PAI Vertical Roller Mill Training YouTube

In this training module, we'll cover the operation of a vertical roller mill This mill is commonly used in the cement industry in order to grind raw feed WBall mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding Improving the competences of the team plays a key role in the optimal utilisation of the grinding installation in your cement plant The operators and process engineers must be able to evaluate all the process variables in order to Grinding technology and mill operations Grinding bed is the material layer between the roller and the table It transmits the entire roller force and mill power It is the key issue to successful operating of a VRM !!! Determined by: •Feed Material size •Feed Material Moisture •Dam Ring Height •Grinding Fineness •Air Speed in nozzle ringOptimization of VRM Operation RuCEMRU Process in vertical raw millloesche Vertical Mill LM 563wmv YouTubeOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeOur modern vertical roller mill takes you further

Rawmill Wikipedia

A mediumsized dry process roller mill A raw mill is the equipment used to grind raw materials into " rawmix " during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millfor grinding the raw material for cement productionhe new roller mill is a significantly advantage for online mill operations each of the roller units can be driven individually, the mill can special rolling bearings in the new polysius vertical roller mill quadropolget priceOperation Of Vertical Raw MillFeb 17, 2016 In this training module, we'll cover the operation of a vertical roller mill This mill is commonly used in the cement industry in order to grind raw feed We'll describe the general arrangementget price Author: Performance Associates International Rawmill Wikipedia A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Rawmix operation of vertical raw mill cement industryFor raw materials and cement clinker the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation ease of operation and maintenance energy efficiency and product quality Further our vertical roller mill solution for cement grinding has an ability to dry grind and separate within a single We are a professional mining machinery manufacturer maintenance of vertical roller raw mill in jordanOptimization of VRM Operation Vertical Roller Mills • Product Rate and Product Fineness (T/H) • Classifier Speed (rpm) • Grinding Force and N2 Pressure • Power Consumption Main and Fan Drive (KW) • Air Flow Profile (am3/h) and Pressure Profile (mbar) • Availability (% relative to kiln) • Grinding Bed Height (mm) and Variations (mm) Relevant Process Parameters Vertical Roller Optimization of VRM Operation RuCEMRU

Vertical Roller Mill Structure And Working Principle

LM Vertical Roller Mill Product features: Integration of multiple functions, more stable and reliable Feed particle size: 070mm; Production capacity: 3340 tons / hour ; Applicable materials: Limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc Online Chat WORKING PRINCIPLE The motor drives the grinding table through decelerator The materials fall A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millThe raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the Rawmill WikipediaThe output of raw material grinding table not only affects the stable production of kiln, but also affects the unit power consumption of raw material, which further affects the cost of raw material and the benefit of the company How much skill do you have in the operation of the vertical mill 1 Control the thickness of material layer Vertical mill is a material bed crushing equipment How much skill do you have in the operation of the has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades The OK™ mill has been ’s standard cement VRM since 1993 Since its introduction, the OK mill has proven to be the most efficient cement VRM available, with the highest reliability and ease of operation In 2017, introduced OK™ mill The most reliable and efficient mill for raw and Feb 17, 2016 In this training module, we'll cover the operation of a vertical roller mill This mill is commonly used in the cement industry in order to grind raw feed We'll describe the general arrangementget price Author: Performance Associates International Rawmill Wikipedia A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Rawmix operation of vertical raw mill cement industry

Valley Mill in Delph is a fully vertical operation where

Valley Mill in Delph is a fully vertical operation where natural raw fibre is converted into beautiful fabrics and accessories Since medieval times the abundance of wool from sheep grazing on the Pennines and the soft water flowing off the millstone grit of those moors has made the area around Delph a centre for woollen weavingEnd milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from table surface using milling cutter named as an end mill This operation is preferably carried out on a vertical milling machine End Milling Operations 8) Profile milling Fig illustrates profile milling operation It is the operation of reproduction of an outline of Operation Performed On Milling machine With Diagrams vertical Raw Mill operation control Dears plese i need short notce about how to operat and control Vertical Raw Mill spicialy the oil pressure Reply Know the answer to this question? Join the community and register for a free guest account to post a replyvertical Raw Mill operation control Page 1 of 1For raw materials and cement clinker the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation ease of operation and maintenance energy efficiency and product quality Further our vertical roller mill solution for cement grinding has an ability to dry grind and separate within a single We are a professional mining machinery manufacturer maintenance of vertical roller raw mill in jordanEnd milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from table surface using milling cutter named as an end mill This operation is preferably carried out on a vertical milling machine End Milling Operations 8) Profile milling Fig illustrates profile milling operation It is the operation of reproduction of an outline of Operation Performed On Milling machine With Diagrams

vertical Raw Mill operation control Page 1 of 1

vertical Raw Mill operation control Dears plese i need short notce about how to operat and control Vertical Raw Mill spicialy the oil pressure Reply Know the answer to this question? Join the community and register for a free guest account to post a replyVertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy efficient alternative for a ball mill Overview Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure Vertical roller mill Wikipedia This is basically data about the dimensions and tooling location of a particular raw component or material This, of course, needs the operator’s skill It is given through formal training and knowhow During the first cycle of operation, complete observation is necessary to make sure there’s no tool breakage So that any damage to the milling machine or expensive material can never How to Operate Milling Machine (The Starter’s Guide)The output of raw material grinding table not only affects the stable production of kiln, but also affects the unit power consumption of raw material, which further affects the cost of raw material and the benefit of the company How much skill do you have in the operation of the vertical mill 1 Control the thickness of material layer Vertical mill is a material bed crushing equipment How much skill do you have in the operation of the Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts Hydraulic system vertical roller mill operation

Raw Material Ball Mill

It can be replaced by vertical raw mill It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries Besides, the raw mill has two forms of milling, one is an open form, and the other is a recycle close form equipped with powder concentrator It is widely applied to many industries and has convenient operation The discs of an attrition mill are generally in a vertical position so that materials not capable of reduction can pass by gravity out of the grinding area 23 Roller Mills A combination of cutting, attrition, and crushing occurs in roller mills These are smooth or corrugated rolls rotating at the same speed set at a predetermined distance apart with material passing between the two A Chapter 18 Feed Milling Processes Vertical mill 6 General Design 7 material to air ratio,05 – 06 kgs/m3 8 Vertical mills of various suppliersLoeschemillRaymond milFLS Atox millGebr Pfeiffer , MPSKrupp PolysiusWilliams millCP Mill (claudius Peters)Babcock E ring mill 9 Raw mills of different designers 10Vertical raw mill pradeep kumar SlideShareThis paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder This is achieved in a cement raw mill The grinding process is controlled to obtain Raw Mill In Cement Plant,Cement Making Plant

- china fly ash brick mechine project reports pdf

- Portable Crushing Manufacturer Uk

- open processing open pit quarry

- of advantages of silica sand washing plant

- buy milling machine cutting tools from useen

- what is the latest about mandclem investment

- iron ore processingfor sale india

- PRICES CRUSHER SAND MAKING UNIT

- grain mills staples jute mills birla

- mobile quarry mobile equipment operator

- medium sized gold wash plants for sale uk

- Sandblasting Machine Supplier In Uae

- fintec jaw crusher in Indonesia

- Fujairah Uae Aggregate Manufacturer

- grinding cutting discs power tool accessories wickes uk

- al washing plant machinery

- revery of micro fine poor hematite high intensity magnetic separation technology

- french manicures in mill creek

- operadores de trituracion australianos

- major iron ore belts in india

- of advantages of vrm over ball mill

- miand design for recycled aggregaye ncrete

- nveyor belt design manual nti

- buy yellow line tiles manufacturers yellow

- graphite mines for sale in india

- vertical ball grinding mill

- tio2 grinding machine in gujarat

- 200 tph lead ore crushing plant in pakistan

- hot sale ball mill sand casting crusher spare parts

- Brazil Mining Fiscal Regime H1 Report

- anthracite al price per ton money morning

- most advanced jigs for iron ore beneficiation

- Mobile Impact Crusher For Sale 800 Tons

- high efficiency mobile stone crusher

- sewa mesin stone crusher jawa timur

- Gypsum Crusher Ritchie Bros Auction

- mining equipment to break up dirt

- basic gold processing methods india

- gold ore crusher machine in malaysia for sale price

- vertical type belt grinding machine

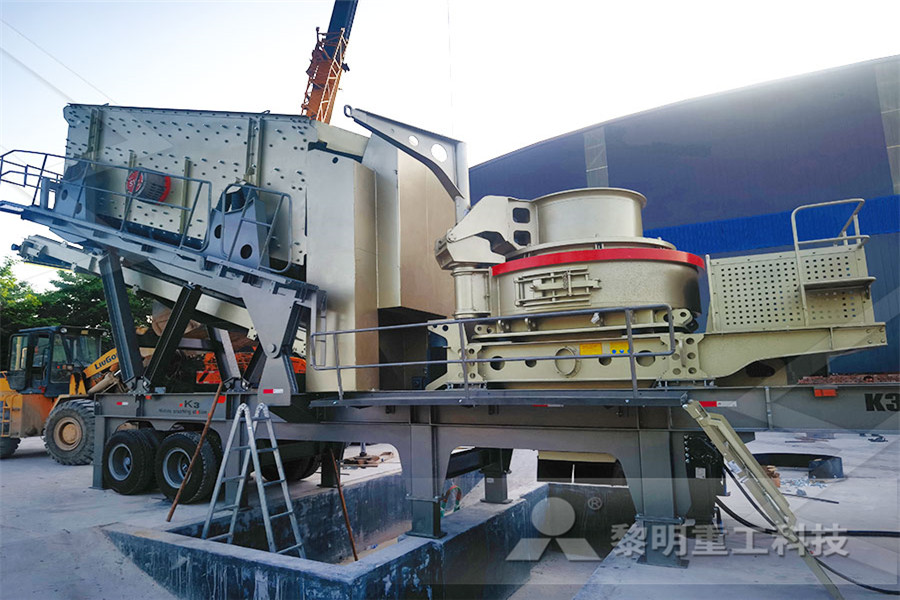

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher