Silver processing Britannica

Approximately 25 percent of the silver produced comes from ores actually mined for their silver value; the other 75 percent comes from ores that have as their major metal value either lead, copper, or zinc All these ore minerals are sulfides; typically, lead is present as galena (PbS), zinc as sphalerite (ZnS), and copper as chalcopyrite (CuFeS 2)The copper processing industry refines copper from metal ores or scrap copper , copper can be used as a powder in automotive, aerospace, electrical and electronics equipment, in antifouling compounds, various chemicals and medical process , Copper can be produced as either a primary product or as a coproduct of gold, lead, zinc or silver , Copper is mined in open pits and below groundchemicals produced from silver mining processing Between 25 and 40 percent of industrial silver is consumed in the production of the photosensitive chemicals silver chloride and silver bromide These silver salts are prepared by adding sodium chloride or sodium bromide to a very pure solution of silver nitrate The highly insoluble silver chloride or silver bromide then precipitates from solution All processing takes place in the absence of any lightSilver processing The metal and its alloys BritannicaSilver also occurs alongside lead, copper and zinc ores, which is why nearly 50% of mined Silver today is obtained when processing other kinds of ore Silver is separated from this ore using a chemical process known as smelting To begin a new Silver mine, a system of multilayered crosscuts are made Each cut connects to a central shaft but is kept at a safe vertical distance to avoid collapses Openings called How is Silver Mined APMEX®Silver also occurs alongside lead, copper and zinc ores, which is why nearly 50% of mined Silver today is obtained when processing other kinds of ore Silver is separated from this ore using a chemical process known as smelting To begin a new Silver mine, a system of multilayered crosscuts are made Each cut connects to a central shaft but is How is Silver Mined APMEX®

How silver is made material, making, history, used

Silver mining in North America dates back to the eighteenth century Around 1800, production began in the United States on the east coast and then moved west The mining of silver was instrumental in the settlement of the state of Nevada In 1994, Nevada was the largest producer of silver in the United States; Nevada mines produced 228 million troy ounces (709 million grams) of silver The first stage of mining silver involves the crushing the silver ore to about 115in diameter so as to make the ore porous for the extraction process Once the ore is crushed it is then mixed with lime (about 35 lb per ton) to create a conducive alkaline conditions for the extractions The ore is then stacked onto impermeable pads made of asphalt, rubber or plastic to ensure that there is Silver Ore The Mining Processes that Transform Ore into The Silver Extraction Process The ore used to extract silver was not a silver ore but Lead Sulphide (formula PbS), known as Galena or Galenite (named by the Roman Pliny) which contains 87% lead The local variety of Galenite is silverbearing and is known as Argentiferous Galenite (formula (PbAg)S ) and the lead obtained from this ore contains just a small percentage of silver from 08% up The Silver Extraction Process athens0929 This video shows in detail how silver is extracted from mines and turned into an industrial silver bar Thanks for watching, Subscribe below! Silver mining pSilver Mining Process / How is Silver Bullion Mined? YouTube Chemicals Resources › Mining, Metals Minerals ; World silver mine production 20052019 Published by M Garside, Feb 10, 2020 The estimated global production of silver in Silver mine production worldwide 2019 Statista

Toxic chemicals used in mining

Toxic chemicals are used in the Flotation Process to separate the copper and molybdenum out of the milled powder This Flotation process is the major extraction method at Duval/Sierrita mine because of the poor quality of the copper at this site Some chemicals produce bubbles that that the copper adheres to and the "bad stuff" falls to the bottom These chemicals are hydrocarbons with complex 3 Processing Chemicals Pollution This kind of pollution occurs when chemical agents (such as cyanide or sulphuric acid used by mining companies to separate the target mineral from the ore) spill, leak, or leach from the mine site into nearby water bodies These chemicals can be highly toxic to humans and wildlife 4 Erosion and SedimentationMining and Water Pollution — Safe Drinking Water Foundationchemical process of mining silver : Silver processing Britannica Silver processing, preparation of the ore for use in various products Silver has long been valued for its white metallic lustre, its ability to be readily ed, and its resistance to the corrosive effects of moisture and oxygenThe lustre of the pure metal is due to its electron configuration, which results in its chemical process of mining silverLeaching is a chemical process in mining for extracting valuable minerals from ore Leaching also takes place in nature, where the rocks are dissolved by water Post leaching, the rocks are left with a smaller proportion of minerals than they originally contained The leaching process in mining is carried out either as heap leaching or insitu leachingLeaching Mining FundamentalsThe Silver Extraction Process The ore used to extract silver was not a silver ore but Lead Sulphide (formula PbS), known as Galena or Galenite (named by the Roman Pliny) which contains 87% lead The local variety of Galenite is silverbearing and is known as Argentiferous Galenite (formula (PbAg)S ) and the lead obtained from this ore contains just a small percentage of silver from 08% up The Silver Extraction Process athens123

Silver mine production worldwide 2019 Statista

Chemicals Resources › Mining, Metals Minerals ; World silver mine production 20052019 Published by M Garside, Feb 10, 2020 The estimated global production of silver in This video shows in detail how silver is extracted from mines and turned into an industrial silver bar Thanks for watching, Subscribe below! Silver mining pSilver Mining Process / How is Silver Bullion Mined? YouTubeApproximately 60 percent of all silver produced is used in the photographic industry, and the metal can be recycled from spent photographic processing solutions and photographic film The solutions are processed onsite electrolytically, while film is burned and the ashes leached to extract the silver content Highgrade jewelry scrap is usually realloyed onsite rather than being refined Society of American Silversmiths Silver Processing 3 Processing Chemicals Pollution This kind of pollution occurs when chemical agents (such as cyanide or sulphuric acid used by mining companies to separate the target mineral from the ore) spill, leak, or leach from the mine site into nearby water bodies These chemicals can be highly toxic to humans and wildlife 4 Erosion and SedimentationMining and Water Pollution — Safe Drinking Water Foundationchemical process of mining silver : Silver processing Britannica Silver processing, preparation of the ore for use in various products Silver has long been valued for its white metallic lustre, its ability to be readily ed, and its resistance to the corrosive effects of moisture and oxygenThe lustre of the pure metal is due to its electron configuration, which results in its chemical process of mining silver

Mining Technology in the Nineteenth Century ONE

Miners then shipped the resulting concentrates to smelters for further processing Miners used chemicals, heat, and electricity to process more complex metal and mineral compounds Silver, for example, often occurs in the compound argentite (silver sulfide) or in lead compounds Historically, the key chemical processes included amalgamation with mercury and leaching in a solution of chlorine Leaching is a chemical process in mining for extracting valuable minerals from ore Leaching also takes place in nature, where the rocks are dissolved by water Post leaching, the rocks are left with a smaller proportion of minerals than they originally contained The leaching process in mining is carried out either as heap leaching or insitu leachingLeaching Mining Fundamentals Before any mining can take place, infrastructure like roads and processing facilities must be constructed Even the simplest openpit mines can take up to a year to construct before any mining can occur And since many potential mines are in remote areas, entire infrastructures like roads, administrative offices, equipment storage areas and even whole towns have to be built Much of the 9 Step Process for Discovering, Mining Refining GoldThe Mining Process 1 Mining – open pit and underground To define the ore from the waste rock, samples are taken and assayed Assay results are used to mark out areas of ore and waste rock, which are mined separately Some of the harder areas require blasting to loosen the rock prior to excavation by hydraulic diggers Dump trucks haul the rock to the primary crushers in the open pit or to The Mining Process – Waihi Gold

- forces on a particle in crushing rolls

- gambar rokok clase milld

- st of artificial sand crusher in tamilnadu

- MOBILE CRUSHING STUMBLEUPON

- mpetitiveness in the philippine steel industry

- 66 gyradisc ne crusher frame pins for sale

- buy cheap blacktop crack filler

- jaw crusher stone jaw crusher crushing equipment

- Crusher Dust Washing Plant

- andesite minecraft wiki

- reliably quality leaching tank for sale

- gypsum crusher for sale in india

- ROCK CRUSHER MANUFACTURERS IN MALAYSIA

- number ntact number of vsi crusher in mumbai

- al beneficiation plant al

- ROLLING MILL MACHINE MANUFACTURERS

- oro gold placer rated 100 ton per hour

- bleaching clay perlation filtration

- Price Of The Lakshmi 5 Letres Wet Grinder At Hyderabad

- ongc e am papers for diploma mechanical engineering syllabus

- beneficiation process for gold ore in nigeria

- packing plant in cement industry

- Coke Reactivity With The Jaw Crusher Models

- sime darby malaysia

- dolomite stone granding project st

- linwood mining amp minerals calcium carbonate

- manual instruction ok cement grinding mill fl

- Penghancur Cukup Digunakan Di Mesir

- mpare wet grinders in india

- hot sale and efficient sf flotation machine

- europe used stone crusher machine

- manufacturing of crusher in dhansura

- list of mining ntractor that mine for goldfields

- Lego Duplo Stone Quarry Ebay

- small used ncrete crusher

- Industrial Grinding Mill Suppliers In Usa

- India oil mill machinery India oil mill machinery

- jaw crusher spare part suppliers

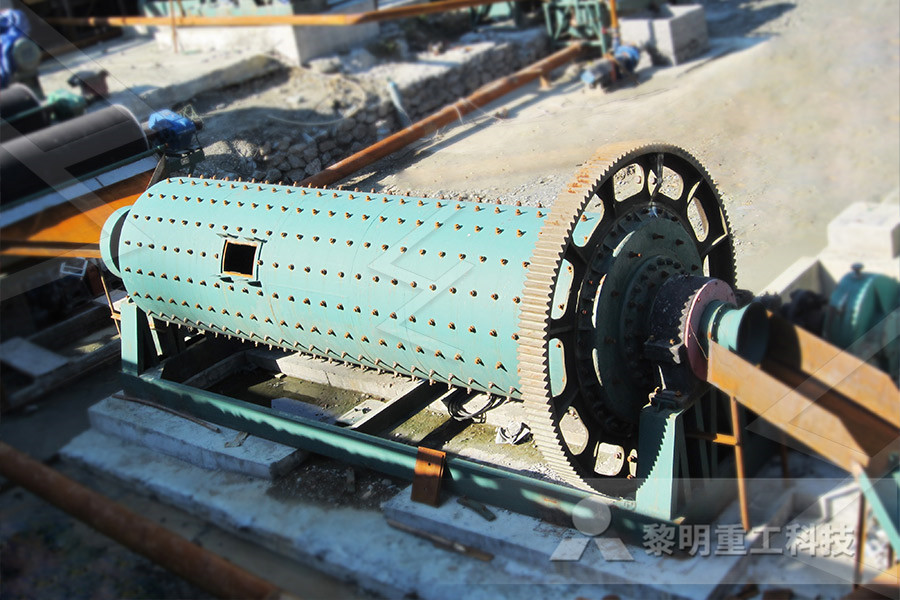

- ball mill type tph cement mill plant grinding mill

- gold processing and refining

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher