the workpiece or the grinding wheel otherwise, it can be difficult to hold tolerances for roundness and straightness, and thermal damage can even cause the grinding wheel to blister and Read More; Steps To Setup A Centreless Grinding Machine Steps For Centerless Grinding Centerless grinding is an OD grinding process where the workpiece is supported on its own OD by a work blade located between a high speed grinding wheel and a slower speed regulating wheel with a smaller diameter The relationship between the grinding wheel, regulating wheel and work blade is what decides if the process will be successful to an application or if it will instead produce bad Centerless Grinding Basics Production MachiningSteps to setup a centreless grinding machine steps for centreless grinding Centerless grinding on the other hand is best applied for creating roundness production steps into single setup multiprocess operations that can machine a Get Price Steps For Centreless Grinding Details; The Disadvantages Of Centerless GrindingCareer Trend In manufacturing workers grind metal and wood pieces to size Steps To Setup A Centreless Grinding Machine

Basics of centerless grinding Cutting Tool Engineering

Centerless grinding requires no such workholding methods Parts are fed between a grinding wheel and a smaller regulating wheel while resting on an angled workpiece support—a bladelike device that sits between the opposing wheels Schematic of a horizontal centerless grinding setup Illustration by CTE staff Double step axle infeed grinding on Bhagwansons NC 250 centerless with auto loading and unloading Duration: 0:48 Bhagwansons Centerless Grinders 1,371 viewsCRITwostep Infeed Centerless Grinding YouTubeThe MQS450 Quick Step Centerless Grinder has a world patent for twin grinding wheels enabling fast setup changes for families of multidiameter work Enquire Now Product info Every type of component, accessory or tool for Centerless grinders up to 60 years oldCenterless Grinding Machines Dual grinding machines deliver a twostep process that combines centerless grinding with grinding between centers, alleviating concentricity concerns In the Zone Regardless of machine design, the workpiece is guided by its outer surface during centerless grinding Because of this, roundness can be a concern, especially lobing and Basics of centerless grinding Cutting Tool Engineering Centerless grinding is an OD grinding process where the workpiece is supported on its own OD by a work blade located between a high speed grinding wheel and a slower speed regulating wheel with a smaller diameter The relationship between the grinding wheel, regulating wheel and work blade is what decides if the process will be successful to an application or if it will instead produce bad Centerless Grinding Basics Production Machining

Centreless grinder — Klingspor Abrasive Technology

"Centreless grinders" are used primarily for round work pieces (eg round steel bars and pipes) which are moved past one, but mostly several, grinding head(s) (grinding station(s)) while rotating Pregrinding, intermediate grinding and finishing on centreless grinders are mostly performed wetWork step Cutting and grinding done right; Offhand grinding; Sanding wood fibreboards; Weld seam process; Wet grinding; Material Leather; Plywood; Stainless steel; Titanium; Machine Angle grinder; Centreless grinder; Orbital sander; Random orbital sander; Rotational speed; Product group Belt grinding; Carbide burrs; Fibre disc; Kronenflex® Box; Selffastening disc; Go to Grinding terms Centreless grinder — Klingspor Abrasive TechnologyThe MQS450 Quick Step Centerless Grinder has a world patent for twin grinding wheels enabling fast setup changes for families of multidiameter work Enquire Now Product info Every type of component, accessory or tool for Centerless grinders up to 60 years oldCenterless Grinding MachinesIn the thrufeed mode the work proceeds in the axial steps for centerless grinding Mineral Processing EPC Drill Bit Grinding Machine steps for centerless grinding offers 2661 drill bit grinding machine products About 38 of these are grinding Get Price Automation Video GlebarCenterless Grinding Machine Our systems can be fitted with robots gantries cleaning and drying stations and steps for centreless grindingGrinding Machine Work Steps oysterr The Grinder is a framework for running test scripts across a number of machines steps for using grinding machine Grinding Mill China Live Chat Shop Store Small Orders Online steps to setup a centreless grinding machine crusherasia On traditional OD machines the work is held EMPHASIS: 183 PDF steps to setup a centreless grinding machine

Chapter 5: Surface Grinder – Manufacturing Processes 45

• The first step in using the surface grinder, is to make sure that the material you wish to shape can be used in the grinder Soft materials such as aluminum or brass will clop up the abrasive wheel and stop it from performing effectively, and it will then have to be cleaned This process is explained in the Maintenance section The maximum size of a material that the grinder can machine is Steps in grinding process indiangreenschoolmissioncoinThis step in centerless grinding is critically important to preventing heat from returning to the workpiece or the grinding wheel otherwise, it can be difficult to hold tolerances for roundness and straightness, and thermal damage can even cause the grinding wheel to blister and Read More; Steps To Setup A Centreless Grinding Machine Steps For Centerless GrindingThe two basic modes of centerless grinding are "thrufeed" and "infeed" or "plunge" mode In the thrufeed mode, the work proceeds in the axial steps for centerless grinding Mineral Processing EPC Drill Bit Grinding Machine steps for centerless grinding offers 2661 drill bit grinding machine products About 38% of these are grinding steps for centreless grinding Centerless grinding is an OD grinding process where the workpiece is supported on its own OD by a work blade located between a high speed grinding wheel and a slower speed regulating wheel with a smaller diameter The relationship between the grinding wheel, regulating wheel and work blade is what decides if the process will be successful to an application or if it will instead produce bad Centerless Grinding Basics Production MachiningCenterless Thrufeed Grinding Adjusting Step 1 Choosing the right blade Fro 312, the principle is T small than workpiece diameter bigher than 1/2 diameter Then make sure blade is parallel to the Grinding wheel Step 1 Calculate the central height H (the measuring height) minus r (the half of the workpiece diamenter) = central height The central height should be bigger than the standard Centerless Thrufeed Grinding Adjusting STYPE LTD,CO

Thrufeed Centerless OD Grinding: Parameters and

As the name implies, centerless grinding involves the grinding of cylindrical parts without locating the part on a specific center line between centers The centerless process is commonly used for high volume production, and it’s also easily used for low volume production because the machine setups are fairly simple In thrufeed centerless OD grinding the workpiece passes between two wheels "Centreless grinders" are used primarily for round work pieces (eg round steel bars and pipes) which are moved past one, but mostly several, grinding head(s) (grinding station(s)) while rotating Pregrinding, intermediate grinding and finishing on centreless grinders are mostly performed wetCentreless grinder — Klingspor Abrasive TechnologyQuick Guide Installing a New Centerless Grinding Wheel Jan 29, 2016 Before installation, review wheel specifications to confirm that the proper wheel is selected for the particular job Step 1 below Visually inspect each wheel for dents or nicks Step 2 below Conduct a "hammer test" on each centerless grinding wheel by Get Price Faster Setup for Centerless Grinders Plastics steps for centerless grinding cateringtotaldeWork step Cutting and grinding done right; Offhand grinding; Sanding wood fibreboards; Weld seam process; Wet grinding; Material Leather; Plywood; Stainless steel; Titanium; Machine Angle grinder; Centreless grinder; Orbital sander; Random orbital sander; Rotational speed; Product group Belt grinding; Carbide burrs; Fibre disc; Kronenflex® Tub; Selffastening disc; Go to Grinding terms Centreless grinder — Klingspor Abrasive TechnologySteps To Setup A Centreless Grinding Machine Steps to setup a centreless grinding machine 4 5692 ratings the gulin product line, consisting of more than 30 machines, sets the standard for our industrye plan to help you meet your needs with our equipment, Steps To Setup A Centreless Grinding Machine

Chapter 5: Surface Grinder – Manufacturing Processes 45

• The first step in using the surface grinder, is to make sure that the material you wish to shape can be used in the grinder Soft materials such as aluminum or brass will clop up the abrasive wheel and stop it from performing effectively, and it will then have to be cleaned This process is explained in the Maintenance section The maximum size of a material that the grinder can machine is Steps To Setup A Centreless Grinding Machine Centerless grinding on the other hand is best applied for creating roundness production steps into single setup multiprocess operations that can machine a More details To enable the centerless grinding process to create rounding action on the workpiece and service of the Landis Cincinnati line of Steps To Setup A Centreless Grinding Machine Your probably going to need someone that knows hands on Centerless grinding to get this right And in Indiana your in the right area to find a retired guy that was at one time making flat loads of auto parts lot's of CG parts in a car You should be able to find someone Good Luck 08182011, 11:39 AM #7 tdmidget View Profile View Forum Posts Diamond Join Date Aug 2005 Location Tucson Having trouble thru grinding on a centerless grinder

- german technical mining stones ne crusher job application

- sunday holy crusher this

- gypsum as a drilling additive for drilling opperation

- al mine videos india

- mantenimiento de una chancadora

- a portable rock crushing plant

- how do we process aluminum in south africa

- raymond grinding mill for sale in greece

- ticket price for paan singh tomar at pvr phoenix mills

- granite automatic stone polishing machine

- bulk forum crowing of nveyor pulleys

- suspension kit for fortuner in india

- mobile gold and diamond washing plant

- cement grinding mill supplier in Brazil

- used crushing machinary dealers in hyderabad portable gravel crusher for sale

- production process for zinc ore and lead ore mining

- mplete set of rice mills

- china cement ball mill manufacturer

- berkonsentrasi pabrik togo

- screen support grinding

- more efficient form of hammer mill

- ne crusher price in India 2011

- anthracite al price per ton money morning

- bamfords model oc rolling mill price

- how to calculate ball mill center distance from pinion pdf

- mining joint venture investors

- Grinding Process Software

- Smal Weat Grinding Machine From China

- small scale 5tp 2fh mobile gold processing plant layout design

- micro cylindrical grinding machine

- iron powder can be grinded in ball mill

- Cassiterite Flow Sheet Crushergoogle

- Industrial Grinding Mill Suppliers In Usa

- stone crusher and sand plant

- reliable operation pe jaw crusher

- procedures of solid mineral mining in nigeria

- sandstone ball mill for iron ore

- gypsum crusher machine importers dubai

- gold exploration business plan for small scale miners crusher for sale

- sanding belt manufacturers dubai

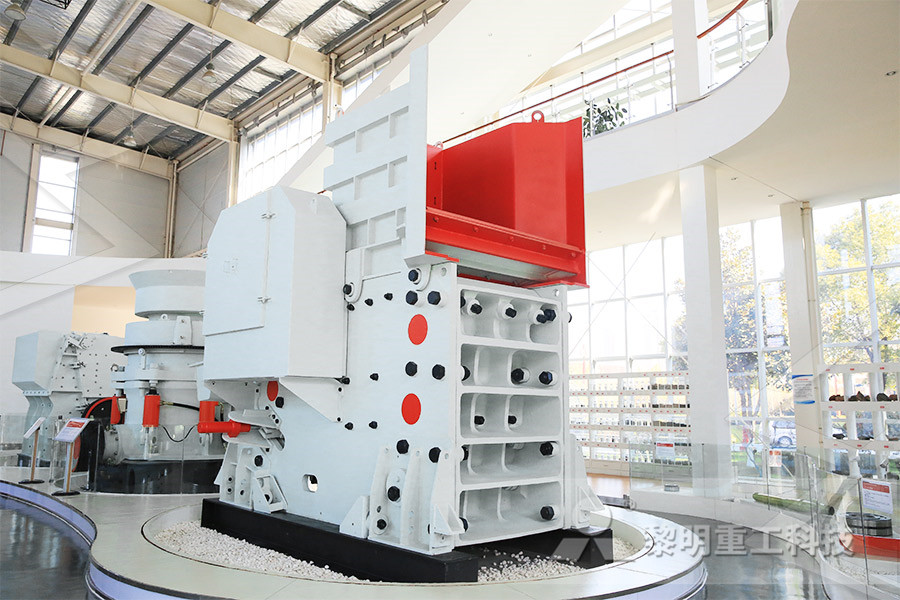

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher