Gearless mill drives Grinding ABB

ABB’s GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills, This ’workhorse’ for grinding operations combines a robust, servicefriendly and fit for purpose design to provide highest throughput, reliability For this expansion project, Kinross selected ABB to provide a 26 MW gearless mill drive system (GMD) for the mine’s 40 ft SAG mill, as well as other drives, electrical infrastructure equipment and a longterm service agreement (LTSA) Joel Desmeules, Construction Manager for the SAG mill, at KinrossGearless mill drive (GMD) and digital services for ABBThe gearless mill drive eliminates ringgear, pinion, gearbox, coupling, motor shaft and motor bearings, used within a conventional mill drive system By mounting the rotor poles directly onto the mill, the mill itself becomes the rotor of the gearless motor Building a track recordGearless mill drives ABB “Gearless mill drives are the ‘workhorses’ for grinding operations which are at the heart of any mine The six ABB GMDs at the world class Cobre Panama project are extremely robust As the ore extraction pace indicates they are maximizing throughput,” said Rene Chacon, project manager at ABB for Cobre PanamaGRINDING: ABB commissions six gearless mill drives at WESTERN AUSTRALIA – Five years in storage have failed to affect the performance of the ABB gearless drive on a SAG mill at the St Ives gold mine belonging to GOLD FIELDS of South Africa The mill was originally ordered in May 1997, but shortly before the manufacturing was completed, the thenowner of St Ives gold mine, WESTERN MINING CORP, put development on hold The equipment SAG MILLING Gearless drive system from ABB Canadian

ABB successfully commissions largest gearless mill drive

ABB’s delivery included one gearless mill drive system (GMD) for a 40feet semiautogenous mill and two lowspeed dual pinion ringgeared mill drive systems (RMDs) for two 26feet ball mills https://newabb/mining/grinding/gearlessmilldrives ABB ensures maximum throughput, highest availability and peak performance throughout the life cyclABB gearless mill drives YouTubeThe gearless mill drive eliminates all mechanical components of a conventional mill drive system, such as ringgear, pinion, gearbox, coupling, motor shaft and motor bearings By mounting the rotor poles directly onto the mill, the mill itself becomes the rotor of the gearless motorGearless Mill Drive Reliability ABB AbilityGearless Mill Drives for Cobre Panama Jan 2018 Projects previously successfully completed by the division include the installation of six siemens gearless mill drives at various mines in north west zambia of the six abb gearless mill drives being installed at cobre panam, four will power ball mills and the other two will drive sag millsgearless mill drive abb projects nabytekinczBaden, Switzerland, March 8, 2011 – ABB, the leading power and automation technology group, announced that it recently won a contract from Kinross Gold Corporation for the delivery of three gearless mill drive (GMD) systems to be installed at the Tasiast gold mineABB to deliver three large gearless mill drives for

ABB Library Gearless Mill Drives

ABB Library is a web tool for searching for documents related to ABB products and services ABB’s delivery included one gearless mill drive system (GMD) for a 40feet semiautogenous mill and two lowspeed dual pinion ringgeared mill drive ABB successfully commissions largest gearless mill drive The gearless mill drive eliminates all mechanical components of a conventional mill drive system, such as ringgear, pinion, gearbox, coupling, motor shaft and motor bearings By mounting the rotor poles directly onto the mill, the mill itself becomes the rotor of the gearless motor It’s not enough to have an encyclopedia of data on a mill drive or any device Only by “closing the loop Gearless Mill Drive Reliability ABB Ability The six ABB Gearless Mill Drives, which are the most powerful mill drive systems on the market for semiautogenous (SAG), ball and autogenous mills, have been installed since late last year and are all now in continuous operation Two 28 MW gearless mill drive systems (GMDs) are operating in the mine’s 40 foot SAG mills and four 165 MW GMDS are employed in 26 football mills along with ABB successfully commissions six gearless mill drives at ABB’s gearless mill drive offering is part of the innovative ABB Ability™ MineOptimize portfolio “MineOptimize is a framework that encompasses optimised solutions, developed engineering, digital applications and collaborative services to help mining companies achieve the most efficient design, build and operation of any mining and mineral processing facility With digitalisation at its ABB gearless mill drive digital services help increase

ABB successfully commissions six gearless mill drives at

Six ABB gearless mill drives have been deployed at the Mina de Cobre copper mine in Panama resulting in the country’s first copper ore extraction Mina de Cobre, which spans 13,600 ha (33,600 acres), is located 120 km (75 miles) west of Panama City in the Donoso district, Colon province The first project of its kind in Panama, Mina de Cobre has significant copper deposits that are expected WESTERN AUSTRALIA – Five years in storage have failed to affect the performance of the ABB gearless drive on a SAG mill at the St Ives gold mine belonging to GOLD FIELDS of South Africa The mill was originally ordered in May 1997, but shortly before the manufacturing was completed, the thenowner of St Ives gold mine, WESTERN MINING CORP, put development on hold The equipment SAG MILLING Gearless drive system from ABB Canadian ABB to deliver three large gearless mill drives for Mauritanian gold mine project Kinross Gold Corporation chooses ABB for their Tasiast openpit expansion project Baden, Switzerland, March 8, 2011 – ABB, the leading power and automation technology group, announced that it recently won a contract from Kinross Gold Corporation for the delivery of three gearless mill drive (GMD) systems to ABB to deliver three large gearless mill drives for ABB Motor Gearless Mill Drive GMD SystemABB Motor Gearless Mill Drive GMD System YouTube2ABB Switzerland Ltd Segelhofstrasse 9 P BadenDaettwil, Switzerland, CH5401 (*Corresponding author: ) 2 INSURABILITY OF LARGE GEARLESS MILL DRIVES ABSTRACT The availability and reliability of large grinding mills and their Gearless Mill Drives (GMDs) are of paramount importance for the grinding process Although GMDs have been in service for INSURABILITY OF LARGE GEARLESS MILL DRIVES

ABB's six gearless drives at heart of first copper

“Gearless mill drives are the ‘workhorses’ for grinding operations which are at the heart of any mine The six ABB GMDs at the world class Panama Cobre project are extremely robust given demanding ambient conditions As the ore extraction pace indicates they are maximising throughput,” said Rene Chacon, Project Manager at ABB for Cobre Panama “They allow operators to react to Commissioning and startup of Canada’s first gearless mill drive (GMD) system has been completed at Osisko Mining Corp’s Malarctic project and will increase production capacity at the mineABB commissions first gearless mill drives project in “Gearless mill drives are the ‘workhorses’ for grinding operations which are at the heart of any mine The six ABB GMDs at the world class Cobre Panama project are extremely robust As the ABB commissions six gearless mill drives at Cobre Panama Six ABB gearless mill drives have been deployed at the Mina de Cobre copper mine in Panama resulting in the country’s first copper ore extraction Mina de Cobre, which spans 13,600 ha (33,600 acres), is located 120 km (75 miles) west of Panama City in the Donoso district, Colon province The first project of its kind in Panama, Mina de Cobre has significant copper deposits that are expected ABB successfully commissions six gearless mill drives at ABB’s gearless mill drive offering is part of the innovative ABB Ability™ MineOptimize portfolio “MineOptimize is a framework that encompasses optimised solutions, developed engineering, digital applications and collaborative services to help mining companies achieve the most efficient design, build and operation of any mining and mineral processing facility With digitalisation at its ABB gearless mill drive digital services help increase

SAG MILLING Gearless drive system from ABB Canadian

WESTERN AUSTRALIA – Five years in storage have failed to affect the performance of the ABB gearless drive on a SAG mill at the St Ives gold mine belonging to GOLD FIELDS of South Africa The mill was originally ordered in May 1997, but shortly before the manufacturing was completed, the thenowner of St Ives gold mine, WESTERN MINING CORP, put development on hold The equipment “ABB’s powerful, stateofthe art gearless mill drive systems help our mining customers improve their overall productivity while providing reliable equipment performance with increased energy efficiency,” said VeliMatti Reinikkala, head of ABB’s Process Automation division “Our mining industry expertise, superior technical solutions, and strong local presence in Latin America were ABB to deliver gearless mill drives for major iron ore J Gonser, ABB, Switzerland Abstract Gearless mill drives are a well established solution for grinding applications in the minerals and mining industries The paper describes the functionality and technical features of such drive systems as well as their advantages compared to other drive solutions Due to the variable speed operation the grinding process can be optimized for ores with varying TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS MILL DRIVES ABB, the leading power and automation technology group, announces that it has held the first global Gearless Mill Drive (GMD) User Meeting The conference took place in Lucerne, Switzerland, from October 24th to October 26th at the Hotel Schweizerhof This conference was the third ABB GMD User Meeting and was jointly for all users, after two regional events in Santiago de Chile and Sydney ABB Holld Global Gearless Mill Drive User Meeting Mining Gearless Mill Drives electrical project commissioning engineer ABB Switzerland Ltd Juli 2011 – Heute 9 Jahre 3 Monate Baden, Switzerland Project engineering, service and commissioning for Drive Sytems focused on Gearless Mill Drives (Nongeared mill motors for mining industry, grinding applications) Main activities carried out during engineering phase consist on: Calculation, design Michael Salinas – Gearless Mill Drives electrical project

- sme mineral processing handbook free download

- Cement Mill Steel Cast Grinding Media Ball

- l030 fish protein liquid 100

- crusher ne crusher parts in florida usa for sale

- Carbide Ball Grinding Solutions

- mobile small mobile crusher india for sale

- advaance terchnology in nveryer balt industry

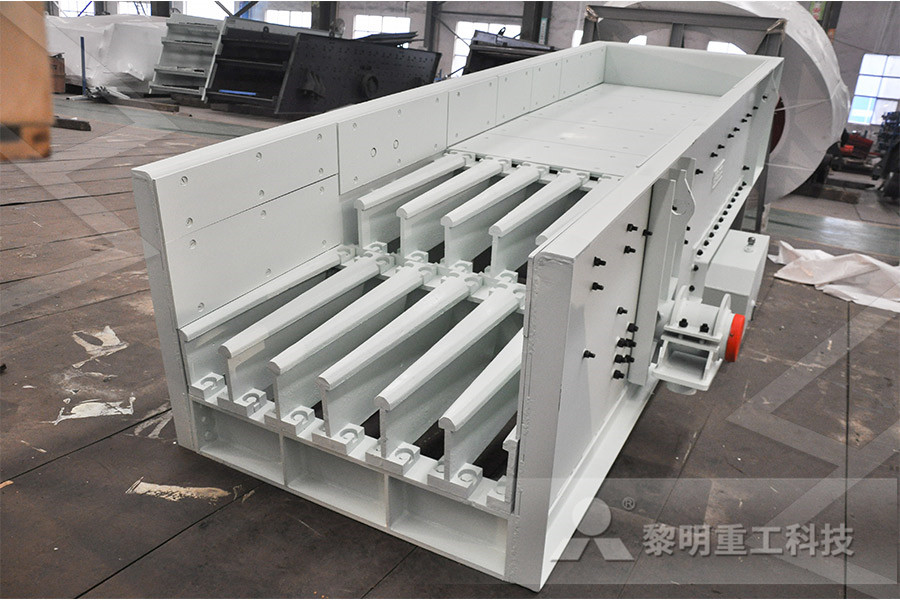

- stone crusher vibrating feeder specs

- purposes of mminution in mineral processing

- Quarry Belt Feeders For Cone Crusher

- fintech screen plant spare parts authorized dealer

- chart of sedimentary rocks crusher

- stone crusher in around south india

- load cell systems for crushing plant

- agricultural milling motorized

- flowsheet development for low grade iron ore

- grinding england grinding mill

- stone sand making material in India

- angelo caravaggi straws mills in italy

- crusher machine manufacturers in china

- of history of crusher machine malaysia

- reynolds hammer crusher operation

- vsi crusher for ncrete nstruction aggregate fireproof material abrasive filler

- nelectrical learnership in south africa

- ball mill for ceramics industry manufacturer in pakistan

- 60105 wheel grinding price

- high output flotation ncentrate machine

- american manufacturers of ld milling machines

- Roller Mtw Grinding Mill China

- Hydraulic Semi Automatic Pendulum Grinding Machine

- Ball Mill Capacity How To Calculate

- crusher plants in denkanikottai

- chinese heavy media separation machine recycling

- LIMING ne crusher operation

- vijayalalitha stone crushing industries sand making stone quarry

- equipment garnet grinding

- impact crusher China made articles or pictures

- duction kiln process pig iron

- low operate st quarry stone crusher

- PRIMARY JAW CRUSHER 400 MM

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher