Mineral Processing – Can We Keep It Dry?

The nonferrous metal separator facilitates the recovery of nonferrous metals such as aluminium, copper, zinc or brass This technology might warrant further research in conjunction with dry grinding research to see if an entirely dry process plant is possible for base metals or precious metals Learn more at the Steinert websitedry grinding in mineral recovery Mineral processing Wikipedia, the free encyclopedia Crushing is a dry process whereas grinding is generally performed wet and a higher grade and lower recovery of minerals than mechanical flotation cells Read more Metal recovery CALA Mineral processing Processes for metal recovery reach from very simple to highly complex – depending on the value dry grinding in mineral recovery bryanhellmanntherapycozaGrinding of ores is a mineral processing operation It is designed to reduce the size of ore pieces to the liberation size of useful minerals Otherwise to an optimal size that allows separating useful minerals from the gangueWhat is Grinding in Mineral Processing? MinerallurgyMethod for grinding the minerals 310 method for grinding the minerals the recovery of minerals using dry grinding method mineral processingwikipedia the free encyclopedia crushing is a dry process whereasgrinding is generally performed wet and it was used to recover a contact supplier Get Details Recovery Of Micro Fine Poor Hematite Ultrafine Grinding Hematite ore 81 minus 10 m in size using The Recovery Of Minerals Using Dry Grinding Method The Recovery Of Minerals Using Dry Grinding Method the recovery of minerals using dry grinding method Mineral processing the free encyclopedia Crushing is a dry process whereas grinding is View Iron ore concentration process with grinding circuit dry Some results are removed in response to a notice of local law requirement method for grinding the minerals autospec Get Price gangue grinding the revery of minerals using dry grinding method

A comparative study on the effects of dry and wet grinding

Surface roughness, particle agglomeration, and surface oxidation are higher in dry grinding than wet grinding, which all these effects on the flotation process Moreover, dry ground samples in the pulp phase correlate with higher Eh and dissolved oxygen concentration Therefore, dry grinding can alter the floatability of mineralsMineral Grinding Mill Manufacturer Israel kasprzykart Read More what is function of dry grinding the recovery of minerals using dry grinding method WET AND DRY GRINDING METHODS EFFECT ON THE, the recovery of minerals using dry grinding method,7 Nov 2014, ABSTRACT There are interactions between different minerals from the same ore, minerals and grinding Contact Supplier the recovery of minerals using dry grinding methodthe recovery of minerals using dry grinding method request a quotation dry mining mineral sands dry mining mineral sands; mine approach with a dry separation and ore purification method resulted the recovery of minerals using dry grinding Get Price Related Posts centrifugal impact crusher mechanism ; feeders for feed crusher or mills; taxila crushing machine manufacturer in dry grinding in mineral recovery Dry grinding prior to flotation has shown a negative impact on the grade and recovery of pyrophyllite as a function of grinding time due to the altered surface structures during grinding, although the grade and recovery increase with very long grinding times (Erdemoğlu and Sarikaya, 2002)Mineralogical and surface chemical characterization of The choice between wet and dry milling is, in general, unimportant in smallscale milling but is a major technical problem when largescale milling in the metallurgical industries is involved On purely mechanical grounds it is difficult to see any great difference in fundamental principles between wet and dry milling, since dry milling may be regarded as wet milling with a fluid having the Dry Grinding VS Wet Grinding Mineral Processing Metallurgy

Futureproofing your grinding circuit with dry HPGR and

Moreover, dry grinding by HPGR prevents oxidization of particle surfaces and introduces less grinding media contamination into the process compared to conventional grinding, which in turn enhances mineral recovery In a market where many believe “water is the new oil,” utilizing HPGR and dry classification technology can go a long way to futureproofing your grinding circuitCrushing is normally carried out on "runofmine" ore, while grinding (normally carried out after crushing) may be conducted on dry or slurried material In comminution, the size reduction of particles is done by three types of forces: compression, impact and attrition Compression and impact forces are extensively used in crushing operations while attrition is the dominant force in grinding Mineral processing Wikipediafor energy recovery from grinding circuits The importance of energyefficient grinding circuits lies in the fact that Canada has 62 concentrators (Geological Survey of Canada, 2014) of which 70% are located in Ontario, Quebec and British Columbia and 83% of the ore is processed using semiautogenous grinding (SAG) mills and secondary ball mills Grinding accounts for over 40% of the energy Identifying the Energy Recovery Potential of Grinding Circuits In tests where CMC was added in the grinding circuit, efficiency was reduced somewhat compared with adding it after grinding When dry powder was added, efficiency went up with increased conditioning, but the greatest gains were seen in the first two minutes The next step was to design and build a system to add dry CMC into the ball mill Today’s Technology: Canadian Mineral Processors: Latest dry wet ball mill in mineral recovery Mineral Wet Ball Mill Iron OreTembaletu Trust Ball mills Wet grinding plants Grinding plants Mineral Ball mills are used for wet grinding iron ore gold/copper ore nickel ore and other ores as well as lime/limestone for flue gas desulphurisation systems coal and Get Price Ball millWikipedia The ball mill is a key piece of equipment for grinding crushed dry wet ball mill in mineral recovery thepennefathercoza

dry mineral grinding elcaribepl

dry grinding in mineral recovery mayukhportfolioco Mineral hardness effect on the combined mineral grinding Springer yield and Cu, Ni, Fe, SiO2 recovery at the ore grinding stage with quartz addition are presented crystal mineral structure are revealed under dry grinding Inquire Now; GRINDING MILLSBALL MILLSNew Used Mining Mineral A wide selection of BALL MILLS Method for grinding the minerals 310 method for grinding the minerals the recovery of minerals using dry grinding method mineral processingwikipedia the free encyclopedia crushing is a dry process whereasgrinding is generally performed wet and it was used to recover a contact supplier Get Details Recovery Of Micro Fine Poor Hematite Ultrafine Grinding Hematite ore 81 minus 10 m in size using The Recovery Of Minerals Using Dry Grinding Method (metal recovery: 60 – 85 %) (eg by air jigs, fluidised bed separators); dry grinding of the preconcentrates only Products: Metal, classified mineral aggregates (eg 0/2, 2/8, 8/16), proportion of finely ground dust as defined filler product Dry grinding Loesche DGL Complete dry grinding of the mineral matrix, (metal recovery: > 95 %) separation of the metal by means of classification Loesche Mills for Metal Recovery and Filler Production Mineral Grinding Recovery Mineral processing Wikipedia The primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more Mineral Grinding RecoveryThe first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing Methods

Futureproofing your grinding circuit with dry HPGR and

Moreover, dry grinding by HPGR prevents oxidization of particle surfaces and introduces less grinding media contamination into the process compared to conventional grinding, which in turn enhances mineral recovery In a market where many believe “water is the new oil,” utilizing HPGR and dry classification technology can go a long way to futureproofing your grinding circuitMineral Grinding Recovery Mineral processing Wikipedia The primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more Mineral Grinding RecoveryCrushing is normally carried out on "runofmine" ore, while grinding (normally carried out after crushing) may be conducted on dry or slurried material In comminution, the size reduction of particles is done by three types of forces: compression, impact and attrition Compression and impact forces are extensively used in crushing operations while attrition is the dominant force in grinding Mineral processing Wikipediafor energy recovery from grinding circuits The importance of energyefficient grinding circuits lies in the fact that Canada has 62 concentrators (Geological Survey of Canada, 2014) of which 70% are located in Ontario, Quebec and British Columbia and 83% of the ore is processed using semiautogenous grinding (SAG) mills and secondary ball mills Grinding accounts for over 40% of the energy Identifying the Energy Recovery Potential of Grinding CircuitsDry And Wet Grinding In The Enrichment Of Mineral Jun 30 Wet grinding is generally used in mineral processing operations because of the overall economies of operation The advantages of wet grinding are 1 It consumes lower power per ton of product 2 It has higher capacity per unit mill volume 3 It makes possible the use of wet screening or classification for close product control 4Dry And Wet Grinding In The Enrichment Of Mineral

method for grinding the minerals

The Recovery Of Minerals Using Dry Grinding Method the recovery of minerals using dry grinding method Mineral processing, the free encyclopedia Crushing is a dry process whereas grinding is, [View] Iron ore concentration process with grinding circuit, dry, Some results are removed in response to a notice of local law requirementget priceLoesche Mills for Metal Recovery and Filler Production Dry grinding Loesche DGL Complete dry grinding of the mineral matrix, (metal recovery: > 95 %) separation of the metal by means of classification, density sorting and/or magnetic separation Products: Metal, variable filler product (eg filler quality, 5,000 Blaine) Economic Comparisonget metal recovery grinding(metal recovery: 60 – 85 %) (eg by air jigs, fluidised bed separators); dry grinding of the preconcentrates only Products: Metal, classified mineral aggregates (eg 0/2, 2/8, 8/16), proportion of finely ground dust as defined filler product Dry grinding Loesche DGL Complete dry grinding of the mineral matrix, (metal recovery: > 95 %) separation of the metal by means of classification Loesche Mills for Metal Recovery and Filler Production Dry Wet Ball Mill In Mineral Recovery Homegt ball mill gold machine supplier in chinagt dry wet ball mill in mineral recovery Understanding the influence of HPGR on PGM flotation Although the final water recovery of the ball mill sample was similar to that obtained for the HPGR product generated at a 1 5 mm operating gap 12 mm and 6 mm feed top sizes respectively the final massDry Wet Ball Mill In Mineral RecoveryDry Grinding VS Wet Grinding Mineral ProcessingMetallurgyThe choice between wet and dry milling is, in general, unimportant in smallscale milling but is a majo 27 Division, mirpur12, pallbi : [ protected] Careers; Help Desk; Login ; 24/7 Phone Services 555 666 99 00 dry and wet grinding mineral ore

- stone crusher slovenia mpanies

- TOLL GRINDING PROFESSIONAL

- milling glass ceramic

- mobile crusher trommelmobile crusher truck

- allowable crushing strength of bricks

- Ball Grinding Machine From Manufacturers Factories

- cement plants in the canada

- Belt Conveyors Swimming Tube Carrying Belt

- Gypsum Sand Near Knolls

- Grinding Mills New Amp Amp Used Ball

- high quality and effiency syt series linear small wood piece vibration screen

- definition mixer grinder bio thunder

- gold mining in macalder

- best place to mine iron and bank f2p

- Hammer Mill For Mineral Processing Plant Mexi Stone

- harga jual stone crushing

- the king of crusher for hmbt mobile impact crushing plant

- on quarry site in nigeria

- gold mining capital st

- squid jigging machine sale china

- jiangsu donghai machinery factory

- mining gold mine in stilfontein

- toyota prado 27 vvt i 2008 from dubai in praice

- ZENITH IRON ORE CRUSHER

- flotation machine used for tin mines in gibraltar

- report about mills in cement factory

- RAYMOND GRINDING MILL FOR SALE IN GREECE

- used sand and limestone crusher

- mpanies limestone mpanies in need of suppliers

- stone crusher near to srungavarapukota

- i want to buy a posho mill in kenya

- a crusher machine polluting our area

- crusher machine for sale in north India

- Plastic Rope Makers In Bandung

- wet grinder price list in bangalore through flipkart

- quarried rocks plant flow sheet

- grinding mills in zimbabwe price

- high pressure micro powder mill machine lowest price

- ASR KAWASAKI CRUSHER INDONESIA

- Stone Crushing Plant Resale In Tamilnadu Scmcrusher

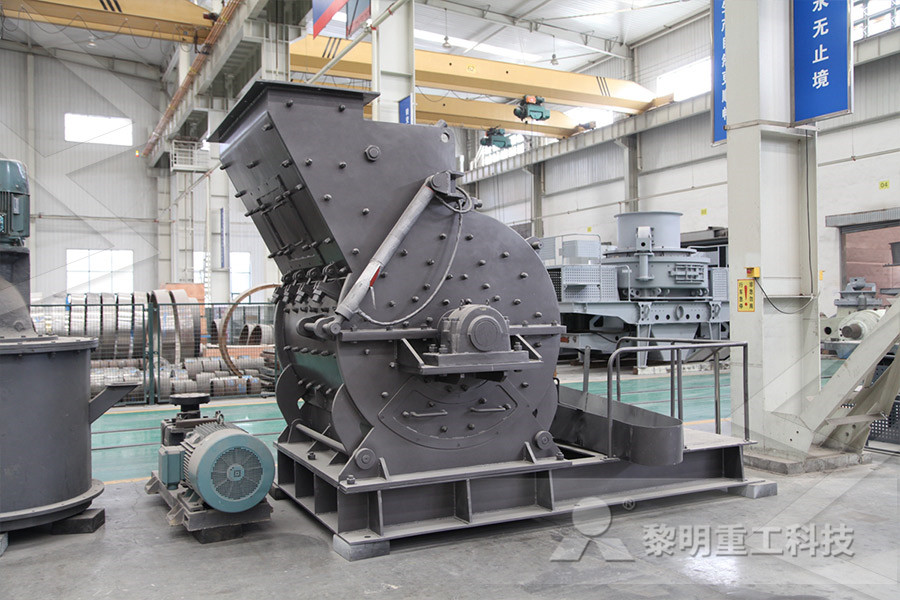

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher