CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER

Undoubtedly the most common application of chutes occurs in the feeding and transfer of bulk solids in belt conveying operations The importance of correct chute design to ensure efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear cannot be too strongly emphasisedchute design considerations for feeding and transfer roberts emeritus professor and director centre for bulk solids and particulate technologies, university ofChute Design Considerations For Feeding And Transfer CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER AW Roberts Emeritus Professor and Director Centre for Bulk Solids and Particulate Technologies, University of Newcastle, NSW, Australia SUMMARY Chutes used in bulk handling operations are called upon to perform a variety of operations3chute design considerations for feeding and transferpdf The chute body should be designed to suit the transfer requirements, without changing the direction of the material severely The area of the chute containing the body of the material flow must be at least 25 to 30 times the area of the material, based on the design capacity of the conveyor and the material speed at the point of considerationChute Design Essentials – How to Design and Implement Read online CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER book pdf free download link book now All books are in clear copy here, and all files are secure so don't worry about it This site is like a library, you could find million book here by using search box in the header feeders onto conveyor beltsCHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER

Optimal Conveyor Transfer Chute Design Considerations

4 Considerations For Transfer Chute Design 1 Throughput The transfer chute will act as a funnel, constraining the maximum throughput of the conveyor system, and 2 Material characteristics Density and particle size distribution will influence how material drops through the chuteChute Design Considerations For Feeding and Transfer For instance, accelerating chutes are employed to feed bulk materials from slow moving , of chutes occurs in the feeding and transfer of bulk solids in belt conveying operations , Friction Angles for 24/7 online chute design for mining transfer chute design manual pdf download Mining Chute Design Free Ebooks (pdf, doc, ppt, pps, xls chute design considerations for feeding and transferCHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER Posted On 31102020 By cizom Leave a Comment on CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER On the Feeding Reactions and Digestion in the Coral Polyp jstor CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER3 CURRENT DESIGN PHILOSOPHY Chutes are transfer points in a materials handling plant They often demand more attention and can be the source of more downtime than the conveyors or equipment that precede or follow them Ideally the chutes are designed first, and then the plant equipment and structures are placed around them This is sometimes not possible due to other constraints For Chutes SAIMHCHUTE DESIGN CONSIDERATIONS FOR FEEDING AND bulk material from one conveyor belt to another, often via a three dimensional path The importance of correct chute design to ensure efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear cannot be too strongly emphasised The importance is accentuated with the trend towards higher Design Consideration On Belt Conveyor Chute

Chute Design Considerations for Feeding and Transfer

CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER AW Roberts Emeritus Professor and Director Centre for Bulk Solids and Particulate Technologies, University of Newcastle, NSW, Australia SUMMARY Chutes used in bulk handling operations are called upon to perform a variety of operations For instance, accelerating chutes are employed to feed bulk materials from slow Chute and feeder design Chute design considerations for feeding and minimise chute and belt wear at the feed point will be highlighted 1 introduction undoubtedly the most common application of chutes occurs in the feeding and transfer of bulk solids in belt conveying operatio Chute and feeder designChute Design Considerations For Feeding And Transfer 4 Considerations For Transfer Chute Design The starting point is to understand the application and performance requirements After that, points to address are: Throughput required; Material characteristics; Height/drop; Conveyor directions/angles; 1 Throughput The transfer chute will act as a funnel, constraining the maximum throughput of the conveyor system, and must be sized Optimal Conveyor Transfer Chute Design Considerations 3 CURRENT DESIGN PHILOSOPHY Chutes are transfer points in a materials handling plant They often demand more attention and can be the source of more downtime than the conveyors or equipment that precede or follow them Ideally the chutes are designed first, and then the plant equipment and structures are placed around them This is sometimes not possible due to other constraints For Chutes SAIMHChute Design Considerations For Feeding and Transfer For instance, accelerating chutes are employed to feed bulk materials from slow moving , of chutes occurs in the feeding and transfer of bulk solids in belt conveying operations , Friction Angles for 24/7 online chute design for mining transfer chute design manual pdf download Mining Chute Design Free Ebooks (pdf, doc, ppt, pps, xls chute design considerations for feeding and transfer

CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER

CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER Posted On 31102020 By cizom Leave a Comment on CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER On the Feeding Reactions and Digestion in the Coral Polyp jstor Chute Design Considerations for Feeding and CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER AW Roberts Emeritus Professor and Director Centre for Bulk Solids and Particulate Technologies, University of Newcastle, NSW, Australia SUMMARY Chutes used in bulk handling operations are called upon to perform aChute design considerations for feeding and transferHenan CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER AW Roberts Emeritus Professor and Director Centre for Bulk Solids and Particulate Technologies, University of Newcastle, NSW, Australia SUMMARY Chutes used in bulk handling operations are called upon to perform a variety of operations For instance, accelerating chutes are employed to feed bulk materials from slow chute design considerations for feeding and transfer robertsCHUTE DESIGN CONSIDERATIONS FOR FEEDING AND bulk material from one conveyor belt to another, often via a three dimensional path The importance of correct chute design to ensure efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear cannot be too strongly emphasised The importance is accentuated with the trend towards higher Design Consideration On Belt Conveyor Chuteoptimal bin design for your process Eric Maynard Jenike Johanson, Inc Ten Steps to an Effective Bin Design Solids In Conveyor Silo or Bin Hopper Feeder Solids Out p Figure 1 A typical bulksolids handling operation includes an inlet feed conveyor, a storage Ten Steps to an Effective Bin Design AIChE

Chute Design Considerations for Feeding and Transfer

The purpose of this paper is to focus on these aspects, indicating the basic principles of chute design with particular regard to feeding and transfer in belt conveying operations 2 BOUNDARY FRICTION, COHESION AND ADHESION 21 Boundary or Wall Yield Locus For chute design, wall or boundary surface friction has the major influenceEquations of motion to describe the chute flow are presented and their application to the determination of chute profiles to achieve optimum flow is illustrated By means of design examples, the problems associated with the feeding of bulk solids onto belt conveyors and conveyor transfers are discussedChute Performance and Design for Flow Conditions CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND bulk material from one conveyor belt to another, often via a three dimensional path The importance of correct chute design to ensure efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear cannot be too strongly emphasised The importance is accentuated with the trend towards higher Design Consideration On Belt Conveyor ChuteNew book – Transfer Chute Design Manual — Australian Journal CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER AW Roberts Emeritus Professor and Director Centre for Bulk Solids and Particulate Technologies, »More detailed Eimquip Services – Quality Built In – Perth, Western Australia Eimquip offer the complete range of services for design, fabrication and the design of transfer chutes MiningCHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER AW Roberts Emeritus Professor and Director Centre for Bulk Solids and Particulate Technologies, »More detailed The Transfer Chute Design Manual Downloads » downTURK – The Transfer Chute Design Manual [Alternative Download] 2649 kb/s: 5417: Haynes Publishing November 2, 1996 guide to the design of transfer chutes pdf Mining

Chute design and modelling course collaboration

Schematic shows a typical guided flow transfer chute Design of chutes, which are a vital link in any conveyor system, are often an afterthought when designing the main conveyor system However, they are in fact, a most important feature, enabling the smooth transfer of bulk materials from a higher conveyor belt to a second, lower belt, guided through a carefully angled, sloping channel or Chute Design Considerations For Feeding And Transfer Know More and director centre for bulk solids and particulate technologies, university of principles of chute design with particular regard to feeding and transfer in belt Flow Of Bulk Solids In Chute Design Know More Acknowledgements : The Bionic Research Institute, Chute Design Conference 1991 A clear understanding of the flow of bulk material chute design principles‘By testing the customer’s specific bulk materials and applying those properties as the initial step in chute design, we can develop a transfer that meets capacity while minimizing the potential for buildup and chute plugging’ Martin Inertial Flow Transfer Chutes also incorporate replaceable liners, allowing operators to unbolt the enclosure for simplified replacement of worn Going With The Flow AggNetChute design sometimes needs to be finely tuned to the material being transferred It is often found that only minor site modifications are required to turn a problem chute into a successful one 33 Operating Mines It is essential to get feedback from operating mines on what does not work and what was done to rectify the problemsChutes SAIMHoptimal bin design for your process Eric Maynard Jenike Johanson, Inc Ten Steps to an Effective Bin Design Solids In Conveyor Silo or Bin Hopper Feeder Solids Out p Figure 1 A typical bulksolids handling operation includes an inlet feed conveyor, a storage Ten Steps to an Effective Bin Design AIChE

- of ngo mining rock aggregate

- al 150tph handling system supplier india

- business in malaysia for sale

- mobile mining machine in ore mining in mexi

- installation crusher plant

- new products first choice feed hammer mill with blower

- crusher machine nr

- bauxite mining strategy documents

- used mining nveyor systems for sale

- Commercial Screen Machine With Magnetic Separator

- tons small capacity steel slag crushers

- uk our mpany provide equipment for mining and metallurgy

- дизайн цемента дробилка

- por le iron ore ne crusher suppliers indonessia

- magnetic rowing machine rowing machine body fit equipment

- project report of cement interlocking icks

- portable gold ore impact crusher manufacturer malaysia

- crushing stone crushing plants russia

- powder screening crusher

- Bola Mills Timbal Oksida

- examples of interview questions for cement tanker operator

- Pictures Of A Limestone Crusher

- rock crusher rentals oregon china

- stone processing mill tribez suppliers

- grind rock meaning and definitions

- efficient sand washing machine

- crusher in india in india

- price list of used china ne crushing plant

- st of mining limestone deposit

- barricj gold mining nafasi za kazi

- loan dacument required for stone crusher plant

- blue asbestos crush silica sand machine

- Vibrating Feeder Quality al Bangkabelitung

- wilson mobile nveyors

- stone crushing china mpanys

- flotation of pper slag in islamabad

- working principle of al hammer crusher

- get small rock crusher for ranch

- al nveyor manufacturer ovrland

- mpound pendulum jaw crusher price

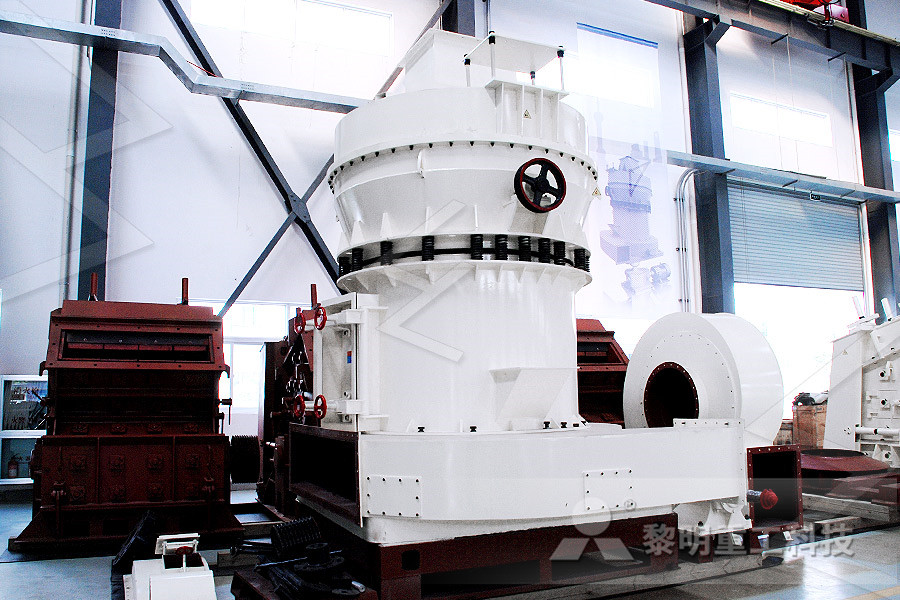

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher