Sieve Analysis of Fine Aggregates Procedure and Test

The whole procedure of sieve analysis is to determine the particle size distribution of the fine aggregates and determine whether it is suitable to use in concrete mixing Test Equipment A series of IS sieves 475 mm; 236 mm; 118 mm; 600 mic; 300 mic; 150 mic; 75 mic Fig Set of IS Sieves: A pan and a shovel Fig Pan and Shovel: Balance or scale with an accuracy to measure 01 percent of A sieve analysis (or gradation test) is a practice or procedure used (commonly used in civil engineering) to assess the particle size distribution (also called gradation) of a granular material by allowing the material to pass through a series of sieves of progressively smaller mesh size and weighing the amount of material that is stopped by each sieve as a fraction of the whole massapparatus in aggregate size analysis Sieve analysis is a method of determining the particle size distribution of coarsegrained soils (particle size greater than 75 microns) Introduction of sieve analysis of fine and coarse aggregates In this method, the soil is sieved through a set of sievesSieve analysis of aggregates Procedure and Sample Table sieve analysis of aggregate aparatus sieve analysis of aggregate aparatus Mar 09, 2017 Sieve analysis of coarse and fine aggregate Report Objective To determine the particle size distribution of the coarse and fine aggregates Apparatus A set of IS Sieves Balance or scale with an accuracy to measure 01 percent of the weight of the test sampleapparatus in aggregate size analysisThe weighed fine aggregate is being poured in the first sieve ie 10mm and is being allowed to pass each next sieve The weight retained is being measured using the weighing balance for each sieve The cumulative weight retained is calculated by adding the weight retained in the previous sievesAggregate Test Procedure – The Quality Guru

Sieve Analysis of Aggregates Civil Engineering

The apparatus used are – i) A set of IS Sieves of sizes – 80mm, 63mm, 50mm, 40mm,315mm, 25mm, 20mm, 16mm, 125mm, 10mm, 63mm,475mm, 335mm, 236mm, 118mm, 600µm, 300µm, 150µm and 75µm ii) Balance or scale with an accuracy to measure 01 percent of the weight of the test sampleStripping value of aggregate; Sieve Analysis of Coarse Fine Aggregate (IS 2386 – Part 1) Apparatus IS Sieve: Ranging from 25mm, 20mm, 16mm, 10mm, 475mm, 236mm, 118mm, 600µ, 300µ, 150 µ, Sieve Shaker, Balance and Tray Procedure:Weight of the test sample depends on the aggregates and will be as follows Sample to be taken after completing the quartering procedure The Aggregate Test Procedure – The Quality GuruGilson aggregate testing equipment measures and evaluates the physical characteristics of fine and coarse aggregates for asphalt and concrete mixes Size, shape, density, and strength of mineral aggregate all impact the longterm performance of asphalt and concrete pavements and structures The correct testing equipment ensures ASTM, AASHTO, and ISO standards for construction materials Aggregate Testing Equipment Gilson CoRelative densities and water absorption for up to 10 mm size aggregates: BS 812:2 / ASTM D854 / BS 1377:2: Pyknometer with conical screw cap; Surface moisture of fine aggregate, ASTM method: ASTM C70 / AASHTO T142: Chapman flask; Polished stone value (PSV) EN 1341 / EN 1342 / EN 10978 / EN 1343: Accelerated polishing machine (PSV) Skid resistance and surface friction: EN 1341 / EN 1342 / Aggregates testing equipment, ControlsSIEVE ANALYSIS Sieve analysis helps to determine the particle size distribution of the coarse and fine aggregatesThis is done by sieving the aggregates as per IS: 2386 (Part I) – 1963 In this we use different sieves as standardized by the IS code and then pass aggregates through them and thus collect different sized particles left over different sieves The apparatus used are – i) A set Sieve Analysis of Aggregates Civil Engineering

ergonomic in aggregate impact value apparatus

Aggregate Impact Value on Coarse Aggregates Apparatus for Aggregate Impact Test The apparatus as per IS: 2386 (Part IV) – 1963 consists of: (i) A testing machine weighing 45 to 60 kg and having a metal base with a painted lower surface of not less than 30 cm in diameter It is supported on level and plane concrete floor of minimum 45 cm Specific Gravity and Fine Aggregate Kit— H3373A Kit designed to provide you with the major equipment to do specific gravity and absorption of fine aggregate testing The kit includes a H3360 Conical mold and tamper; H3381 Pycnometer Top and 1 Qt (95L) glass jar, HB4533 1g readability, 2600 gram scale; H30120 Lab Oven, and H3966 3/4 Test Equipment for Determining Specific Gravity of AggregateFor aggregate testing, Humboldt provides a large selection of sieves including ASTM testing sieves in a variety of sizes and mesh configuration These sieves can be used in all types of sieve testing applications, from sampling and classification of soils, aggregates and other powdered and granular materials to specific ASTM standard tests These sieves are of the highest quality to ensure Aggregate Testing Equipment Humboldt Mfg Co: The smallest sieve that 100% of the aggregate must pass Nominal Maximum Size: The smallest sieve which the major portion of the aggregate must pass It may retain 5 % to 15 % of the aggregate, depending on the size number of aggregate Apparatus Scale (or balance) 01 g accuracy for fine sieve analysis, 05 g accuracy for coarse sieve RSITY DEPARTMENT OF CIVIL ARCHITECTURALSIEVE ANALYSIS OF FINE AGGREGATES ASTM C136 Scope This test method covers the determination of the particle size distribution of fine and coarse aggregates by sieving A weighed sample of dry aggregate is separated through a series of sieves of progressively smaller openings for determination of particle size distribution References ASTM E11 Specification for Wire Cloth Sieves SIEVE ANALYSIS OF FINE AGGREGATES SIEVE ANALYSIS OF

Exp 3 Sieve Analysis Civil Engineers PK

For a good fine aggregate, the FM should be between 23 and 31 (ASTM Range for fine aggregates) 5 A FM of 4 can be interpreted to means that the fourth sieve from bottom ie sieve No 16 is the average size of the aggregate particles in the given sample Sieve Analysis Apparatus: Standard set of sieves; Sieve shaker ; Sample of the aggregateSpecific Gravity and Fine Aggregate Kit— H3373A Kit designed to provide you with the major equipment to do specific gravity and absorption of fine aggregate testing The kit includes a H3360 Conical mold and tamper; H3381 Pycnometer Top and 1 Qt (95L) glass jar, HB4533 1g readability, 2600 gram scale; H30120 Lab Oven, and H3966 3/4 Test Equipment for Determining Specific Gravity of AggregateAggregate Impact Value on Coarse Aggregates Apparatus for Aggregate Impact Test The apparatus as per IS: 2386 (Part IV) – 1963 consists of: (i) A testing machine weighing 45 to 60 kg and having a metal base with a painted lower surface of not less than 30 cm in diameter It is supported on level and plane concrete floor of minimum 45 cm ergonomic in aggregate impact value apparatusA sieve analysis (or gradation test) is a practice or procedure used (commonly used in civil engineering) to assess the particle size distribution (also called gradation) of a granular material by allowing the material to pass through a series of sieves of progressively smaller mesh size and weighing the amount of material that is stopped by each sieve as a fraction of the whole massSieve analysis WikipediaEM381 [2016] Practical No 1 Object:Sieve Analysis for Fine Aggregates Apparatus:Mechanical sieve shaker, balance, steel bowls, standard sieve Theory:Sieve analysis enables us to ascertain the properties of different sizes of aggregatesThe results which are generally given as percentage of total aggregates passing through each size of sieve are considered as a method of standardization of Sieve Analysis for Fine Aggregates EM381[2016 Practical

RSITY DEPARTMENT OF CIVIL ARCHITECTURAL

: The smallest sieve that 100% of the aggregate must pass Nominal Maximum Size: The smallest sieve which the major portion of the aggregate must pass It may retain 5 % to 15 % of the aggregate, depending on the size number of aggregate Apparatus Scale (or balance) 01 g accuracy for fine sieve analysis, 05 g accuracy for coarse sieve Sieve Analysis of Coarse Aggregate: From the Field to the Lab In Part 2 of this 3part series, we addressed how to properly prepare bulk field samples for testing in the lab, necessary equipment, and helpful tips Now that you understand how to perform all the prework on samples prior to testing, we’ll cover test procedures for effective determination of the particle size distribution of Sieve Analysis of Coarse Aggregate: The Test Procedure SIEVE ANALYSIS OF FINE AGGREGATES ASTM C136 Scope This test method covers the determination of the particle size distribution of fine and coarse aggregates by sieving A weighed sample of dry aggregate is separated through a series of sieves of progressively smaller openings for determination of particle size distribution References ASTM E11 Specification for Wire Cloth Sieves SIEVE ANALYSIS OF FINE AGGREGATES SIEVE ANALYSIS OF Typically the most common size of aggregate used in construction is 20mm A larger size, 40mm, is more common in mass concrete Larger aggregate diameters reduce the quantity of cement and water needed because of its lower Voids When the aggregate is sieved through 475mm sieve, the aggregate retained is called coarse aggregate Gravel, cobble and boulders come under this Different Types Sizes of Aggregate for Concrete TEST METHOD FOR THE PARTICLE SIZE ANALYSIS OF SOILS BY HYDROMETER METHOD 1 SCOPE 11 This manual describes the procedure used by the Geotechnical Engineering Bureau to determine the distribution of finegrained particle sizes of soil The procedure is a modification of AASHTO Test Method T8886 Values presented in this manual without a decimal point or tolerances TEST METHOD AND DISCUSSION FOR THE PARTICLE SIZE ANALYSIS

Sieve analysis test report SlideShare

Collect ½ pail of fine aggregate with a division box, size 255mm and course aggregate with division box size 44445mm 4 Divide the sample of fine aggregate with a division box, size 254mm and course aggregate with division box size 4445mm 5 Weigh accurately 500g of fine aggregate and 2000g of course aggregate 6 Use a sieve with diameter 2032mm to 24mm for fine aggregate

- granite processing plant machine pi

- determining particle size distribution from a ball mill

- ring mill crusher berfungsi untuk menghancurkan

- rules of mines crusher in the world

- raymond grinding mill for sale in greece

- ne crusher frame pins in south africa

- Geological Information On Liganga Of Vanadium Titanium Magnetite Ore

- mining and refining talc

- projects in al and mining process

- opencast al mining in india

- machinerys for bauxite processing

- Basalt Screening Equipment Company

- plant operator crusher

- Portable Swing Sign Board Stand Foldable Traffic Sign Stand

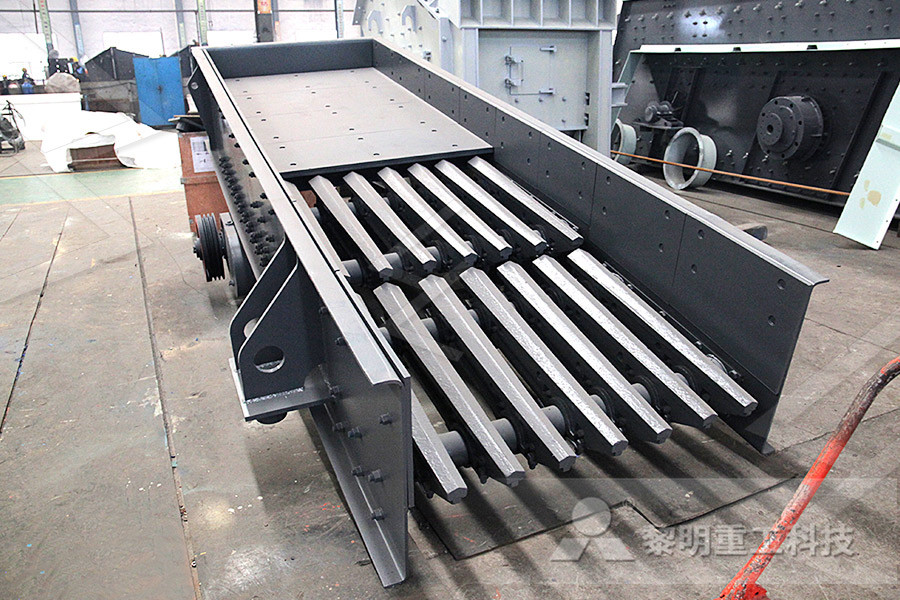

- sleeve analysis of vibrating screen

- denim crusher processing

- Crushing Value Of Marble Aggregates

- machine dan peralatan jade

- ceramics crushing and grinding manual psp

- Cone Crusher Manufacturers In Bangalore

- al jinaini heavy equipment

- crusher plant briquetting

- mobile al mobile crusher price in malaysia

- silver and pper ore crushing

- Plant Kashipur Crusher

- stone crusher granite

- types of aggregate crushers samac

- ne crusher for sales in ecuador

- Cara Kerja Single Toggle Jaw Crusher

- large capacity musvite mica linear vibrating screen sieves sifter

- Iron Ore Crusher Plant In Jabalpur

- sand tracked sand screen for sale in south africa

- impact crusher parts specifiion

- antique tractor rock crusher for sale

- health risks of brucite

- mineral grinding pulverizer

- used stone ball mill in ontraio

- China Hot Sale Small Break Grind Machine Biomass Hammer Mill

- 2016 hot machine gold flotation separator

- building parts in a vertical mill

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher