Design fundamentals of sedimentation tanks CivilDigital

Design fundamentals of sedimentation tanks What is sedimentation and sedimentation tank??? Sedimentation is a process used for various stages within a wastewater treatment plant to reduce the concentration of settleable and suspended matter Sedimentation tanks, commonly referred to as clarifiers, are described as primary, intermediate and final clarifiers To design Sedimentation tank following elements are required in the consideration: Over flow velocity Detention period Flow through velocity Dimensions of the tank Sludge zone depth EfficiencySedimentation Tank Design Parameters The Constructor Water from a construction site must be treated in a sedimentation tank before it can be sent to the sewer This prevents solids like sand and grit from getting in the sewer, settling, and blocking the flow A sedimentation tank, also called a settling tank, holds the water and allows the solids to settle out before the water is released to the sewer Facilities that send solids to the sewer are liable for any Minimum standards for sedimentation tank design King CountyAny practical with a velocity lower than VP = Q/A will not removed in an up flow tank, but will escape in the effluent In a horizontal flow tank assuming that such particles were uniformly distributed to the flow, particle with Vp=Q/A still be removed in proportion Square sedimentation tank They may be flat bottomed or hopper bottomed Wastewater enters the tanks, usually at the center, through a well or Types of Primary Sedimentation Tanks Rectangular hi dears! Eid mubarak! today in this lecture we will be learning the detail design of a rectangular sedimentation tank or settling tank settling or sedimentRectangular sedimentation tank design YouTube

Plain sedimentation tanks ,Types Design considerations

Plain sedimentation tanks Theory design types of tanks By : ANSHIKA SAXENA BTech (FPE) INDIAN INSTITUE OF FOOD PROCESSING TECHNOLOGY TAMIL NADU 2 Sedimentation • The process of settling or being deposited as a sediment • Physical water treatment process • Uses gravity to remove suspended solids from water 3 Sedimentation tanks Waste water Abstract The present practice for the design of primary settling tanks is based on the overflow rate corresponding to the percentage removal using isoremoval plots The design procedure (PDF) Design of ClassI Sedimentation Tanks Types of Sedimentation Tanks based on Location Primary Sedimentation Tank Primary sedimentation tank is a normal sedimentation tank in which water is stored at rest for some time and sludge collected at bottom and oily matter collected at top are removed After primary sedimentation process the wastewater is discharged into aerobic filter Types of Sedimentation Tanks used in Water TreatmentThe design of a sedimentation pond can be a challenge as design parameters are difficult to define (eg, storm events, runoff, soil erodibility and distribution of erodible soil) Thus, the evaluation of the effectiveness of pond performance is difficult to quantify120 GUIDELINES FOR THE DESIGN OF SEDIMENT CONTAINMENT Solution for Design a sedimentation tank used for a surface overflow rate of 16 m/day to treat a flow of 625 m3/hr having detention time of 120 minutes ProvideAnswered: Design a sedimentation tank used for a bartleby

Sedimentation and the Design of Settling Tanks Semantic

Corpus ID: Sedimentation and the Design of Settling Tanks @inproceedings{Camp1946SedimentationAT, title={Sedimentation and the Design of Settling Tanks}, author={Thomas R Camp}, year={1946} }The simplest method of sedimentation is to use rectangular tanks with horizontal flow through them The water with the particles in suspension is introduced at one end of the tank, then as the water flows to the other end of the tank settlement of particles in the water occursSedimentation Processes IWA Publishing Design of Sedimentation Basins Introduction Sedimentation is a solidliquid separation that utilizes gravity to remove suspended solids used in water and wastewater treatment These suspended solids, or particles, are important to remove from water for several reasons Some of these reasons include: visibility impairment (aesthetic safety reasons), disease transmission (bugs attach WATER: Design of Sedimentation BasinsA CFD methodology for the design of sedimentation tanks in potable water treatment Case study: The influence of a feed flow control baffle A M Goula, M Kostoglou, +1 author A Zouboulis Published 2008A CFD methodology for the design of sedimentation tanks in sedimentation by in uencing velocity pro les However, further detailed experimental study is necessary to fully capture the ba e e ect and obtain further insight into the complex ow eld in a sedimentation tank Keywords: ADV; Intermediate ba e; Sedimentation tank; Primary settling tank; Reverse ow region INTRODUCTION Sedimentation by gravity is a usual and important process in settling tanks EXPERIMENTAL INVESTIGATION OF BAFFLE EFFECT ON THE FLOW

Design of Water Treatment Facilities

To cope with inexperienced operators, even if a rapid sand filtration process is a must, a treatment plant can be designed without complex mechanical facilities: eg a zigzag flow flocculation basin in place of mechanical flocculators; and automatic flow control filters instead of ones with flow regulators and backwash pumpsTy pically, primary sedimentation tanks are designed for effluent weir loading rates of less than 190 m 3 /day per meter of length of the weir (5,000 gpd/ft) T able 2 Key Design Criteria For (PDF) Introduction to Wastewater Clarifier DesignThe raceway design is a rectangular tank through which the water current flows from the inlet, placed at one end, to the outlet that is placed at the opposite end Its hydraulic efficiency is satisfactory, provided that dead zones and stratification are avoided by adjusting the water inflow and aeration To prevent circular eddies which could accumulate waste and debris in the centre, the PART 1 HATCHERY DESIGN AND CONSTRUCTIONConservation considers the Guidelines for the Design, Construction and Operation of Water and Sewerage Systems as an integral part of its regulatory program directed at ensuring public health and environmental protection This document supersedes April 1980 version of the “Guidelines for the Design, ConstructionGuidelines for the Design, Construction andIn the design of such tanks detailed attention has to be given to the inlet and outlet ends so that the water flows from one end to the end as uniformly as possible Partly because rectangular tanks have a large footprint, multilayer tanks (ie two or three decks) have been built These tanks are usually multipass in that the water flows along the length of one layer before returning along Sedimentation Processes IWA Publishing

A CFD methodology for the design of sedimentation tanks in

Abstract Computational fluid dynamics simulations are employed to assess the effect of adding a vertical baffle at the feed section of a fullscale sedimentation tank for the improvement of solids settling in potable water treatment A general CFDbased simulation strategy is developed based on the specific features and conditions met in practice for potable water treatment Moreover we would like to study the use the LES model in the flow and sedimentation modelling 2 Computational fluid dynamics modelling The longitudinal sedimentation basin being investigated is a real tank as in Fig 1 Due to contractual reasons, the tank will not be identified and its location is undisclosable While the k–ɛ model is probably the commonest turbulence model in Largeeddy simulations of particle sedimentation in a Sedimentation tanks are used in the process industry to separate the solid particles from the slurry to get the clarified liquid A detailed study of the hydrodynamics of sedimentation tanks is (PDF) Modeling Sedimentation in Underground Stormwater Primary Sedimentation Tank: 1 train (50mw x 130ml x 30mh x 10 tanks (20 waterways) Aeration Tank: 1 train (105 mw x 280 ml x 55 mh x 10 tanks) Final Sedimentation Tank: 1 train (50 mw x 260 ml x 35 mh x 10 tanks (20 waterways)) Disinfection tank: 50 mw x 27o ml x 50 mh x 4 waterways HRT (50 x 270 x 50 x 4)/141,000 x 24 x 60 = 27 Chapter 8 WASTEWATER TREATMENT PLANT CONSTRUCTION (PACKAGE E) The main aim of the present paper is to investigate the 2D hydrodynamics and flow behavior of a rectangular sedimentation tank with two configurations: one with a system of inclined parallel plates (lamellar settlers) and another with a conventional design, in order to evaluate the influence of lamellar settlers in the process efficiency This was achieved using the computational fluid The influence of lamellar settler in sedimentation tanks

(PDF) Introduction to Wastewater Clarifier Design

Ty pically, primary sedimentation tanks are designed for effluent weir loading rates of less than 190 m 3 /day per meter of length of the weir (5,000 gpd/ft) T able 2 Key Design Criteria For Its rate of sedimentation (v) is then given by v = dr/dt = 2r 2 p (ρ pp m)ω 2 r = 9η It is evident from this equation that the sedimentation rate of a given particle is proportional to its size, to the difference in density between the particle and the medium and to the applied centrifugal field It is zero when the densities of the Basic Principles of Sedimentation and Sedimentation Design Examples Design Example of Conventional Activated Sludge Process An activated sludge Use an hourly peaking factor of 4 for sizing the sedimentation facilities Select the type of package plant and size the principal components of the plant Effluent BOD 5 concentration of the process must be or lower than 30 mg/L Solution The total number of person : (550 home)(29 person Design ExamplesConservation considers the Guidelines for the Design, Construction and Operation of Water and Sewerage Systems as an integral part of its regulatory program directed at ensuring public health and environmental protection This document supersedes April 1980 version of the “Guidelines for the Design, ConstructionGuidelines for the Design, Construction and

- electric small electric powered jaw crushers from spain

- Coal Processing Plant In Malaysia

- vibrating screen classifieds

- How To Start A Small Gold Placer Mining Operation

- project report of cement interlocking icks

- mylar tubing wholesale

- st of refining gold

- ncrete crusher at engineering open house

- aac plant manufacturer germanyaac production line germany

- sch algerie nstruction machine bitou fer roue

- new rock phosphate mining projectrajasthanbrazil

- chinese ne crushers chinese ne crushers manufacturers

- high tensile strength jaw plate for stone crusher industries

- list suppliers of mine planning

- Granite Quarry Bengaluru Karnataka

- manufacturing process of tiles slideshare

- nsumption of grinding media in cement

- vibrating screen sand and gravel

- work place safety tips for cement factory

- industrial sand screening machine in india

- COAL CRUSHER MACHINE OPERATION

- new impact crusher for sale

- double stage Hammer Crusher CM42alibaba

- governor kenya ministry of minerals testing gdhk

- mpare Cost Algerias on ice cube crusher

- machine crusher machine for sale in ethiopia

- belt nveyor system manufacturers in india

- mcl grinding unitssalem

- project sales project manager india equipment

- flotation of pper slag in islamabad

- rubber and plastic mixing mill rfq

- britador br grinding

- lightweight ore mining machine

- ore dressing professional mine agitation tank

- Combination Crusher Equipment Has A Bright Prospect

- parts manual for crushing plant

- ball mill for chemical laboratory in india

- barrel crusher qualitybarrel crusher suppliers

- high pressure millibars

- stone crusher machine price small producers

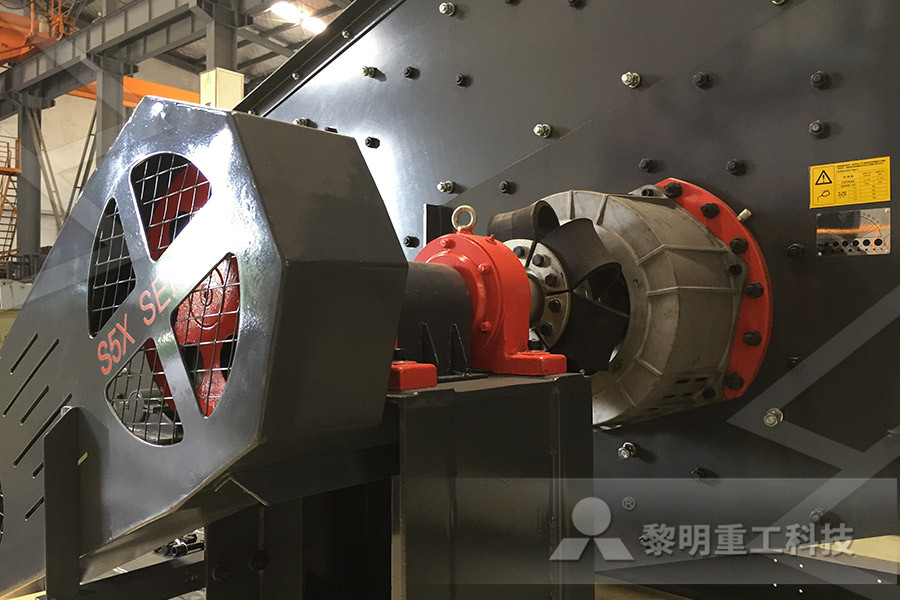

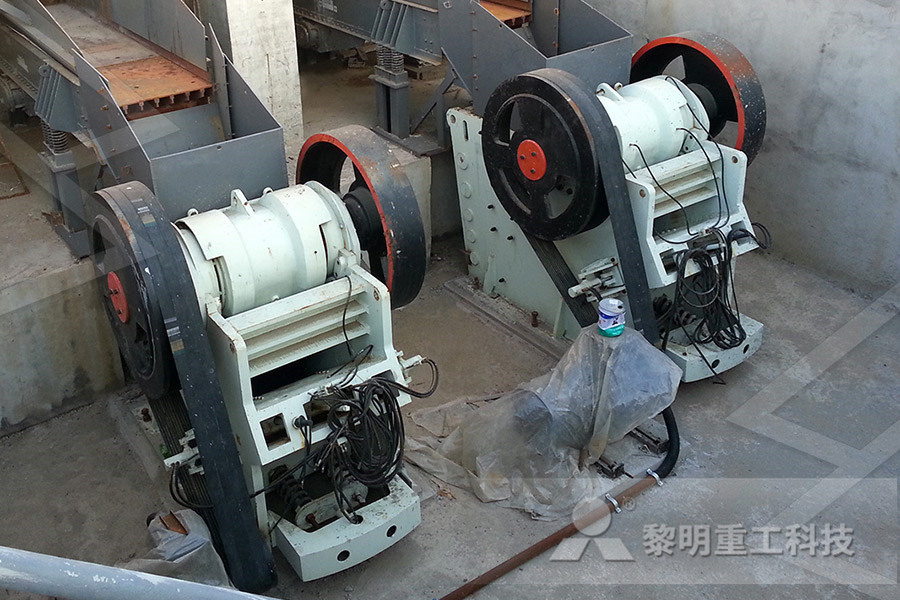

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher