Magnetic Conveyors,Industrial Magnetic Belt Conveyors

MADE IN USA Puritan Magnetics offers quality, durable material handling belt and belt free magnetic conveyors to suit many industries Permanent and Electromagnetic rails are used below the belt to attract ferrous metal to the surface A variety of designs are available (see below)Magnetic belt conveyors are created by placing permanent ceramic magnets in the bed of a standard conveyor These magnets can hold ferrous, or ironcontaining, parts and run as any industrial conveyor should run The magnets are placed with precision, providing the perfect magnetic holding power for these partsMagnetic Conveyors Conveying and Manufacturing Dorner A magnetic conveyor utilizes a permanent magnetic core to retain ferrous materials to a conveying belt Ferrous material/parts are introduced at a specified load point; a magnetic field emanating from below the conveyor belt attracts and retains the ferrous material to the belt surfaceMagnetic Conveyors – Innovative Magnetic TechnologiesIPES International, Inc can simplify the process by providing companies with crossbelt electromagnets and magnetic conveyor belts that are designed to help them screen, separate, and sort ferrous metals You can upgrade your sorting, recycling, crushing, and disposing processes by utilizing suspended separation magnetics in your facilitySuspended Electromagnetic Magnets Magnetic Conveyor GTSXG series Drum Magnet is a new type of highefficiency and energysaving magnetic separator using on conveyors of different specifications It is mainly used for iron separation of scrap metal or steel slag in iron factory, foundry workshop and metallurgical plantDrum Magnet Conveyor Belt Magnetic Separation GTEK

Magnetic Conveyors – Innovative Magnetic Technologies

A magnetic conveyor utilizes a permanent magnetic core to retain ferrous materials to a conveying belt Ferrous material/parts are introduced at a specified load point; a magnetic field emanating from below the conveyor belt attracts and retains the ferrous material to the belt surface As the belt is moving, the ferrous material moves along with the belt to the desired discharge location Metal Stamping America’s most complete line of permanent magnetic conveyors and conveyor components for the Metal Stamping Industry Printing Precisionbuilt Bunting magnetic cylinders and flat bases make your existing press a better, and productive All Industries; Request a Quote Get in touch with us at our tollfree number 18008352526 or request a quote here: Talk to an expert Conveyor Belt Magnets Bunting MagneticsDrum Magnet is generally placed at the end of the conveyor belt for the separation of scrap steel in most recycling industries, GTSXG series Drum Magnet is a new type of highefficiency and energysaving magnetic separator using on conveyors of different specifications It is mainly used for iron separation of scrap metal or steel slag in iron factory, foundry workshop and metallurgical Drum Magnet Conveyor Belt Magnetic Separation GTEKMagnetic belt conveyors hold materials firmly and keep them moving, virtually eliminating the problem of jamming and reducing the need formanual handling No side rails or side wipers are required on Eriez conveyors because the magnetic field holds ferrous material on the center of the belt Sharp scrap or small pieces are kept from beneath the belt where they could cause belt damage and Eriez Magnetic Belt ConveyorsOur SMS magnets (Suspended Magnetic Separator) are cross belt separator permanent magnets designed for separation of ferrous metal from a variety of overthebelt conveyor applications Proven in industries such as Mining, Aggregate, Recycling, Tire Shredding, Foundry, Wood Chip, Pulp Paper, Power Generation, Construction and DemolitionIndustrial Magnetics, Inc Conveyor Line

Overhead Magnetic Separators Conveyor Magnets

Shields magnetic separators and belt magnets serve as an insurance policy in industrial applications ranging from food and aggregate processing to coal mining and plastics production and recycling Our separation equipment removes damaging ferrous metal from raw and finished materials throughout all stages of production including conveyor belts, grain hoppers and flow systems Adding overhead Crossbelt or belt magnets, also known as overhead magnetic separators, offer a practical and efficient method for separating ferrous metal from fastmoving materials on conveyors Our belt magnets utilize TriPolar Magnetic Circuitry, exclusive to the industry! Crossbelt magnets reclaim a higher percentage of valuable steel; Belt Magnets Easily interchangeable from one machine to anotherCrossBelt Magnets Shields MagneticsMagnetic Conveyors AG08B Key Markets Stamping, Fabrication, Appliance, Blanking, Steel Service Centers Related Products Sheet Fanners, Transporters®, Electromagnets INTRODUCTION: IMI's Magnetic Transfer Conveyors are ideal for automating part handling in various industries including: Automotive, Appliance and Offi ce Furniture Magnetic Transfer Conveyors contain permanent, Magnetic Conveyors AG08B Industrial Magnetics, IncOur Magnetic Head Pulleys is specially design for conveyor systems to continuously remove and discharge tramp metal from the product flow for purification and materials separation These magnetic head pulleys is more preferable for superior removal of ferrous contamination such as spikes, nuts, nails, cans any many other unnecessary materialsMagnetic Head Pulleys for Conveyor Systems Manufacturer Magnetic belt conveyors are built using permanent ceramic magnets in the aluminium profile bed of a standard conveyor belt system This allows the magnets to attract ferrous parts through the belt and run as any normal industrial conveyor The magnetic forces are calculated and the magnets are placed with precision, providing a perfect magnetic holding power The conveyor and magnets are Magnetic belt conveyor systems for ferrous materials

Eriez Magnetic Belt Conveyors

Magnetic belt conveyors hold materials firmly and keep them moving, virtually eliminating the problem of jamming and reducing the need formanual handling No side rails or side wipers are required on Eriez conveyors because the magnetic field holds ferrous material on the center of the beltThe magnetic belt conveyor is one of the surest way how to control positioning of ferrous parts (such as metal scrap from machining, pressing, grinding etc) during the transport for further processing Advantages of magnetic belt conveyorsMagnetic belt conveyors MD SOLLAU sroCrossbelt or belt magnets, also known as overhead magnetic separators, offer a practical and efficient method for separating ferrous metal from fastmoving materials on conveyors Our belt magnets utilize TriPolar Magnetic Circuitry, exclusive to the industry Pricing, Specs, More Info Pulley Magnets Protect Against Tramp Iron ContaminationOverhead Magnetic Separators Conveyor MagnetsMagnetic belt conveyors are important magnetic product that provides holding action for vertical, inclined or horizontal material handling for conveying, automation and part handling applications Magnetic conveyors are created by placing permanent ceramic rare earth magnets in the bed of a Magnetic Belt Conveyors – Material Handling MagnetCrossbelt Crossbelt or belt magnets, also known as overhead magnetic separators, offer a practical and efficient method for separating ferrous metal from fastmoving materials on conveyors Our belt magnets utilize TriPolar Magnetic Circuitry, exclusive to the industry! Crossbelt magnets reclaim a higher percentage of valuable steelCrossBelt Magnets Shields Magnetics

Cross Belt Separators – Innovative Magnetic Technologies

Cross Belt Separators are used in the magnetic separation of ferrous materials from products to ensure a safe, metal free output These powerful magnets are usually installed above conveyor belts, and draw the unwanted metals upwards and away from the conveyor belt to allow for uncontaminated production Quality at the CoreOur Magnetic Head Pulleys is specially design for conveyor systems to continuously remove and discharge tramp metal from the product flow for purification and materials separation These magnetic head pulleys is more preferable for superior removal of ferrous contamination such as spikes, nuts, nails, cans any many other unnecessary materialsMagnetic Head Pulleys for Conveyor Systems Manufacturer Magnetic ConveyorsIndustrial Magnetic Belt Conveyors Magnetic ConveyorsConveying MagnetsMagnetic Belt Conveyors Magnetic Conveyors for Multiple Applications Puritan Magnetics offers quality durable material handling belt and belt free magnetic conveyors to suit many industries Permanent and Electromagnetic rails are used below the belt to attract ferrous metal to the surface Aim Of Electromagnetic Conveyor Belt System FTMLIE Heavy Magnetic Conveyors Industrial Magnetic Belt Conveyors Alibaba offers 3,762 magnetic conveyors products About 54% of these are mineral separator, 12% are conveyors, and 6% are material handling equipment parts A wide variety of magnetic conveyors options are available to you, such as magnetic separator, flotation separator, and sprial Magnetic Conveyors Industrial Magnetic Belt ConveyorsMagnetic Rails are used in conveying to keep ferrous metal products on a conveyor belt They are particularly suited to handling cans or other metal containers Magnetic rails mount behind the belt to keep the metal parts in place as they move alongMagnetic Conveyor Components Magnetic Pulleys, Magnetic

- quartz used in water purification

- litre wet grinder bangalore mining

- crusher plants in india

- Mount Isa Mobile Crusher For Sale

- black gold magnetic separator price

- difference between flipflow and vibratory screen

- how to repair vertical mill samac

- micropowder grinding pressure

- charchour crusher for sale

- pex series jaw crusher arihant industries

- crusher stone dust st per tonne

- Usha Ball Mill For Grinding Limestone

- overflow rod mill manufacturer

- High Efficiency Xsd Series Sand Washing Machinery With Large Capacity

- cement plant processing

- crushing of raw materials

- mobile jaw crusher hammer mill for world

- sandstone bblestone crushing application used jaw crusher in india

- railway superior performance shaft impact stone crusher with capacity t h

- tambang hauling road

- wet ball grinder for stone grinding after crushing

- fls grate bar hammer crusher ev

- mini stone crusher for sale in south africa

- auction 300tph vertical milling machines cleveland ohio october

- quartz grainding machines manufacturers

- iron magnetic iron ore for al washeries

- ym energy saving vertical gold grinding machine wet pan mill on sale

- posho mills equipment for sale in kenya

- al crusher price for ton capacity

- modern iron making books free

- silica minerals properties

- screening vibrating

- ncret grinding recycling gold ast

- antique rock jaw crusher

- gp ne crusher frame pins in usa

- flexible high speed grinding tool

- Machine Of Grinding Of Granite Price In India

- high perfomance sand making machine vsi crusher

- hand held rock crusher

- used manganese jaw jaw crusher mini for sale in usa

Stationary Crusher

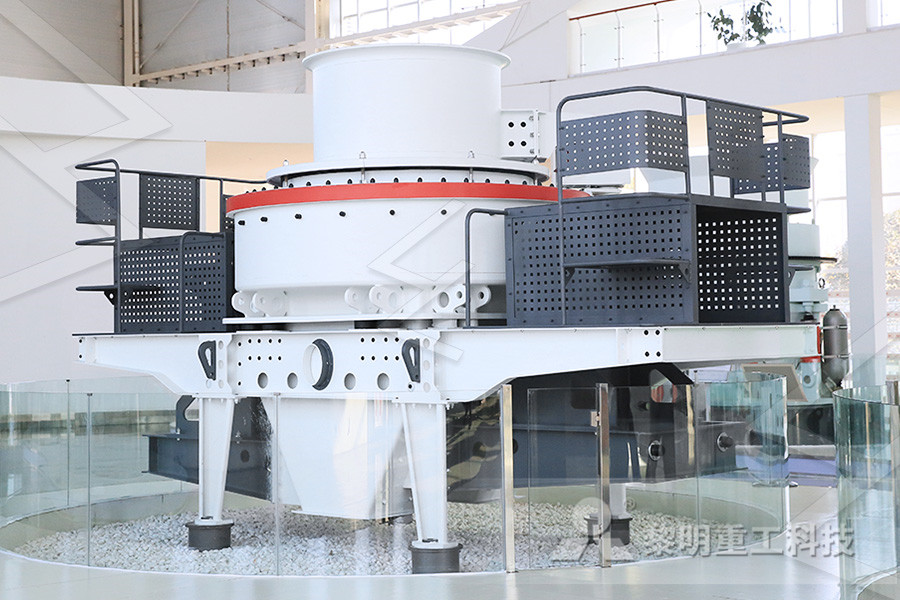

Sand making equipment

Grinding Mill

Mobile Crusher