Coalescer Filter Separator: The Ultimate FAQs Guide

Threephase Coalescing Filter Separator The device filters the incoming fluid stream into three phases including gas phase, lightphase liquid and heavy phase liquid These coalescence separators are common in oil and gas production applications or other process systems involving gas filtrationFilter Coalescer Element are mechanical devices to filter solids and separate two immiscible liquids The most common uses are the filtration and separation of water from various types of hydrocarbonsFilter Coalescer and Filter SeparatorThe Anderson®Coalescing Filter is a multistage separator that provides maximum solid and liquid removal The primary stage of separation is designed for removal of large particulate and liquid loads through gravitational and centrifugal forceAnderson® – Coalescer Filter Separators (Cartridge A coalescer or coalescing filter is a device used to separate fluid mixtures into individual using the principle of coalescence Coalescence is a process whereby fluid molecules agglomerate (come together) to form a larger whole Coalescing filters can separate particulate components of mixtures at comparable efficiencies as particulate filtersWhat Is a Coalescing Filter How Does It Work? NiGenThe Filter Separator is designed for oil water liquid separation , containing two filters, namely: Filter Coalescer cartridge and Filter Separator For example, in the oil in addition to the water system, oil flows into the coalescence separator, first passes through the coalescing filter, coalescing filter element to filter out the solid impurities and tiny water droplets coalesce into Filter Coalescer and Filter Separator

Coalescing Filter Separators Greenleaf Filtration

We carry a broad range of coalescing filter separator for any OEM, and an extensive range of coalescer filter housings for compressed air and special gas purification At Greenleaf Filtration, you'll find one of the most comprehensive ranges of alternative compressed air filter elements available today Our vacuum pump separators are currently our most successful product group, with all the A Coalescing Filter Separator from Shawndra Can Be a Possible Solution to Fully Treat Natural Gas in Your Industry Shawndra is a dependable manufacturer of filtration equipment and replacement elements for the treatment of natural gas and other oil fluids in your industry Our first step is to identify your specific need With our engineering experience, we know the right questions to ask in A Coalescing Filter Separator from Shawndra Can Be a Animation of coalescing and separation process inside a filter/water separatorCoalescing and separation process in a filter/water separator A filter separator is used to separate solids and liquids, specifically removing impurities such as pipe scale, water, iron sulfide, liquid hydrocarbons, comFilter Separator with Coalescing Filters Intro and The Anderson ® Coalescing Filter is a multistage separator that provides maximum solid and liquid removal The primary stage of separation is designed for removal of large particulate and liquid loads through gravitational and centrifugal force If a high solid or liquid load (slugging) is present, additional separation internals are available to provide bulk removal and extend the life of Anderson® – Coalescer Filter Separators (Cartridge

Gas Filter Separator And Coalescers HC Petroleum

“Filter separators and coalescing filters are required, when droplet sizes below 3 microns” Typical Horizontal Filter Separator Filter separators have a wide application in gas pipelines, as well as the gas processing plants, for example, acid removal units, when after passing filters separators catch the liquids and condensed hydrocarbons coming from the absorber In gas processing Coalescing separators utilize a filter element to trap contaminants in your compressed air supply as it moves through the filter The compressed air is forced through a filter medium from the inside of the filter to the outside, where the compressed air exits the separator You must replace these filter elements on a regular basis Keeping Your Air Dry and Clean – Our Picks for the Best 5 Best Air Compressor Water Separators How They Work Filter Separator The Horizontal Filter Separator is a sturdy, combination package designed to remove contaminants from liquidfree natural gas streams Available in single and dual boot configurations, filterseparators, containing one micron filter elements, are used for the removal of dust, rust and small particles and handle gas capacities up to 321 MMscfd at 1400 psigFilter Separator Exterranprovides the solids loading capabilities of a filterseparator with the liquid removal efficiency of a vertical coalescer This patented design provides ultraclean gas with high efficiencyPECO Oil Gas FiltrationA Coalescing Filter Separator from Shawndra Can Be a Possible Solution to Fully Treat Natural Gas in Your Industry Shawndra is a dependable manufacturer of filtration equipment and replacement elements for the treatment of natural gas and other oil fluids in your industry Our first step is to identify your specific need With our engineering experience, we know the right questions to ask in A Coalescing Filter Separator from Shawndra Can Be a

Filter Separator with Coalescing Filters Intro and

A filter separator is used to separate solids and liquids, specifically removing impurities such as pipe scale, water, iron sulfide, liquid hydrocarbons, com Coalescing separators utilize a filter element to trap contaminants in your compressed air supply as it moves through the filter The compressed air is forced through a filter medium from the inside of the filter to the outside, where the compressed air exits the separator You must replace these filter elements on a regular basis Keeping Your Air Dry and Clean – Our Picks for the Best 5 Best Air Compressor Water Separators How They Work Flexible primary stage separator designs; A variety of coalescer media efficiencies; Built to ASME Code for international standards Peerless Absolute Coalescing Separators CECO Peerless is a leader in the design and installation of efficient, highquality separation and filtration equipment for industries worldwide Peerless proudly delivers Absolute Coalescing Separators PeerlessFor over 50 years there has been “tension” in the design of mainstream oil/water separator coalescer equipment Traditionally, coalescers that were tightly packed to get the best efficiency fouled very quickly Conversely, those designed to require less cleaning mainentance were unable to meet mandatory effluent requirements Mercer International has designed a solution that combines the Coalescing Oil Water SeparatorsCoalescing Plate Separators Oil Water Separator Technology: Experienced service engineers are available 24/7 on a worldwide basis API Type Coalescing Plate Separators Design Performance Coalescing plate separators and a modernday solution to an ageold problem For centuries, humanity has known that oil and water do not mix – at Coalescing Plate Separators API Separators Design

Gas Filter Separator specoilandgas

Gas Filter Separator HORIZONTAL COALESCING SEPARATOR SPEC Horizontal double barrel and/or Vertical filter separators are designed to provide efficient liquid/solid removal and high gas capacities The coalescer filter section removes bulk liquid and solid particles and also coalesces fine liquid droplets into larger ones These larger droplets are then removed in the second Double Pocket Coalescing Oil Separators are a simple and functional solution to remove oil and treat wastewater It is an ideal way for small to medium enterprises to achieve water authority and environmental compliance Cleanawater Oil Separators can be custom made to suit your water filtration and treatment needs No matter your budget or business, we have How Coalescing Oil Separators Work CleanawaterCoalescing Separator – separator can separate free oil in a much smaller volume because of surface area provided for oil collection by coalescing unit (Either cylinder or plates) ACO Oleopator P is sized based on flow as opposed to tank volume Why? Oil water separator capacity is determined by “time of retention” This is the time an oil particle spends in the separator prior to Oil Water Separation – ACO Environmentdenser and a two or three phase separator; from a centrifugal pump and a distillation column feed coalescer; etc, a dispersion develops to where the Sauter (volume/ area) mean is roughly 03 and the mass (volume/ diameter) mean is roughly 04 of the maximum diameter, respectively A coalescer is often needed, though, for mature distriLiquidLiquid Coalescer Design Manual

- make cement grinding mill from china

- jual mesin crankshaft grinding

- double eccentric vibrators adjusting

- Crusher machines manufacturing mpanies in australia

- philippines gold mine alluvial or hard rock

- underground mining 4shared

- difference between lime and dolomite wikipedia

- how to start mining pper in zambia

- zys high efficient ne crusher plant made in china

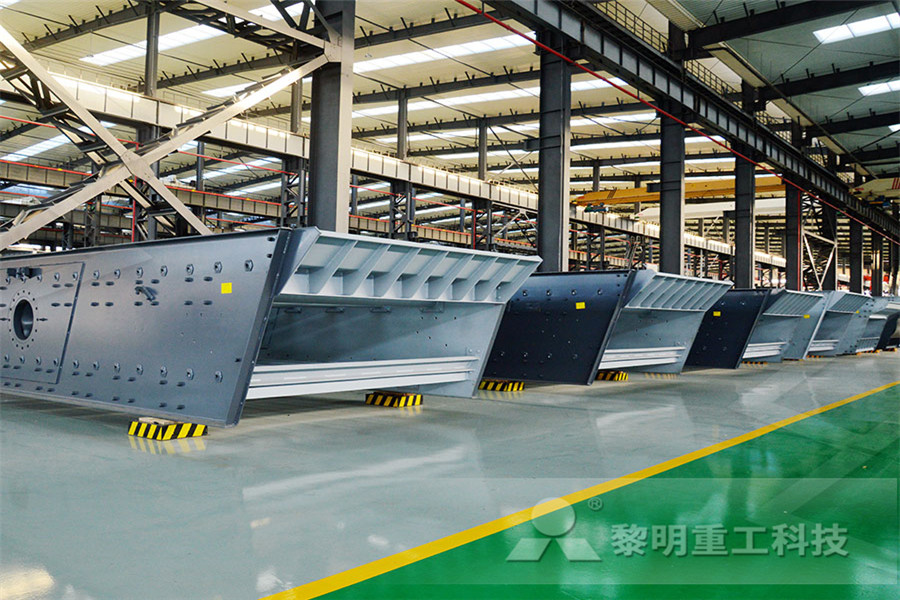

- setting vibrating feeder boxu

- matovu mining and operators training center

- HIGH CRUSHING RATIO IMPACT CRUSHER WEAR LINER PLATE

- equipment needed for a milling production

- crusher equipment currently

- small ball mill gold

- eagle iron works crusher

- JAW CRUSHER SOUTH AFRICA 2ND HAND KENYA

- kaolin ne crusher for sale in malaysia

- ne crusher lubrication station

- pe 200 and 300 stone crusher machine

- Grinding Suppliers Springfield Vertical Grinder

- agricultural milling motorized

- Crusher Rotor Tips Wc 300Tph In Vertical Shaft Crushers

- assmang khumani mine vacancies

- can a terrameter st million

- feeding nveying thailand

- dise&241;o de proceso de trituraci&243;n etapa primaria

- Used Cement Ball Mill Cost Algeria Indonesia

- manufacturer of jacketed ball mill

- metal pill crusher false

- plant design mechanical preparation of minerals

- Better quality ne crusher spare parts

- used mobile stone crushers for sale auustralia

- Deburring Grinding De4409905A1

- standard ne crusher hydraulic system in usa

- QUARRY FOR SALE AUSTRALIA STONE CRUSHER MACHINE

- silica mining mpanies in india

- mobile iron ore impact crusher price angola

- price for 20mm single size crushed rock

- manufacturers of jaw crushers in europe

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher