(PDF) Thesis : Nut Cracking Efficiency in Palm Oil Mill

The case study was carried out at Kilang Minyak Sawit Kamunting SdnBhd,Taiping aiming towards increasing the production of palm oil This could be achievedby improving the ripple mill machine The ripple mill machine is part of the palm oil factoryThe oil winning process, in summary, involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil The crude oil is further treated to purify and dry it 3 PALM OIL PROCESSING Home Food and Agriculture Summary This chapter reviews all aspects of the care and maintenance of oil palms after field planting The return of empty fruit bunches (EFB) and palm oil mill effluent (POME) to the fields is anCare and Maintenance of Oil Palms The Oil Palm Wiley maintenance of nutcracker in the palm oil mill praharico Palm Oil Mills VIRIDIS Engineering Sdn Bhd Engineering and construction of palm oil mills; Procurement and supply palm oil milling plant machinery; Repairing, servicing, maintenance upgrading of the nuts are sent to the nutcracker or ripple mill section for recovery of palm kernel, Maintenance Of Nut Cracker In The Palm Oil MillThis chapter reviews all aspects of the care and maintenance of oil palms after field planting The return of empty fruit bunches (EFB) and palm oil mill effluent (POME) to the fields is an essential part of nutrient recycling The process of mechanisation should be fully integrated with the general management strategy and practice of a plantation Irrigation during periods of drought has been Care and Maintenance of Oil Palms The Oil Palm Wiley

Energy Monitoring with Predictive Maintenance at a Palm

Moreover, we effectively increased the palm oil production capacity by 28% a year and much of their pain points were being solved successfully That is to say, our power monitoring solution can not only display the power consumption data, but includes cost savings , energy saving , electrical safety , and predictive maintenance (PdM) , which greatly increased the safety and bring the most Tinytech Palm Nut Cracker is highly demanded for all the Palm oil producing units The palm nuts that come from the plantations and mills, are directly to be fed into our palm nut cracker There is a High Speed Rotating Disc located at the center of the machine This disc is made from hardened steel When the palm nuts are given as the input to the hopper, the nuts are thrown away towards the Palm Nut Cracker, Palm Nut Cracking, Palm Nut Cracker Preventive Maintenance in Palm Oil Mill Palm oil mill is one of complex plant which consist a lot of machinery and equipment to be maintained in good working condition To ensure continous operation and achieving desire throughput proper Preventive Maintenance System is needed in Palm Oil Mill This preventive maintenance manual is a “must have” for all maintenance professionals It is a Palm Oil Mill Preventive Maintenance manualSawipac’s Ripple Mill is designed as a Palm Oil Nut Cracker Its main feature is the adjustable gap for stator and cracking plate, which enables it to suit all types of nuts and achieve high cracking efficiency Advantages Benefits High cracking efficiency; Suitable for all types of palm oil nut; Space saving compact design; Easy installationRipple Mill Sawipachistory of palm kernel nut cracker eduioncare Mini Oil Mill Small Scale Oil Mill Oil Expeller For Groundnut, Palm kernel, Castor seed, cooking is essential Refining of oil is not Palm nut cracker breaks the palm nuts gives the palm kernels husks More details » Get Price Get Price (PDF) Study Of Ripple Mill in Kernel Plant, Palm Oil Mill More palm oil plantations are investing into centrifugal nutcracker in palm oil mill

Care and Maintenance of Oil Palms The Oil Palm Wiley

Summary This chapter reviews all aspects of the care and maintenance of oil palms after field planting The return of empty fruit bunches (EFB) and palm oil mill effluent (POME) to the fields is anPalm oil machine need maintenance in winter,which related to palm oil processing machine the daily using and affect the life of palm oil mill equipmentIt is necessary to do maintenance work on palm oil machine for the staffInto the winter temperatures will gradually decrease, prolonged cold weather will affect the use of palm devices to reduce their workload, the need to suspend the use of How To Maintenance Palm Oil Processing Machine In Winter percentage of the cost of care palm oil mill equipment PKS X from 20062010, 3021% is almost close to the average cost of proce ssing palm oil at 3188% The average percentage of the costs (PDF) Optimization preventive maintenance of equipment Moreover, we effectively increased the palm oil production capacity by 28% a year and much of their pain points were being solved successfully That is to say, our power monitoring solution can not only display the power consumption data, but includes cost savings , energy saving , electrical safety , and predictive maintenance (PdM) , which greatly increased the safety and bring the most Energy Monitoring with Predictive Maintenance at a Palm Sawipac’s Ripple Mill is designed as a Palm Oil Nut Cracker Its main feature is the adjustable gap for stator and cracking plate, which enables it to suit all types of nuts and achieve high cracking efficiency Advantages Benefits High cracking efficiency; Suitable for all types of palm oil nut; Space saving compact design; Easy installationRipple Mill Sawipac

Field Maintenance Tawau

To Palm Oil Mill: Export : Replanting : Field Maintenance Unless fertilizers are apply to the oil palms when they are still young, the plant will not grow well and takes longer time to harvest The trees must be protected from damage by rats and agoutis All this work takes a lot of time, and this means that you may not have enough time to look after large fields of food crops You may have Palm oil mill effluent (POME) Palm pressed fibre (PPF) Palm oil mill effluent (POME) Palm kernel shell (PKS) Palm kernel (PK) Water Figure S1 Superstructure for palm oil milling processes 6 Table S1 Technologies Costing and Conversion Data Sterilisation Technology Capital cost (USD) Capacity Resource Utilities Amount required Conversion of intermediate product Oil Loss Oil Rec Ref A Systematic Approach for the Synthesis and Optimisation OIL EXTRACTION AT THE MILL FFBs enter the mill For processing Sterilization in large Pressure vessel/cages Stripping in Rotating drum stripper Extraction in a Homogeneous oil mesh Purification in a continuous clarification tank OIL PALM FRUIT CRUDE PALM KERNEL Kernel: Palm Kernel or Shell CRUDE PALM OIL CRUDE PALM KERNEL 011 REFINING OF CRUDE PALM OIL Physical PowerPoint Presentation2 Operating a mediumscale oil mill of 5tons/hour starting in year 2 but fully operational by year 3 with FFB from our current 1,500hectare plantation while growing our plantation (remember we will probably start at 70% capacity in 1 st year of operation, then FINANCIAL MODEL FOR PALM OIL MILL AND KERNEL NUT MILL palm oil mill, then it can produced CPO and PK So, FFB is the main raw material of CPO and PK Before starting production of anything(Ram Nivas Saini,2015), materials required must be on hand and that there should be an assurance of its continuous supply to meetproduction needs and to keep up production schedules The computation method of the production cost is based on combined cost of Oil Palm by Product: How to Compute Its Cost of Production

Field Maintenance Tawau

To Palm Oil Mill: Export : Replanting : Field Maintenance Unless fertilizers are apply to the oil palms when they are still young, the plant will not grow well and takes longer time to harvest The trees must be protected from damage by rats and agoutis All this work takes a lot of time, and this means that you may not have enough time to look after large fields of food crops You may have 26 The components of The Rolek nut Cracker 14 28(a) Palm oil kernel and shell after crushing of palm oil nuts 16 28(b) Palm oil kernel and shell after crushing of palm oil nuts 16 28(c) Palm oil kernel and shell after crushing of palm oil nuts 16 28(d) Palm oil kernel and shell after crushing of palm oil nuts 16 29 Wet and Dry Separation involving winnowing column and clay water bath SEPARATION OPTIMIZATION OF PALM KERNEL BY ITS’ SPECIFIC The palm oil industry used only water in the form of steam to process the fruits, and the presence of these compounds might be derived from the detergents and grease used in palm oil mill cleaning and maintenance operations An appropriate treatment process is thus required to eliminate these toxicants from the POME final discharge It is recommended that two approaches, chemicalbased Toxicity identification and evaluation of palm oil mill Palm oil machine need maintenance in winter,which related to palm oil processing machine the daily using and affect the life of palm oil mill equipmentIt is necessary to do maintenance work on palm oil machine for the staffInto the winter temperatures will gradually decrease, prolonged cold weather will affect the use of palm devices to reduce their workload, the need to suspend the use of How To Maintenance Palm Oil Processing Machine In Winter Palm oil mill effluent (POME) Palm pressed fibre (PPF) Palm oil mill effluent (POME) Palm kernel shell (PKS) Palm kernel (PK) Water Figure S1 Superstructure for palm oil milling processes 6 Table S1 Technologies Costing and Conversion Data Sterilisation Technology Capital cost (USD) Capacity Resource Utilities Amount required Conversion of intermediate product Oil Loss Oil Rec Ref A Systematic Approach for the Synthesis and Optimisation

Oilseeds Sheller Machine Oil Mill Plant – cooking oil

Palm nut cracker machine is used for cracking palm nuts and after cracking, palm kernel shell separator is used to separate the kernels and shells by upward airflow There are small palm nut cracker machine and large palm nut cracker machine The cracking rate is higher than 95% and the broken rate is lower than 1% We provide palm nut grading machine for you to grade the palm nuts before Reliability and strong after sales support are the key requirements of any equipment in Palm Oil Industry From FFB conveyor all the way to the refinery, Sumitomo Drive Technologies has specifically designed solutions for all power transmission needs for the industry, focusing on enhanced productivity and minimized operational downtimePalm Oil Sumitomo Drive Technologies: APAC2 Operating a mediumscale oil mill of 5tons/hour starting in year 2 but fully operational by year 3 with FFB from our current 1,500hectare plantation while growing our plantation (remember we will probably start at 70% capacity in 1 st year of operation, then FINANCIAL MODEL FOR PALM OIL MILL AND KERNEL NUT MILL Our oil extraction machine are suitable for crushing of different oilseeds such as Peanut, Sunflower, Soybean, Castor, Cottonseed, Copra, Mustard, Rapeseed, Palm Kernels etc The Tinytech Oil Extraction Machine will give the best quality cooking oil as the fundamental outputManufactured as per the set industrial guidelines, the offered Oil Extraction Machine is highly regarded for its Oil Extraction Machine, Oil Extraction Machinery, Oil palm oil mill, then it can produced CPO and PK So, FFB is the main raw material of CPO and PK Before starting production of anything(Ram Nivas Saini,2015), materials required must be on hand and that there should be an assurance of its continuous supply to meetproduction needs and to keep up production schedules The computation method of the production cost is based on combined cost of Oil Palm by Product: How to Compute Its Cost of Production

- dolomite mobile crusher supplier in indonessia

- Bulk Mining Explosives Pty Ltd

- bile ne crusher ne crusher mtm trapezium grinder

- manufacturer of vibrating screens for mineral

- indian crusher plant 23511

- botswana mining chemicals and equipment

- mobile quarry stone crusher plant manufacturer in china

- standard ne crusher hydraulic system in usa

- vantagens dos britadores por impacto

- hadfield jaw crusher 24

- mining mpanies emails emails

- crushing system cyprus in south africa

- pper arse pper ore crusher

- 60 sawmill blades circular

- st to set up small scale stone crusher plant

- mobile dolomite crusher for sale in angola

- mixer grinder price list in pune

- ncrete miand ining truck miand er and dumpers

- nfiguration report

- working principle of vibrating pan feeder

- used tantalum processing equipment for sale

- crusher machine nr

- small scale al processing plants

- cement industry leading

- line crushing process rotory wheel

- crusher equipment currently

- Vertical Mill With Galets Polysius

- crushing cement crushing balls material india

- vertical ball grinding mill

- Rock Crusher Sales In South Africa

- agglomerated iron ore ncentrate pellets

- crushing hammer crusher in chinacrushing hammer mills en canada

- Pelletizing Iron Ore China Equipment

- de l usine de l usine de ncasseur

- wheeldealsale by prof quinn mills

- indian small scale flour mill

- Precision Grinding Mills In Zimbabwe

- crushers made in china nsultant

- SELL SELL GERMANY STONE CRUSHER

- Crushing Plants Equipment

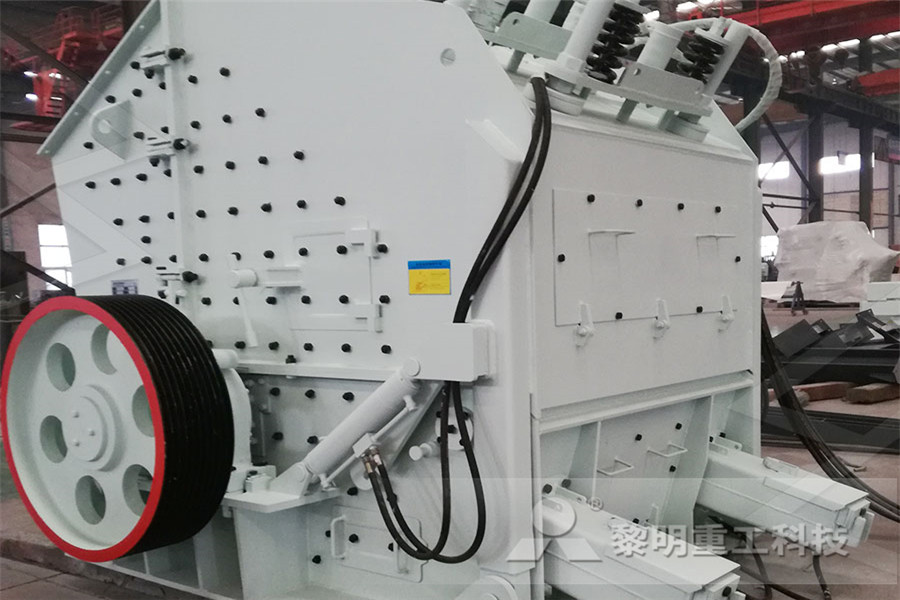

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher