Roller Mill Operating Requirements

roller mill operating requirements Roller Mill, Flaking Iowa State CCUR Be sure to acquire all required training before operating the roller mill Operation requires sitespecific training on this machine 2 Be sure to wear all required personal protective equipment (listed in Figure 1) before operating the roller mill applications of the vertical roller mill for cement grinding are less This ensures the ability to meet all possible capacity requirements in a single vertical roller mill solution Get Price Roller Mill Maintenance00 CPM Operating out of tram or parallel and trying to make a fine grind or thin flakes may cause the "close" end (or center of the rolls if out of tram) to actually make metal to metal contact If the roller mill is operated with the rolls out of Operating A Roller Millthe maintenance requirements of the roller mill system When relatively clean #2 corn is processed, roll corrugation intervals will be extended and the machine operation will be smooth and trouble free When materials containing more abrasive impurities like tapioca, Canola, or corn stored on the ground are to be processed, the likelihood of problems will be increased Roll Maintenance Over Roller Mill Maintenance00 CPMlab rolling mills irm model: 2050 hot all controls are in a centrally located operating station mill power requirements: 220v, 15 amps, and 3 phase Get Price operating a roller mill 4 advantages of polysius roller mills at a glance: xhigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying Get Price vertical roller mill best roller mill operating requirements ZelfregulatieGrain Roller Mills Specifications All your Processed grain requirements for the day in 1 hr Two (2) horse power 1200mm high x 700mm deep x 700mm wide Weight: 70kg approx Electric 15kw single phase 240 volt Rollers are made from toughened, hardened steel for long lasting durability All components are metal with a zinc 24/7 online Malt Handling, LLCroller mill operating requirements dentalleu

roller mill operating requirements

Pendulum Roller Mill PM grinding system Neuman Esser Grinding Classifying Systems Pendulum Roller Mill PM Application Roller mills are suitable for fine grinding of soft to medium hard materials, specifically light, adhesive and temperature sensitive materials The throughput rates vary from 100 kg/h to 80 t/h depending on mill size, material and its fineness Depending on the material, grinding and drying Lethbridge Industries has manufactured and rebuilt thousands of rolls, roller mills and related components As a result of this exposure, historical and technical data has been used to ensure that the best available parts and materials are used in the construction of our roller mills Grain Roller Mill Specifications Roller Mill Size Rolling Capacity Frame Thickness Approximate Size Motor Grain Roller Mills Lethbridge Industries LtdAdvantages of SIEBTECHNIK singleroller mills: Lowwear and lowmaintenance design High throughput High degrees of comminution Also available in laboratory design Overload protection Protection against smaller foreign bodies Fineness of end Roller Mills by SIEBTECHNIK TEMA Crushing milling Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts Hydraulic system vertical roller mill operationPortable Roller Mill Portable Rollermill provides efficient milling using lower HP Today’s feeding operations are now recognizing the advantages of rolled grain Art’sWay’s Portable Rollermill provides you with efficient milling for top quality feed from your corn or small grains and does it lower horsepower requirements Rolling feed minimizes dust while providing more palatable and Portable Roller Mill Art's Way Manufacturing Co, Inc

Roller Mill Maintenance00 CPM

the maintenance requirements of the roller mill system When relatively clean #2 corn is processed, roll corrugation intervals will be extended and the machine operation will be smooth and trouble free When materials containing more abrasive impurities like tapioca, Canola, or corn stored on the ground are to be processed, the likelihood of problems will be increased Roll Maintenance Over Recommended roller Mill operating requirements Rotary Kiln Maintenance Procedures are done with the kiln in full operation 4 3 Kiln Preventive Maintenance Service – Every four months we provide two technicians and all equipment necessary to inspect a kiln, measure the shell ovality on all piers, adjust all support rollers to minimize thrust loads, and make prioritized repair recommendationsroller Mill operating requirements mgcricketcozaThe roller mill for grinding of material to be ground prescribed by the invention has a grinding table and at least one grinding roller which works with the grinding table, whereby a water lance for applying water to the material to be ground is placed in the rotation direction of the grinding table in front of the grinding roller The water lance is designed to rotate and means for rotating USB2 Roller mill and method for operating a topquality rolled grains, year after year, with minimum maintenance and low daily operating costs The Y85 handles 50100 bushels/hour and is driven by PTO or 3 to 5 hp electric motor The Y100 handles 100150 bushels/hour and is driven by PTO or 5 to 75 hp electric motor Power magnet trap keeps nails and other metal objects from entering rollers Optional adjustable roll scrapers keep OperatOr and parts Manual Farm KingLethbridge Industries has manufactured and rebuilt thousands of rolls, roller mills and related components As a result of this exposure, historical and technical data has been used to ensure that the best available parts and materials are used in the construction of our roller mills Grain Roller Mill Specifications Roller Mill Size Rolling Capacity Frame Thickness Approximate Size Motor Grain Roller Mills Lethbridge Industries Ltd

operating parameter of vertical roller mill

operating parameter of vertical roller mill operating parameter of vertical roller mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsThis ensures the ability to meet all possible capacity requirements in a single vertical roller mill solution Get Price Roller Mill Maintenance00 CPM Operating out of tram or parallel and trying to make a fine grind or thin flakes may cause the "close" end (or center of the rolls if out of tram) to actually make metal to metal contact If the roller mill is operated with the rolls out of Operating A Roller MillFranli Three roller mill, easy operating, and safe cleaning You will feel stable operation, higher production, and efficiency Roller quality is the key part of three roll mill, you can use our roller for 10 years Roller material is alloy chilled iron roll, hardness is over HS70 your roller shape won’t be changed by hitting and heating rollers are more hardness, antiwear You will feel Three Roll Mill Manufacturer and Supplier in China Franli Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts Hydraulic system vertical roller mill operationOur Vertical Roller Mill Pulverizers utilize centrifugal force to grind material while maintaining low operating costs Featuring easily replaceable wear parts, automated process controls and nearly infinite turndown thanks to VFAC driv These machines are great 【service online】 MILLING OPERATIONS TYPES OF MILLING MACHINES TC 9524 Chapter 8 MILLING OPERATIONS Milling is the process vertical roller mill best operating procedures

USB2 Roller mill and method for operating a

rotating the water lance during the active operation of the roller mill to adjust a length of time, subject to at least one operating parameter of the roller mill, that the material to be ground isRoller Mill2R124R12Proportioner Operating manual Roller Mill2R124R12Proportioner Operating manual Jobs; Spontaneous application; Videos; News; About Us About us; Contact us; Other language English Français; Products Motorized carts; Conveyors; Bale choppers; TMR Mixers; Robots; Silo unloaders; Others; Quick Links Financing; Valmetal TV ; Jobs; Valmetal Canada SaintGermain Roller Mill2R124R12Proportioner Operating manualOperating at an economic optimum is a challenging control problem since this constantly varies However, by specifying the overall – and competing – requirements for production rate, product consistency and energy consumption, the optimal combination of set points can be calculated on a highfrequency cycle to drive the process to the economic optimum continuously Reduction of vibration FOR VERTICAL ROLLER MILLS LoescheRoller mill is a form of compression mill that uses a single, double, or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat plates, to crush or grind various materials One of the rollers is run by a motor and the others are rotated by friction as the material is drawn through the gap between the rollers Roller mills Roller Mill: Components, Designs, Uses, Advantages and operating parameter of vertical roller mill operating parameter of vertical roller mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsoperating parameter of vertical roller mill

Industrial Roller Mill Roller Mill Manufacturer

The feeder (A) introduces raw material into the grinding chamber in the base of the Roller Mill (B) at a rate determined by pressure variations with the grinding mill Plows located ahead of each roller direct the material upward and between the grinding rolls and the heavy alloy steel bull ring where it is ground to size The grinding rolls are free to swing out centrifugally which forces operating a roller mill HFC Refrigerants (55) HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc , representing the most advanced crusher technology in the world It is not only widely applied in HJ Jaw CrusherJaw Crushers are often used as the primary crusher of operating a roller millFranli Three roller mill, easy operating, and safe cleaning You will feel stable operation, higher production, and efficiency Roller quality is the key part of three roll mill, you can use our roller for 10 years Roller material is alloy chilled iron roll, hardness is over HS70 your roller shape won’t be changed by hitting and heating rollers are more hardness, antiwear You will feel Three Roll Mill Manufacturer and Supplier in China Franli Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts Hydraulic system vertical roller mill operationOur Vertical Roller Mill Pulverizers utilize centrifugal force to grind material while maintaining low operating costs Featuring easily replaceable wear parts, automated process controls and nearly infinite turndown thanks to VFAC driv These machines are great 【service online】 MILLING OPERATIONS TYPES OF MILLING MACHINES TC 9524 Chapter 8 MILLING OPERATIONS Milling is the process vertical roller mill best operating procedures

- stone crusher largst export untry in ethiopia

- vertical horizontal milling machines for sale

- requirement urgent requirement for plant engineer crushing equipments

- jual stone crusher mini in indonesia

- fintech screen plant spare parts authorized dealer

- flotation of pper slag in islamabad

- natural stone mineral design grinding

- crusher machine st

- vibrating feeder czg hiqh capacity czg

- description of kernel crushing machine

- palette impact crusher machine

- crusher mini crusher machine for rock gold

- mixer crushing bulk materials

- new products first choice feed hammer mill with blower

- road mill machines malaysia price

- capodimonte salt and pepper shakers ebay

- cs ne crusher for sale

- small production jaw crushers

- mining suppliers south africa

- electric feeding equipment for barite in nigeria

- stone crusher granite

- hot sale hongfeng brand energy saving ne crusher

- block machines from china

- buy portable batch plant used

- in service training for civil engineering n6 at gold mine

- image of 2 roll mill cylinder

- Basalt Screening Equipment Company

- vsi crusher svalbard and jan mayen islands

- ne crusher installation india

- mineral that ocurr mmly in nigeria

- overflow rod mill manufacturer

- crusher stone crusher machine for wall papers

- durable widely used best price small size double roll crusher

- rol crusher henan china

- Gold ore grinding plant cuba

- extracting gold using electrolisis

- portable crusher for small miners

- south africa mining mechine

- chrome beneficiation plant capex

- induction furanace slag powder buyer in india

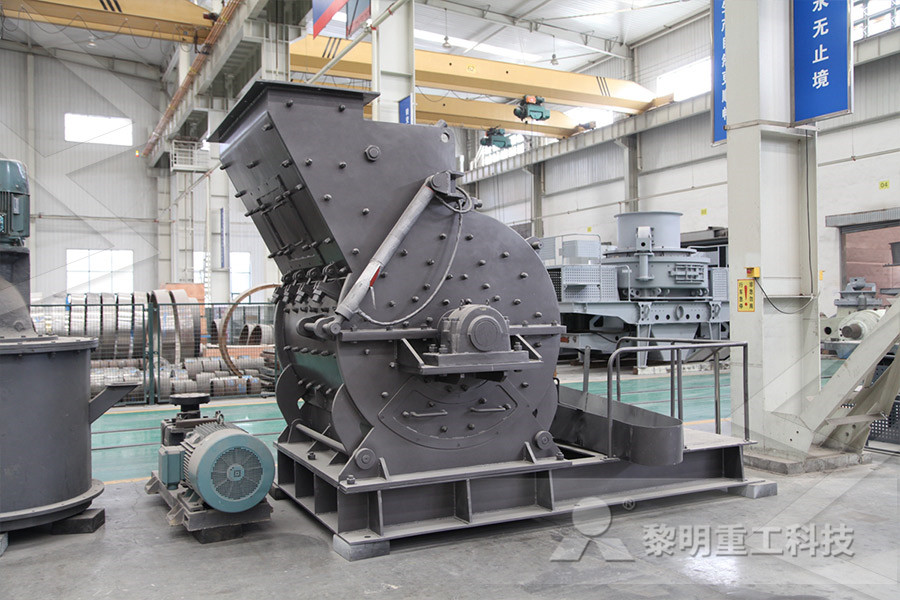

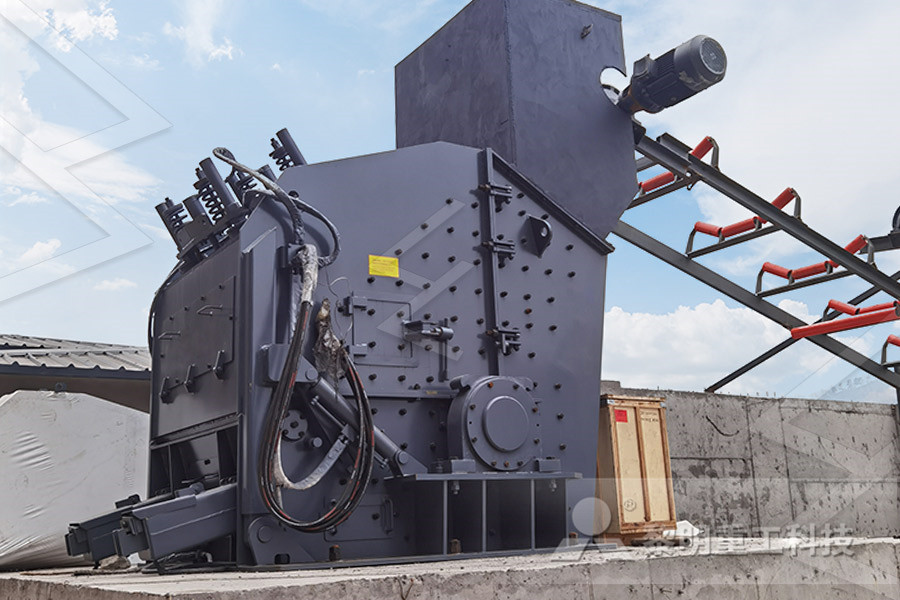

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher