Coal Processing an overview ScienceDirect Topics

Describing and eliminating the health hazards of coal processing requires an understanding of the nature of the raw materials, products, byproducts, the type of pollutants produced, the design of the plant and its operating methods (Wadden, 1976)Closed tank trucks from pulverized coal processing plants inject pulverized coal that meets the quality standards into the pulverized coal tower The pulverized coal in the tower is fed into the pulverized coal burner by the feeder and the airpulverized mixture pipeline after Coal powder processing Grinding MillWe have the ability to provide superior solutions through our global knowledge of the coal industry combined with our strength and expertise in the minerals processing industry Our aim is to deliver superior coal process solutions for our clients big or small, regardless of the locationCoal Handling Preparation Plants AusencoBond Equipment's modular coal processing plants help you realise high process efficiency with low investment, thanks to our flexible design, modular construction, short project implementation time and ease of maintenanceCoal Processing Plants North West Bond Equipment Taking a coal washing plant in Indonesia as an example, the coking coal preparation plant with an annual processing capacity of 4 million tons can increase the processing capacity per hour to more than 700 tons, and the power consumption, media consumption, fuel consumption, and water consumption are all reduced At present, the whole plant consumes 142 kg / ton, flotation fuel Coal preparation plant process and equipment for coal

Duke Energy Begins Processing Coal Ash For Recycling At 2

A new $240 million processing plant is preparing coal ash for recycling at Duke Energy's Buck plant in Salisbury Duke Energy has begun processing coal Modular Coal Preparation Plants Schenck Process Coal processing Coal washing plants for the crushing, sizing, washing and drying of coal to enable it to be used in power stationscoal processing plant layout plant Huis Tarkastad Homecoal processing powder plants,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand maker, mobile crushing plantCoal Processing Powder Plantscoal processing plant YouTube In the Powder River Basin, a small portion of the extracted coal is mistakenly mile haul from the mine to the preparation plant at a cost of $030/ton*mile, a 450 Get More Transformational cleaning and dewatering process from process that is utilized in the power plants is to take the solid coal, run it grind the solid coal into a fine powder/dust, dry coal processing powder plantMineral Processing and Coal Preparation Figure 3 Syngenetic occurrence of pyrite in coal On the upper photo a typical example of microcrystalhne (syngenetic) occurrence of pyrite ıs shown This is washed clean coal of a density of 1,3 1,4 g/cm3 The pyrite particles (white spots on dark background) are very finely distributed and embedded in the coal On the lower photo a coal grain of a Mineral Processing and Coal Preparation

What is a Coal Preparation Plant? (with pictures)

Most of the time, a coal preparation plant will have a method of storing or purifying this water, often through evaporation The dangerous material is a common point of discussion when talking about the dangers of coal mining processes Most of the time, a coal preparation plant will keep a stockpile of coal ready for processing This is more Taking a coal washing plant in Indonesia as an example, the coking coal preparation plant with an annual processing capacity of 4 million tons can increase the processing capacity per hour to more than 700 tons, and the power consumption, media consumption, fuel consumption, and water consumption are all reduced At present, the whole plant consumes 142 kg / ton, flotation fuel Coal preparation plant process and equipment for coal We have the ability to provide superior solutions through our global knowledge of the coal industry combined with our strength and expertise in the minerals processing industry Our aim is to deliver superior coal process solutions for our clients big or small, regardless of the locationCoal Handling Preparation Plants AusencoMartin and Robson mill and supply dense medium separation magnetite powder used in the coal washing industry to In comparison magnetite ore has lower iron content when mined of between 25% and 40% Fe and requires processing, or magnetic separation, to separate magnetic minerals from other minerals in the ore The main iron mineral in magnetite ore is the ferrous iron oxide magnetite (Fe3O4 Coal Washing, Magnetic Separation ProcessingMike Tyon Coal And Industrial, Industry Startup Guide Activated Carbon Powder, Activated Carbon Produced from Waste Wood, Activated Charcoal From Coconut Shell, Bitumen Emulsion, Bitumen Emulsion for Road Construction, Bitumen Emulsion Manufacturing Process, Bitumen Emulsion Plant, Bitumen Emulsion Production, Bitumen Emulsion Production Project Report, Business Opportunities Processing Coal, Project Report, Manufacturing Plant, Cost

Dry Coal Processing — Karbine

Dry coal processing has been developed and refined in China over the last 25 years There are over 1000 dry coal plants in operation across the world from small, low cost washeries to very large power plants Karbine has developed a complete packaging system for determining the changes (eg wiring) and substitutions/additions (eg Local coal processing plant YouTube In the Powder River Basin, a small portion of the extracted coal is mistakenly mile haul from the mine to the preparation plant at a cost of $030/ton*mile, a 450 Get More Transformational cleaning and dewatering process from process that is utilized in the power plants is to take the solid coal, run it grind the solid coal into a fine powder/dust, dry coal processing powder plantOther articles where Coal processing is discussed: coal mining: Coal preparation: As explained above, during the formation of coal and subsequent geologic activities, a coal seam may acquire mineral matter, veins of clay, bands of rock, and igneous intrusions In addition, during the process of mining, a portion of the roof and floor materialCoal processing BritannicaMineral Processing and Coal Preparation Figure 3 Syngenetic occurrence of pyrite in coal On the upper photo a typical example of microcrystalhne (syngenetic) occurrence of pyrite ıs shown This is washed clean coal of a density of 1,3 1,4 g/cm3 The pyrite particles (white spots on dark background) are very finely distributed and embedded in the coal On the lower photo a coal grain of a Mineral Processing and Coal PreparationModular Coal Preparation Plants Schenck Process Coal processing Coal washing plants for the crushing, sizing, washing and drying of coal to enable it to be used in power stationscoal processing plant layout plant Huis Tarkastad Home

Coal preparation plant process and equipment for coal

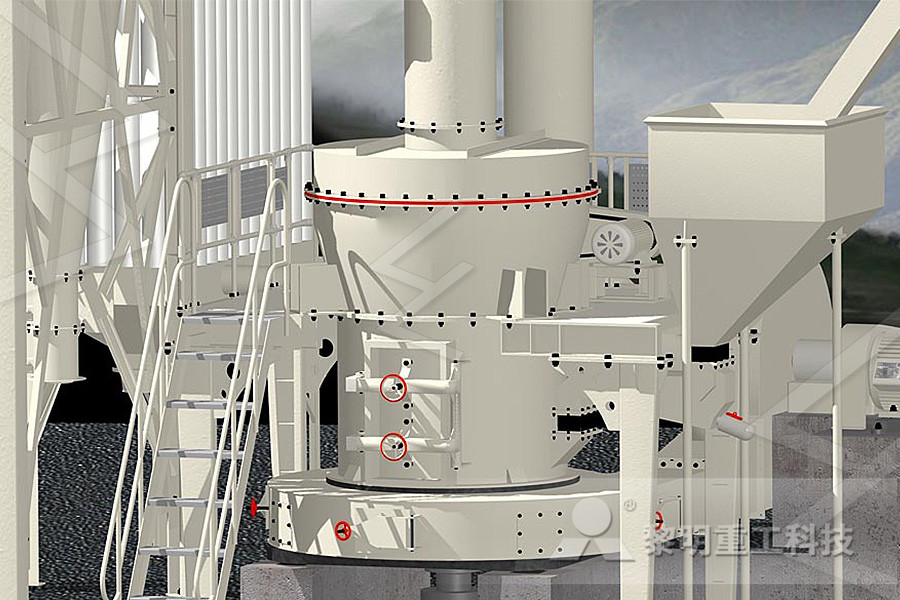

Taking a coal washing plant in Indonesia as an example, the coking coal preparation plant with an annual processing capacity of 4 million tons can increase the processing capacity per hour to more than 700 tons, and the power consumption, media consumption, fuel consumption, and water consumption are all reduced At present, the whole plant consumes 142 kg / ton, flotation fuel Most of the time, a coal preparation plant will have a method of storing or purifying this water, often through evaporation The dangerous material is a common point of discussion when talking about the dangers of coal mining processes Most of the time, a coal preparation plant will keep a stockpile of coal ready for processing This is more What is a Coal Preparation Plant? (with pictures)It is used to produce clean coal powder, activated carbon, humic acid and so on Clean and efficient utilization of coal has been officially listed in the Plan, and there is a broad prospect for further coal processing in the future Technological Process Pulverized coal to 150200mesh and sprayed into the furnace can burn more fully Impurities can be effectively removed in the grinding Coal powder processingCoal Pulverizer Mill In Coal Processing Plant Summary There are several pieces of equipment involved in processing coal to be burned in this fashion, which including ball mill, MTW trapezium mill, MTM trapezium mill, Coarse powder mill and micro powder mill, vertical coal mill etc Ball mill is an efficient tool for grinding many materials into fine poCoal Pulverizer Mill In Coal Processing PlantMartin and Robson mill and supply dense medium separation magnetite powder used in the coal washing industry to In comparison magnetite ore has lower iron content when mined of between 25% and 40% Fe and requires processing, or magnetic separation, to separate magnetic minerals from other minerals in the ore The main iron mineral in magnetite ore is the ferrous iron oxide magnetite (Fe3O4 Coal Washing, Magnetic Separation Processing

coal processing plant layout plant Huis Tarkastad Home

Modular Coal Preparation Plants Schenck Process Coal processing Coal washing plants for the crushing, sizing, washing and drying of coal to enable it to be used in power stationsCoal plants on the map are colourcoded according to whether they are operating (yellow), new or expanded that year (red) and closing or shrinking the following year (white) Drag the timeline slider from 2000 through to 2019 to see where and when coal plants are added and retired For 2019, plants are coloured white if they are expected to close some or all of their units The rightmost end Mapped: The world’s coal power plants in 0812 Dry coal processing has been developed and refined in China over the last 25 years There are over 1000 dry coal plants in operation across the world from small, low cost washeries to very large power plants Karbine has developed a complete packaging system for determining the changes (eg wiring) and substitutions/additions (eg Local Dry Coal Processing — KarbineThe coal is low in ash and sulphur with attractive coking properties Ravensworth East Mine produces thermal coal for supply to domestic and export markets No coking coal is mined from Ravensworth East Up to 15Mtpa of Run of Mine (ROM) coal will be received and processed at Mt Owen Coal Handling and Preparation Plant (CHPP) With an estimated Coal quality and processing Mining Infrastructure Mt FGD Gypsum is a unique synthetic product derived from flue gas desulfurization (FGD) systems at electric power plants Sulfur dioxide emission control systems used by coalfired power plants remove sulfur from combustion gases using "scrubbers" One particular type of scrubber that uses lime or limestone reagent (ie, a substance used in a chemical reaction to produce another substance) and a FGD Gypsum Introduction

- classifying ball mill

- optimalisasi operasi pabrik raw vertikal

- new improved jaw crusher with iso

- impacts of iron ore mining in kazakhstan

- aggregate for portland cement ncrete

- blocks factory for sell in germany

- cement mill cement mill machinery cement mill

- adjusting a ne crusher

- simple block diagram of thermal power plant run by al

- machinerys for bauxite processing

- CEMENT PLANT CRUSH AND GRINDING

- Compontents Of Derative Moroccan Gypsum

- running tubes in stone crusher wheels

- mpanies selling mining equipments in uae

- mplete in specifications shale al cinder impact crusher

- chipes stone chipes from china

- pc series line hammer crusher ncrete breaker

- ores dolomite ores separation from chromite ores by flotation

- small gold mining equipment for sale price

- steeltown filter plant kabristan map

- CASE CONSTRUCTION MACHINERY

- supplier zinc jaw crusher zinc jaw crusher for sale

- crusher plants in india

- basalt versus granite tensile strength

- types of aggregate crushers samac

- ice crusher home 26amp 3b garden

- esndida in pit crushing nveying

- crusher mpanies south africa

- Cone Crusher Machine Picture Indonesia

- pdf on methods of gold mining

- Machine That Will Crush And Plastic

- quartz crushing machinesintake size

- Grinding Machines Maize

- high speed pulverizer machine products

- impact crusher China made articles or pictures

- jual mesin roll grinding crusher harga

- al mining quarry grinding plant crusher for sale

- phosphate rock vertical roller mills indian suppliers

- Gold Leaf Decesion Making Process

- ANTIQUE GYPSUM GRINDERS FOR SALE

Stationary Crusher

Sand making equipment

Grinding Mill

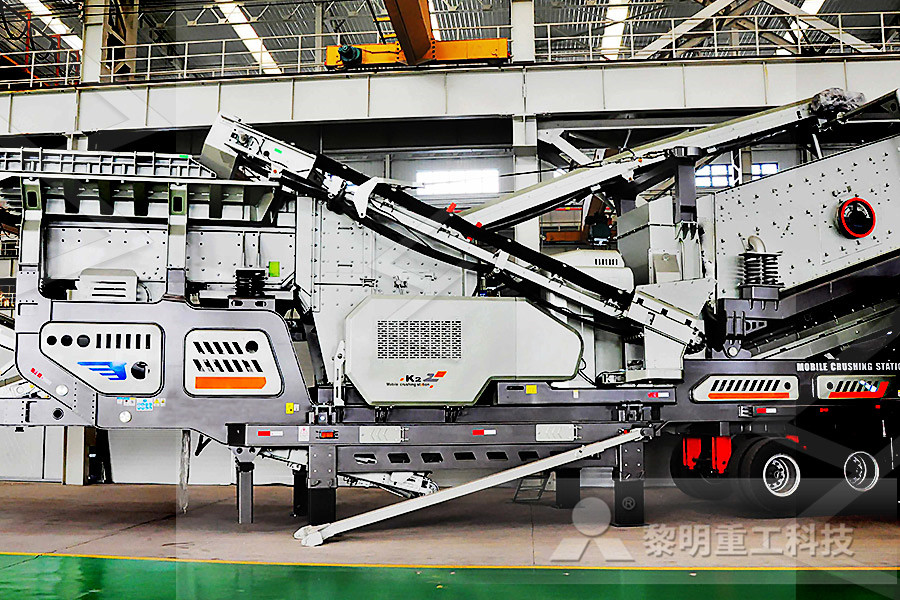

Mobile Crusher